CONFIGURATIONS FOR INDUSTRIAL AIR FILTRATION

Before you select an industrial dust collector, it is important to understand how your air filtration system will be configured. There are several configuration options for both source capture and ambient air filtration. We can also design a hybrid system that combines both source capture and secondary ambient air filtration or ventilation. We have outlined some of the most common configurations below.

Ambient Dust Collector Configurations

Industrial dust collector configurations for ambient air filtration and industrial ventilation.

Ambient air filtration or ventilation cleans air for the whole facility. It may be used alone where source capture is not possible or in combination with source capture methods for large point sources. In an ambient air filtration system, dirty air is pulled into an industrial dust collector and clean, filtered air is returned to the facility. Ambient ventilation solutions exhaust dirty air to the outside and pull in clean make-up air.

Push-Pull Configuration

A ducted push-pull ambient air filtration system uses a centralized dust collector (or a pair of dust collectors) and a system of overhead ductwork to circulate air through the entire facility. The ductwork creates a continual airflow pattern in the facility, “pulling” dirty air in through one side of the facility and “pushing” clean, filtered air out on the other side. Because ductwork can be located out of the way at the sides of the facility, this configuration works well in environments where source capture is not possible due to overhead cranes or other obstructions.

Benefits:

- Cleans and circulates air for the entire facility and keeps heated or cooled air inside.

- Reduces environmental emissions and energy losses associated with exhaust ventilation.

- Ideal for applications where source capture is not possible or practical.

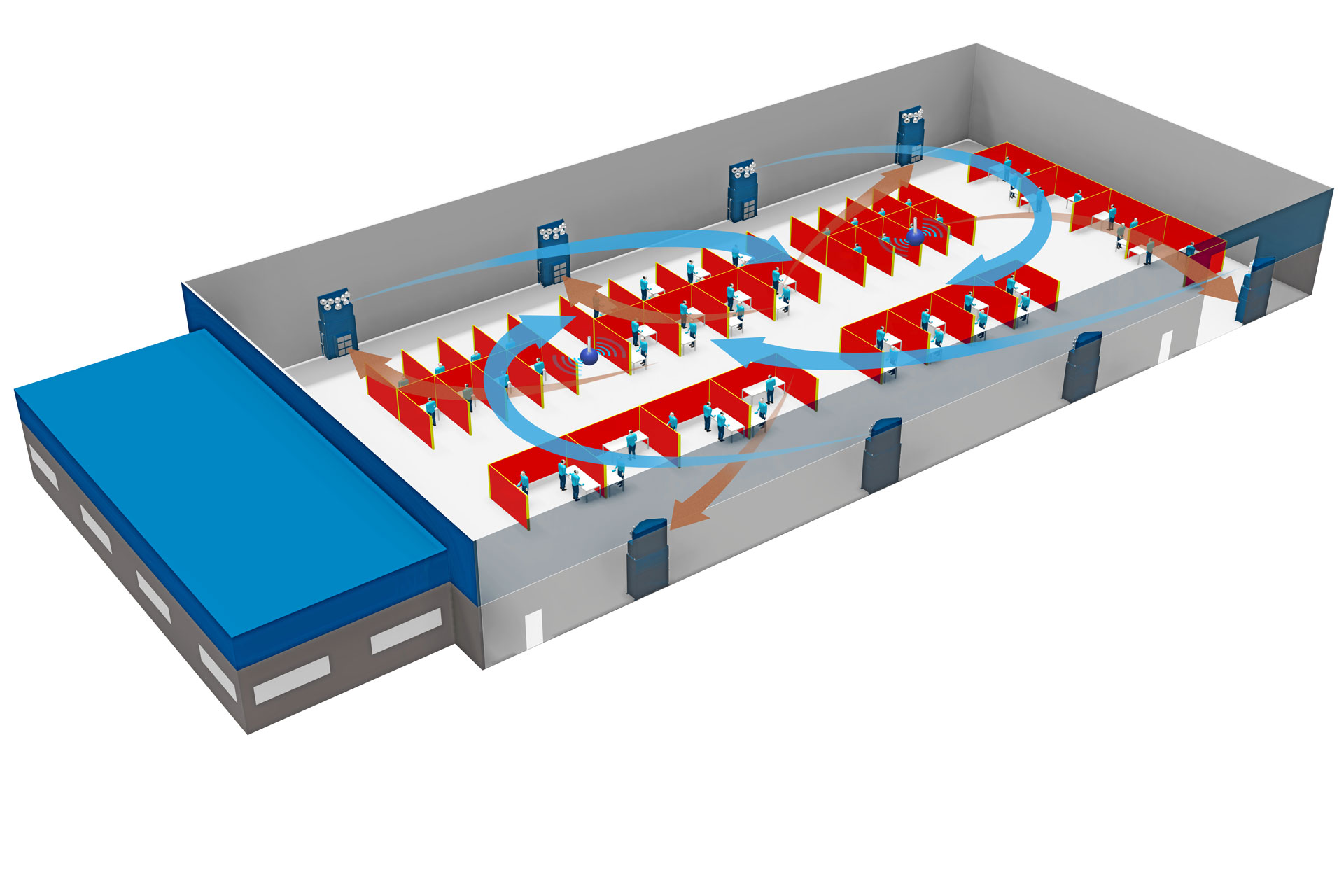

Vortex Configuration

The vortex configuration uses free-standing filtration systems (such as RoboVent Vortex) placed strategically throughout a facility. The intakes on the units are placed close to fume generation sources and the exhaust is pushed through punkah louvers to direct air and create mixing throughout the facility. The units are strategically placed to create circular airflow patterns that pull air away from workers and provide a continual supply of clean, filtered air.

- Does not require any ductwork, making the system more flexible and easier to install.

- Reduces environmental emissions and energy losses associated with exhaust ventilation.

- Ideal for applications where source capture is not possible or practical.

Exhaust Ventilation

Exhaust ventilation systems are used to dilute contaminants in the air by exhausting dirty air to the outside and bringing clean air in. Large exhaust fans are placed on the roof of the facility to exhaust air out of the building. Make-up air units then return clean air back into the building. This is a simple solution to improve air quality and reduce exposure to dangerous airborne contaminants. Note: exhaust ventilation should not be used if exhausting contaminated air will put the facility out of environmental compliance. Bringing large volumes of unconditioned air back into the facility may also drive up heating and cooling costs.

Benefits:

- Low initial cost and easy installation compared to dust collection systems.

- Dilutes airborne contaminants to reduce exposure.

- Provides fresh outdoor air.

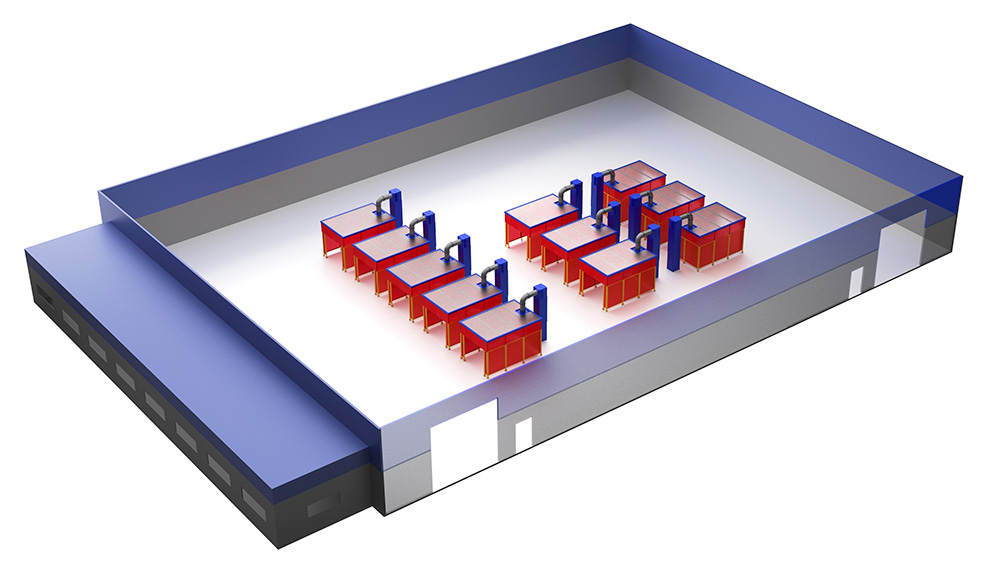

Source Capture Dust Collector Configurations

Industrial dust collector configurations for source capture air filtration.

Source capture systems collect dust, smoke and fumes from point generation sources, such as a weld cell, laser cutting machine, CNC, or manual welding or grinding station. Fumes are collected using a fume arm, hood or backdraft plenum that is ducted to a dust collector. RoboVent designs hoods specifically for each application. There are several hood types.

- Enclosing hoods (such as the Streamline Hood) completely enclose the application. Ideal for robotic welding cells and other robotic processes.

- Close capture hoods are located next to an emission source without enclosing it. They actively pull air in from the source. They are often used for manual processes (such as manual welding or grinding) to pull contaminated air up and away from the worker.

- Receiving hoods are designed to “catch” emissions that are already in motion, such as hot air rising from a melting furnace or other hot process. A canopy hood with a fan can be used to direct emissions into the dust collection system.

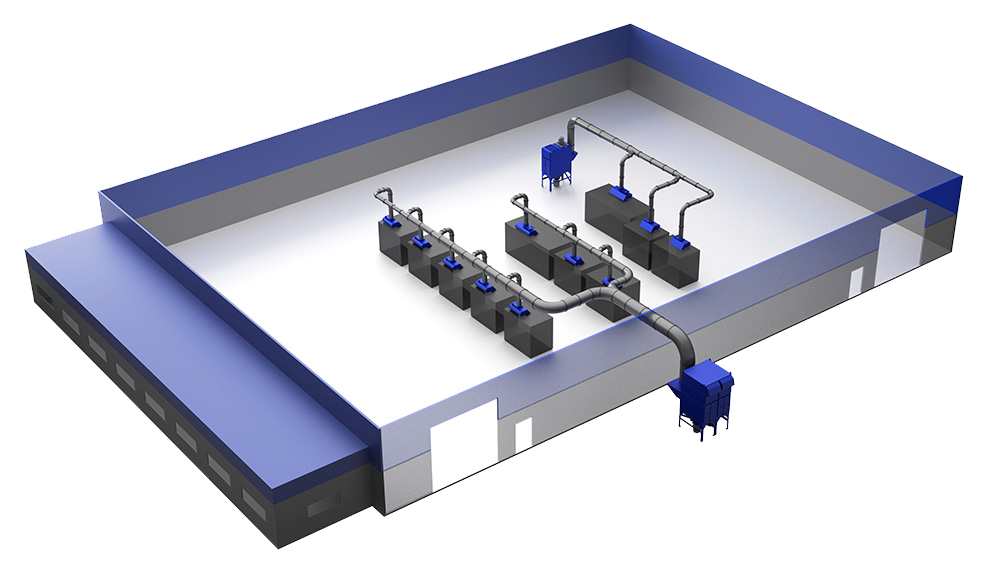

Traditional Ducted Source Capture System

In a traditional source capture system, multiple fume generation sources are ducted to a single dust collector, which may be located inside or outside the facility. Each generation point is captured at the source and then conveyed through ductwork to a central collection or exhaust system. The dust collector must be sized for the total fume production of the facility. This configuration can be used with any hood or source capture method.

Benefits:

- There is only one dust collector to purchase, operate and maintain for multiple weld cells or generation sources.

- The dust collector can be located outside to save floor space and reduce noise in the facility.

- Can be designed and optimized for the specific application to reduce energy use and operating costs.

Hi-Vac Grid Configuration

The Hi-Vac Grid Configuration is a modular system that combines the efficiency and energy savings of a centralized ducted source capture solution with the flexibility to move components as needed. It's a whole-facility solution consisting of modular, standardized ductwork and components that can be easily reconfigured as your needs change.

Benefits:

- The ducted grid system only needs 70% of the airflow used by individual units, delivering significant energy savings over time.

- Standardized, modular components make it easy to install and easy to reconfigure as needs change.

- Our Smart Gate™ Auto Cleaning system directs airflow to clear debris from the system automatically, reducing manual cleaning requirements.

FloorSaver Configuration

Maximize your floor space with the FloorSaver System. This innovative RoboVent collector stacks directly on top of a welding cell hood. This configuration frees up significant floor space for other equipment or traffic needs. Must be used with enclosing hoods.

Benefits:

- Stacks the dust collector on the top of the cell for maximum floor space savings.

- Easily moves with the enclosure if you need to change your layout.

- Eliminates the need for extensive ductwork.

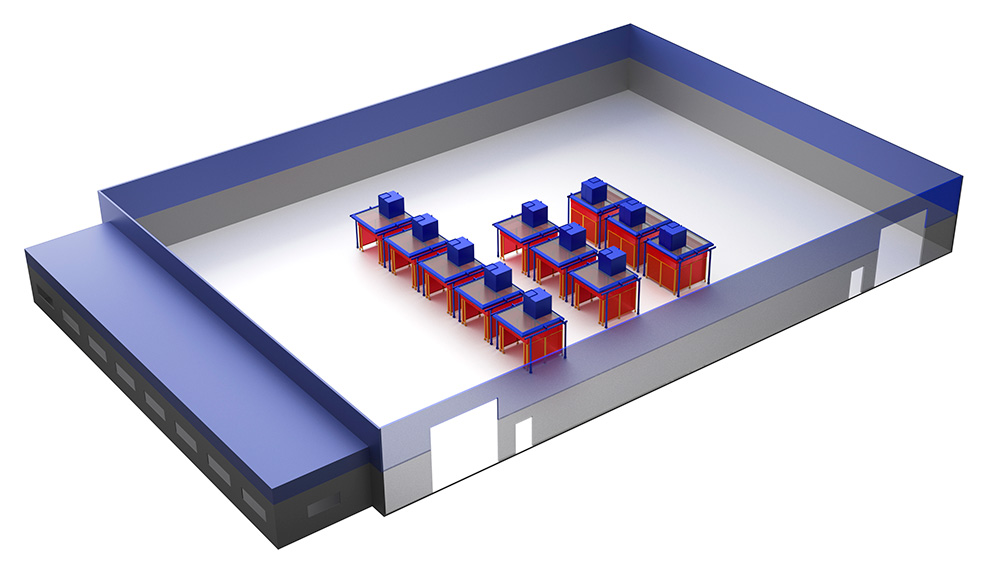

Spire Configuration

RoboVent Spire is a powerful, flexible dust collector that can be ducted to one or two fume generation sources, such as a weld cell, CNC machine or laser cutter. The Spire Configuration is flexible, simple to install and easy to maintain. The Spire dust collector has a very small footprint—about the same size as a wire barrel—to save floorspace. The units can be ducted to any style of source capture hood.

Benefits:

- This configuration grows with you—you can add new Spire units at any time to expand production capacity without changing your entire dust collection system.

- Spire units are easy to move with your weld cells if you need to change your production layout.

- Since each unit is ducted only to one or two nearby generation sources, there is no need for extensive facility-wide ductwork.

Hybrid Configurations

Hybrid configurations combine multiple air filtration technologies (such as source capture/ambient or ambient/ambient) to optimize indoor air quality. Typically, source capture is used to collect emissions from large point sources. The ambient air filtration or ventilation solution is layered on to collect any remaining emissions. A hybrid system is often used when:

- Point sources cannot be fully enclosed, allowing some emissions to escape.

- Manual welders are using fume arms, fume extraction guns or backdraft tables for primary collection and secondary air filtration is needed to collect the fumes these methods miss.

- Emissions are especially hazardous and PELs cannot be met through source capture alone.

- There are secondary, diffuse emission sources in addition to the large point sources (e.g., cooling bins).

Fume Extraction Gun and Hi-Vac Unit with Secondary Ambient Filtration

For manual welding, a fume extraction gun can be an effective point source capture solution. The fume gun captures up to 95% or more of emissions from the weld seam before they enter the breathing zone. For small operations with intermittent welding, this may be enough by itself. However, in high-production environments, the remaining 5% of weld fumes can build up to unacceptable levels in the ambient air. In these cases, a secondary ambient filtration system is recommended. Any of the ambient systems (ducted push/pull, Vortex, or exhaust ventilation) may be used.

Hooded Source Capture with Secondary Ambient Filtration

Hooded source capture is highly effective at collecting fumes from enclosed point sources such as robotic welders or batch mixers. In many manufacturing facilities, there are also secondary, diffuse emission sources in addition to the large hooded applications. Because the hoods only capture fumes from activities within the enclosure, a secondary system may be needed to collect dust and fumes from other activities. For example, robotic welders may be enclosed in hoods ducted to individual Spire or FloorSaver units, while Votex units or a ducted push-pull ambient filtration system collects emissions from less intensive applications, such as manual metalworking. This system can offer the best of both worlds, preventing heavy fumes from intensive applications from propagating through the building while enabling a more open environment for other types of work.

Dual Ambient Air Filtration

A ducted push-pull ambient system can be combined with a secondary Vortex or exhaust/makeup air system. This may be done to minimize the cost of a ducted push-pull system, address different air filtration needs in different parts of the building, or handle environments that do not allow for ductwork in all parts of the building. For example, it may be desirable to have a ducted push-pull system directly over the main production lines and supplement with exhaust ventilation in other parts of the facility that are not directly impacted by emissions. Or, in cases where ductwork cannot be installed everywhere, Vortex units can be used as supplemental air filtration in areas that the ducted system cannot reach.

Multiple Source Capture Systems

There are many cases in which multiple source capture systems are used. Many manufacturing facilities have multiple types of production happening under one roof. They may have large robotic systems under hoods, manual welding using fume extraction guns, and other processes using fume arms or backdraft plenums to pull fumes away from workers. All of these source capture solutions can be combined in one system. They may be ducted to a single large centralized dust collector or different parts of the facility may use smaller individual dust collectors.