DUST AND FUME COLLECTION CHALLENGES IN THE TRANSPORTATION EQUIPMENT INDUSTRY

The Occupational Safety and Health Administration (OSHA) has issued regulations for fume and dust levels since the early 1970s. These regulations are updated from time to time. Recently, manufacturers of heavy equipment have needed to pay special attention to changing standards on weld fumes—in particular, the standard for manganese. Manganese particles are a common component of weld fumes. Because these particles are extremely small—due to the high temperatures involved in welding—they are easily inhaled. While manganese is actually a necessary part of one’s diet, when inhaled at certain concentrations, it is highly toxic. Exposure to inhalable manganese in even small quantities can affect memory and reaction times. Chronic exposure can have serious effects on the central nervous system, including manganism. This condition has symptoms similar to Parkinson’s Disease. OSHA regulates workers’ exposure to other weld fume components, as well, including hexavalent chromium and beryllium. Exposure to these substances carries serious risks, as well, from major respiratory problems to cancer.

The Occupational Safety and Health Administration (OSHA) has issued regulations for fume and dust levels since the early 1970s. These regulations are updated from time to time. Recently, manufacturers of heavy equipment have needed to pay special attention to changing standards on weld fumes—in particular, the standard for manganese. Manganese particles are a common component of weld fumes. Because these particles are extremely small—due to the high temperatures involved in welding—they are easily inhaled. While manganese is actually a necessary part of one’s diet, when inhaled at certain concentrations, it is highly toxic. Exposure to inhalable manganese in even small quantities can affect memory and reaction times. Chronic exposure can have serious effects on the central nervous system, including manganism. This condition has symptoms similar to Parkinson’s Disease. OSHA regulates workers’ exposure to other weld fume components, as well, including hexavalent chromium and beryllium. Exposure to these substances carries serious risks, as well, from major respiratory problems to cancer.

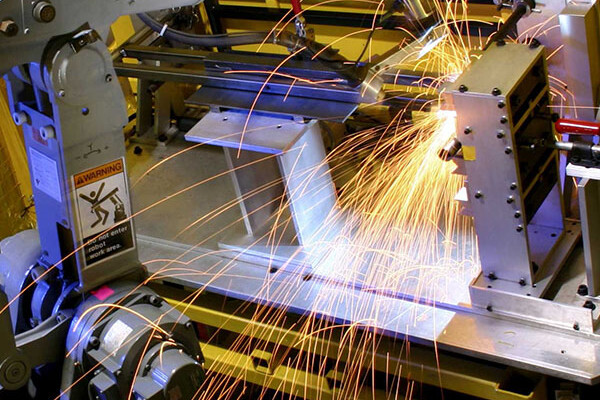

The manufacture of transportation equipment is challenging from an air quality perspective because so much of the welding is performed on large weldments. When welders move along a large weldment, it is often difficult to capture the weld fumes produced. Constantly moving a fume arm is often impractical, or at the very least inconvenient. Welders, under pressure to meet deadlines, often fail to keep up with fume capture. Whether a facility is producing automated streetcars or traditional buses, the pieces are large, and the challenges are similar.

Today, manufacturers face yet another challenge: attracting and retaining skilled workers. Young workers are not entering the trade as they did in the past. The American Welding Society estimates that manufacturers will see a shortage of 290,000 skilled workers by 2020. Maintaining a pleasant and safe workplace will help manufacturers attract and keep the best workers.

Related Resources

SOLUTIONS FOR DUST AND FUMES IN THE TRANSPORTATION EQUIPMENT INDUSTRY

RoboVent understands transportation equipment manufacturing and has a solution for every application. Whether you’re constructing freight cars or passenger cars, subways or buses, RoboVent understands welding and the air quality challenges that come with it. For decades, RoboVent has designed and manufactured the best air filtration equipment available. For example, RoboVent’s line of portable collectors lets you capture dust and fumes at their point of creation. These collectors use fume arms or hoods to make sure welders are protected, as well as everyone in the facility. These collectors are especially useful when welding or cutting large components.

RoboVent’s MIG fume gun is another cutting-edge solution to weld fumes. Welders working on large weldments find the Extractor a powerful, lightweight solution for delivering the perfect weld while collecting weld fumes at the source. The Extractor is a revolutionary leap in fume gun technology and promises to reshape the welding of heavy equipment.

For a larger or facility-wide solution for fumes and dust, RoboVent created the Fusion Series of collectors. This system is designed to save energy while delivering the finest filtration possible. If your operation is large—or growing—you can scale up the collection efforts with the Grid Configuration. This is a ducted array of collectors that offers even more efficiency—the grid uses 70% of the airflow of the individual units combined.

RoboVent also offers exceptional protection from fire and explosion, as well. For example, the Delta 3 spark arrestor and the Supprex-200 Fire Suppression System stop fires before they start. These systems protect workers, property and production lines.

As always, RoboVent guarantees satisfaction. Our manufacturing standards are the highest in the industry, and our warranty is the best in the business.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.