VISTA360™ SERIES

DISCONTINUED; SERVICE AND PARTS STILL AVAILABLE

Need a powerful ambient air filtration system? Vista360™ has been discontinued, but we can still help you find the right ambient solution for your facility. Whether you need a traditional ducted push-pull system or a ductless floor-mounted system, we’ve got you covered.

WE RECOMMEND:

LOOKING FOR PARTS AND SERVICE FOR YOUR VISTA360™ SERIES COLLECTOR?

At RoboVent, we stand behind all of our dust collectors for as long as they are in service—and with our commitment to manufacturing excellence, we anticipate that will be for a very long time indeed. If your Vista360™ is in need of parts, service, or repair, we’ve got you covered.

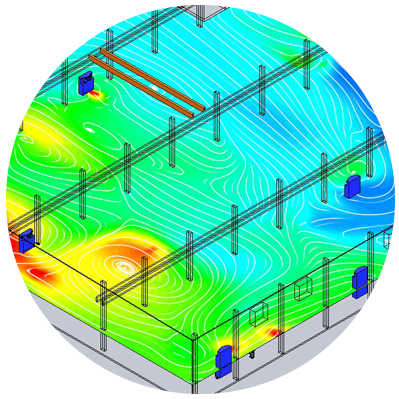

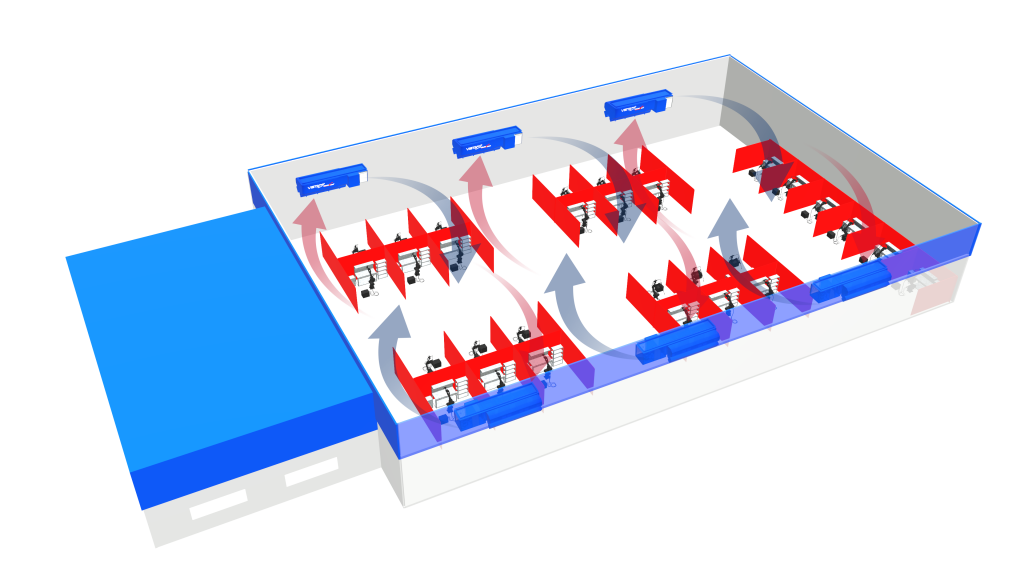

VENTMAPPING™: OPTIMIZING AMBIENT AIR FILTRATION

Our VentMapping™ engineering service is a proprietary, scientific approach to air filtration system design. Using advanced analytical methods, including Computational Fluid Dynamics (CFD), we model your current airflow patterns and contaminant levels and design a system around your unique facility layout, contaminant sources and air quality goals. VentMapping can be used to optimize placement of your dust collectors and maximize the effectiveness and efficiency of your system.

VISTA360™ FEATURES:

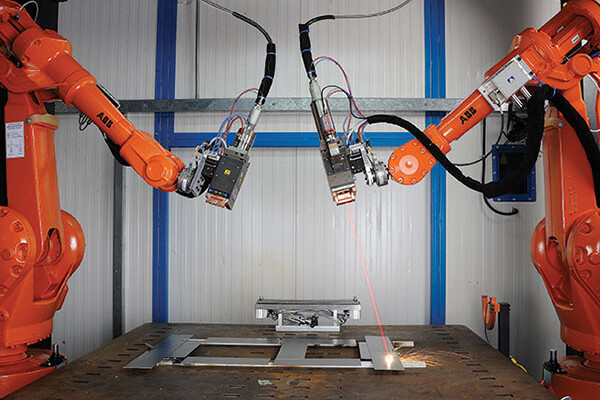

Vista360's other distinguishing feature is the manner in which it is installed—on the ceiling, out of the way of other equipment and traffic. Freeing up floor space allows you to keep your production lines flexible. Sight lines are much improved across the plant floor, as well.

VERY LOW MAINTENANCE: RoboVent collectors are designed for fast filter changes and low maintenance. And our Pad Control Panel makes maintenance headache-free.

OVERHEAD INSTALLATION: Locating the filtration equipment overhead keeps your floor open and flexible.

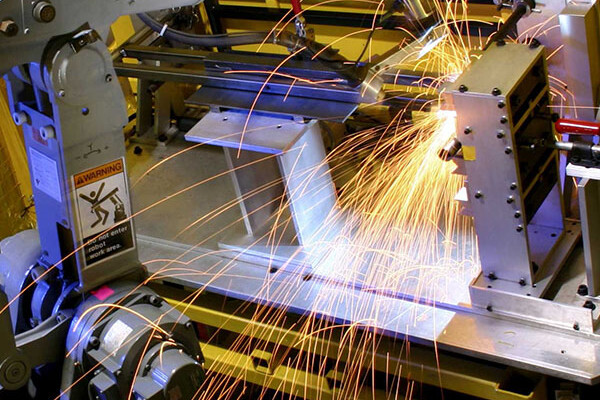

BUILT-IN SPARK ARRESTANCE: The optional Delta3 spark arrestance system can be added to the Vista360 for superior fire safety.

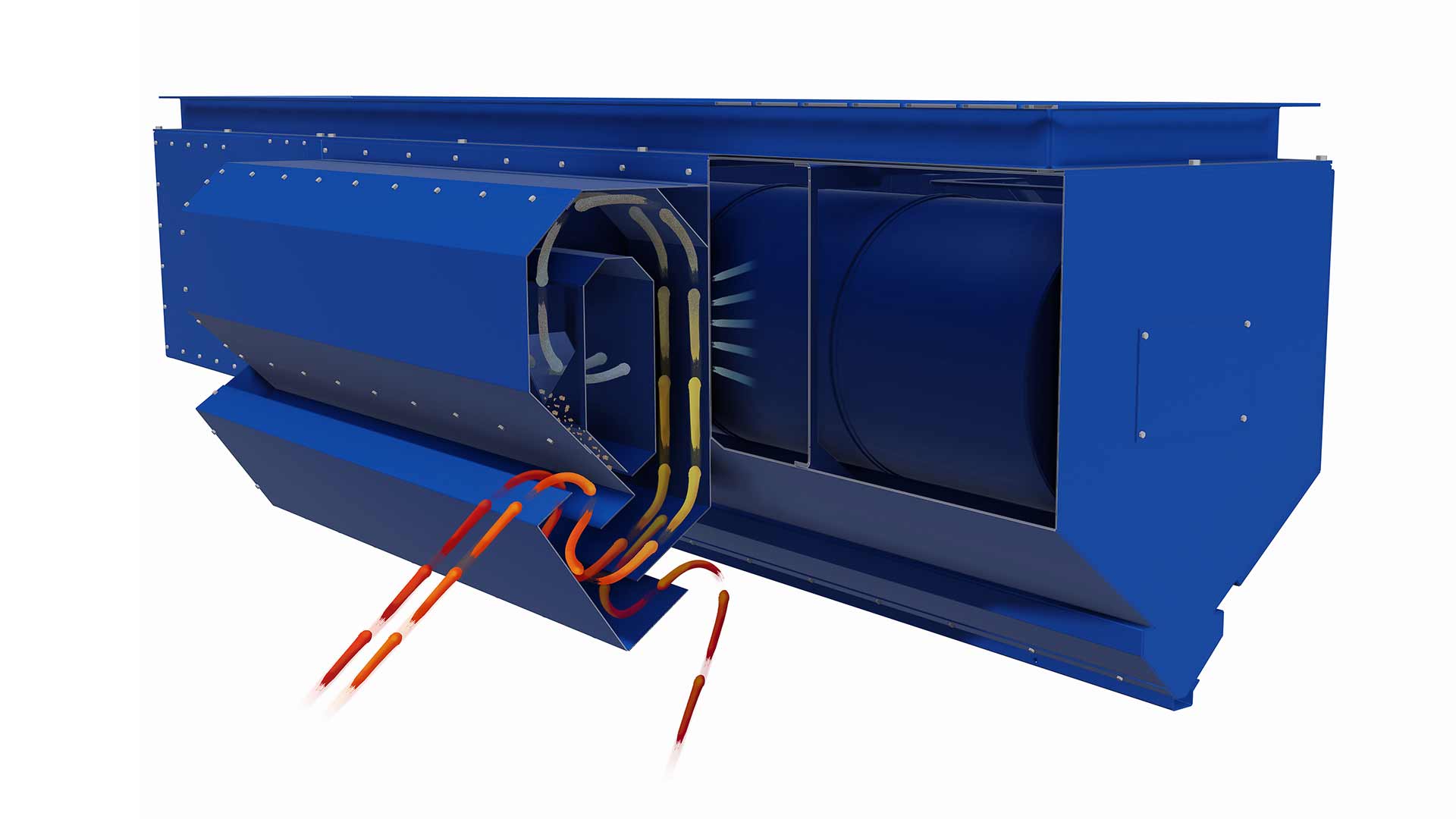

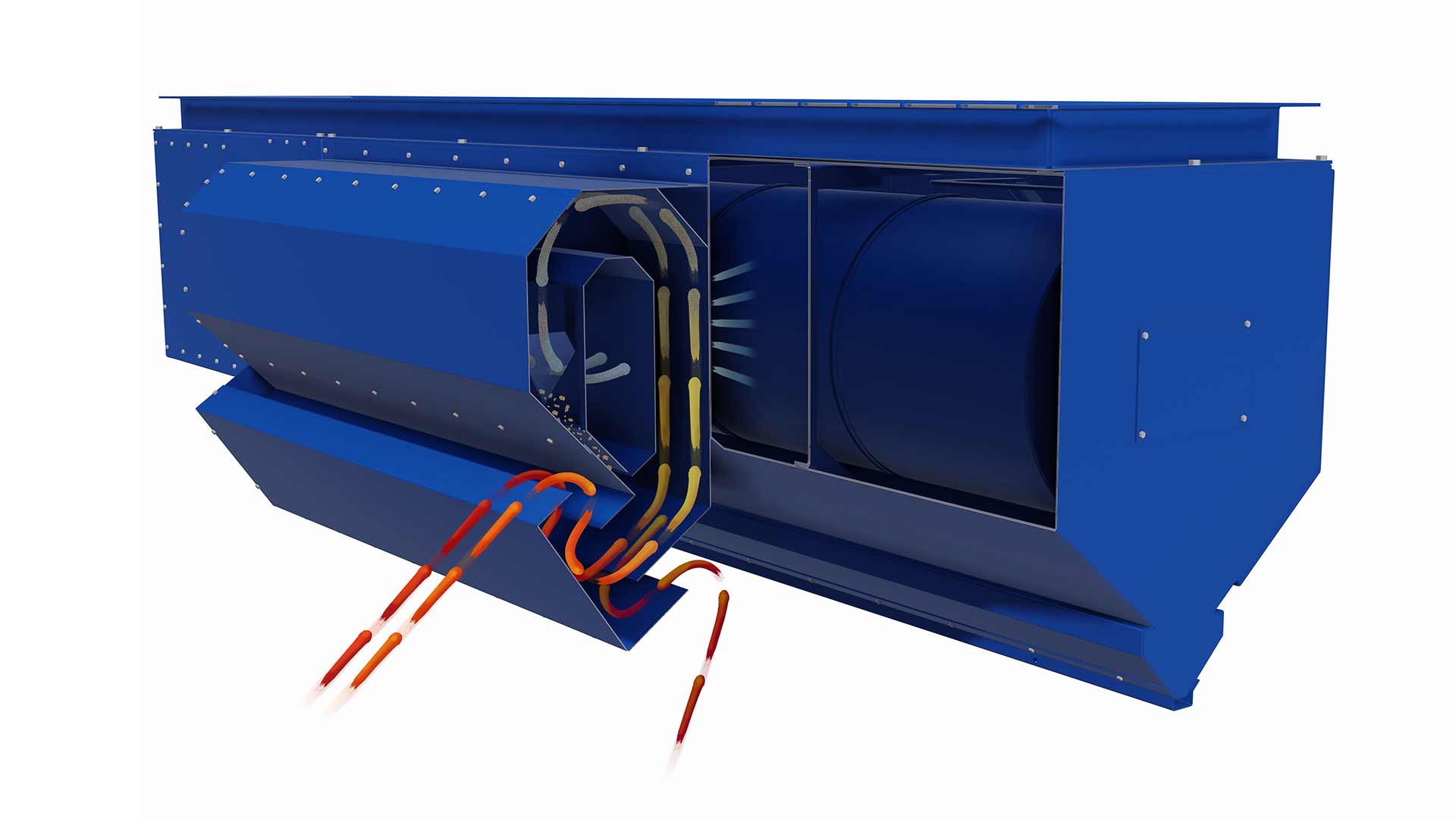

HOW IT WORKS

EPAD CONTROL PANEL: Each Vista360 unit comes standard with ePad, an easy-to-use touch-screen panel putting system controls right at your fingertips.

SAFESENSOR™ PARTICULATE MONITORING: SafeSensor is our advanced particulate-monitoring device that can detect leaks past the filters. If one should occur, SafeSensor will shut the equipment down and trigger an alarm.

DELTA3™ SPARKOUT: Option: Our proprietary Delta3 spark arrestance system can be added for superior fire safety. Delta3 uses centrifugal force to eliminate sparks at the source.

CLEAN AGENT GAS FIRE UPPRESSION SYSTEM: Option: This is a dual-stage system activated by smoke or heat. If smoke is detected, a fire damper closes, stopping all airflow and oxygen supply. If heat is detected, a clean agent gas is instantly deployed.

EDRIVE™ AUTOMATIC VFD: Option: The eDrive constantly monitors airflow and automatically adjusts the motor RPM to compensate for filter loading. Energy peaks and valleys are evened out, and energy use is cut by 20% to 30%, while filter life is extended by as much as 30%.

VISTA360 CONFIGURATION

Save Critical Floorspace

Vista360 units can be attached to ceiling, hung from trusses or affixed to other applicable structures throughout the plant – all of which help conserve valuable floorspace. Typically, they are hung above dust producing processes and placed strategically throughout the facility based on appropriate airflow and dust patterns in order to be most effective.

OPTIONAL DELTA3™ SPARK ARRESTOR

Delta3™ is built on groundbreaking technology that uses centrifugal force to kill sparks before they have a chance to ignite. By stopping sparks right at the source, Delta3 creates a safer work environment and vastly reduces the risk of avoidable work accidents. And our innovative design will help you keep productivity high, operating costs low, and maintenance costs to a minimum.

DROP US A LINE

Contact RoboVent today to start building your custom dust collection system.