Spark Arrestors for Dust Collection and Air Filtration Equipment

If your applications produce sparks, spark arrestance is a critical element of dust collector fire prevention. RoboVent offers a range of spark control options, including our industry-leading Delta3™ Inline Centrifugal Spark Arrestor. We also offer dust collector intakes with integrated wire mesh and/or baffle systems for our leading dust collection systems. Ask us which spark arrestance technology is right for you!

DO YOU NEED SPARK CONTROL?

If your processes produce sparks, the answer is probably yes. Spark arrestance is typically needed for dust collection for applications such as:

- Welding

- Cutting/Laser Cutting

- Grinding/Filing

- Abrasive Blasting/Wheel Blasting

- Shot Peening/Surface Texturing

- Spark Machining/Electrical Discharge Machining (EDM)

WHICH KIND OF SPARK CONTROL SYSTEM IS RIGHT FOR YOU?

Choosing the right spark control system for your dust collection system is important. Options for spark control include centrifugal spark arrestance systems, mesh or screen-type spark arrestors, baffle systems, strike plates and dropout boxes. The right choice for effective spark arrestance depends on many factors, including:

- The volume of dust you are collecting and the characteristics of the dust (particle size/weight distribution, etc.)

- The number of sparks created

- The likelihood of those sparks entering the dust collection system

- Airflow requirements for your applications

- Other risk factors for your processes (explosive environment, combustible dust, etc.)

Read more about spark control options for dust collection systems.

Centrifugal Spark Arrestors

Centrifugal spark arrestance provides highly reliable spark control for applications producing large numbers of sparks. The Delta3™ Inline spark arrestor is our flagship product for reliable spark suppression and control. We can help you choose the right spark control solution.

DELTA3™ INLINE SPARK ARRESTOR

The Delta3 Inline Spark Arrestor offers unbeatable spark arrestance with exceptionally low pressure drop. Delta3 Inline uses centrifugal action to drive sparks and embers against the walls, stripping them of their thermal envelope. In rigorous comparative tests, Delta 3 Inline:

- Allowed zero sparks through at all tested airspeeds.

- Tied for lowest pressure drop among all tested technologies.

ADDITIONAL SPARK CONTROL OPTIONS

We offer intakes with integrated spark control for our leading dust collector models, including Senturion™.

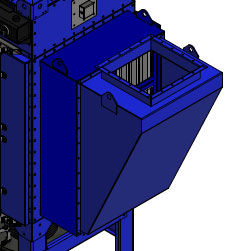

IPB Ducted Intake

IPB Ducted Intake

A duct attachment intake installed on the side of the collector. A series of mesh panels and baffles are included to reduce spark passage into the filter cabinet.

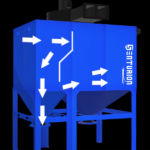

Vortex SAP Intake

Vortex SAP Intake

An ambient air intake installed on the collector to allow dust and air into the filter cabinet. A series of mesh panels and baffles are included to reduce spark passage into the filter cabinet.

Dropout Box

Dropout Box

A dropout box (or inertial separator) removes heavy particulate from the airstream before it enters the filter chamber, allowing larger sparks and embers to fall out naturally.

Need a detect-and-suppress system?

For explosive environments and high-risk applications where 100% spark suppression is required, a detect-and-suppress system may be needed. We can help you evaluate the need for a detect-and-suppress system and connect you with one of our industry partners.