FREQUENTLY ASKED QUESTIONS

About industrial dust collection best practices, regulations and industries that are affected by dust, fumes, smoke and mist collection.

Regulations & Compliance

How Often Do OSHA Regulations Change?

The simple answer is: often enough to cause concern. Because the process of changing the legal code is so complicated, these changes don’t come according to a regular schedule—but when they do, they can cause serious waves in the manufacturing sector.

When OSHA changes a regulation, it sets a timetable for implementation, explains how it will be enforced and so on. The agency will typically allow months—if not years—for employers to adjust to the new rule. While this may sound generous, if a change in regulation is significant enough, it will likely require quick and serious action from an employer.

A good example of such a change came in 2016 when OSHA changed its regulation of crystalline silica. The agency determined that the existing permissible exposure limit (PEL) for the substance was not adequately protecting workers and cut the limit in half. Manufacturers are still scrambling to adapt to the change.

How Are OSHA Regulations Different From EPA Ones?

While the Occupational Safety and Health Administration (OSHA) regulates workplace safety, the Environmental Protection Agency (EPA) sets rules to limit environmental pollution. A manufacturer that produces contaminated air in any serious volume should be aware of both sets of regulations.

OSHA’s regulations for air quality often come in the form of permissible exposure limits (PEL’s) for workers. These standards limit how much of a certain substance a worker can be exposed to over a typical shift. If exposure exceeds that limit, an employer can be cited and possibly fined. OSHA maintains ten regional field offices, as well as area offices in most states, to inspect facilities, help employers meet the regulations and enforce the rules in case of noncompliance.

The EPA’s regulations are different—most of the relevant standards for manufacturers are based on the Clean Air Act. These regulations limit how much of a particular substance a company can release into the environment. Their concern is the health effects of these substances on the surrounding community. The EPA maintains a list of air emissions sources:

- Nitrogen Dioxide (NO2)

- Ozone (O3)

- Sulfur Dioxide (SO2)

- Particulate Matter (PM)

- Carbon Monoxide (CO)

- Lead (Pb)

Some of these limits affect typical manufacturers. If a facility is producing contaminated air—say, through a large welding operation—and exhausting all of it to the outside, the company may be breaking EPA regulations. Failure to comply could lead to citations and penalties.

How Are OSHA And ACGIH Different?

In short, OSHA is a federal agency that regulates workplace safety, while the ACGIH is a scientific organization that studies occupational and environmental health issues. While the two are very different in structure and mandate, they have a relationship that is relevant for manufacturers.

OSHA, or the Occupational Safety and Health Administration, was signed into law by President Richard Nixon in 1970. The agency began work in 1971 with the mission to “assure safe and healthful working conditions for working men and women by setting and enforcing standards and by providing training, outreach, education and assistance.” Over the years, OSHA has added regulations to the legal code, most of which are contained in Standard 29 CFR Part 1910 Subpart Z. Many of these regulations set limits for worker exposure to various substances. These limits are often expressed as “permissible exposure limits,” or PEL’s. Workplaces must comply with these regulations or risk citations and fines.

OSHA oversees roughly seven million workplaces. The agency is organized under the Department of Labor and has ten regional offices, as well as area offices in most states. You can find OSHA’s frequently asked questions here.

The American Conference of Governmental Industrial Hygienists, or ACGIH, is a nonprofit organization established in 1938. Their motto is “Defining the Science of Occupational and Environmental Health.” Made up of a core of industrial hygiene workers, they collect and share information to support this goal. The organization also publishes the well-known reference work TLVs and BEIs. This annual guide for “evaluation and control of workplace exposures to chemical substances and physical agents” contains TLVs® (Threshold Limit Values, or exposure guidelines for over 700 chemical substances) and BEIs® (Biological Exposure Indices, or limits on over 80 more substances).

A TLV does not have any regulatory power in the workplace, but the number is still significant. It serves an advisory role to OSHA and to manufacturers who care about workplace safety. The ACGIH’s recommendations reflect the field’s latest research and expert analysis, so OSHA looks to it to inform its regulations. For example, if the ACGIH chooses to lower its limit for a particular substance, it is likely that OSHA will at least consider the issue. OSHA is under many conflicting pressures, so it is not an agency that acts quickly, but ACGIH recommendations are an influence on the agency. Some manufacturers who want to stay ahead of regulations and protect their workers according to the latest science follow ACGIH’s recommendations for exposure limits.

Why Can’t I Just Exhaust My Dirty Air To The Outside?

The primary risk to exhausting contaminated air to the outside—besides possibly adversely affecting the community—is breaking air quality regulations of the Environmental Protection Agency (EPA). These regulations apply to the environment, rather than to workplace air, which OSHA regulates. If too many contaminants are put into the air in too short a time, your company might have a compliance problem.

Another problem with exhausting dirty air is that it often encounters a lot of workers and equipment on its way out the building. If the air is carrying toxic substances, those workers will be exposed, risking their health and OSHA compliance. Dirty surfaces can cause slip hazards, unsightliness, and malfunction problems with equipment.

A less critical but still common problem with exhausting dirty air is the prevalence of dirty roofs where exhaust vents are located. Besides being unsightly, this creates an extra housekeeping burden.

Which Is Better For Meeting Air Quality Regulations: Source Capture Or Ambient Capture?

The question of source v. ambient capture primarily comes down to the nature of your air quality problems—namely, in the volume of fumes and the nature of the particulates. High-volume operations that produce a lot of dust or fumes are best served with a source capture solution. Failing to do so risks letting too many particulates drift around your facility, causing harm to workers and risking regulatory compliance. Equipment such as fume arms and backdraft tables are able to pull contaminants away workers as soon as they are produced. Robotic welding cells—one of the highest-volume fume producers—can be enclosed with a hood, allowing you to weld all day without filling your facility with fumes.

Contaminated air that contains a high quantity of toxic substances requires a more intensive air quality solution than more benign contaminants. For example, air that contains hexavalent chromium is much more dangerous than air that carries wood dust. The former air quality challenge calls for an intensive solution, such as source capture. You don’t want those toxic substances drifting through a facility waiting to be exhausted or to pass through an ambient capture system. While they drift, they could affect workers spread across a facility; and even a small level of exposure to these substances can cause harm.

Another factor affecting a decision regarding source or ambient capture is the layout of your facility. Overhead cranes or restricted floor space can limit your options. Sometimes an ambient capture system is the only option available. In situations like these, such a system could be paired with personal protective equipment.

Ambient capture solutions are great for facilities with operations spread across a wide area and with lower volumes of contaminants. These systems circulate the air throughout an entire facility and ensure that contaminants don’t linger and threaten workers. Applications that deal with less toxic substances are good candidates for ambient capture, as well, like the aforementioned wood dust. In these cases, an ambient capture system would both protect workers and guard against facility-wide dangers such as dust explosions.

Often, a hybrid system is worth considering. For example, in a facility where large pieces are being welded, a powerful source capture system—such as an enclosure and fume hood—might not be an option. In this situation, a fume extraction gun would be a good option for collecting most weld fumes at the source. A secondary ambient capture system would help ensure that nothing is missed. Today’s strict air quality standards demand this attention to detail.

How Can Engineering Processes Be Changed To Meet Air Quality Regulations?

One of the first steps in improving your air quality should be to look at changing your engineering processes. This is the “low-hanging fruit” that might save you a lot of trouble and expense. For example, it’s possible that cleaning a surface that gets welded or changing your weld wire might significantly reduce your weld fumes, avoiding the need for major ventilation equipment.

There are, in fact, several ways to improve your air quality before you resort to filtration and other such solutions. OSHA has collected some of these methods in their “Hierarchy of Controls,” an easy-to-use guide to adjusting your processes in ways that could solve your air quality problems.

- The first couple options in OSHA’s list are to remove the hazard or substitute something safer for it. Perhaps the process that produces the contaminant could be replaced with a less toxic process. New materials and processes are changing manufacturing every day, so new options might be on the table. An air quality expert could help you identify these opportunities.

- The next option is to change your engineering controls to cut or remove a threat to air quality. This includes the aforementioned adjustments in weld wire or shielding gasses, changes that can significantly reduce weld fumes or their toxicity. Changing from stick welding to MIG welding can also produce similar reductions. Isolating the process from workers is another solution. Robotic welding cells, for example, are a major step in protecting workers from direct contact with fumes. This method is also sometimes called “Prevention Through Design” (PtD). Why solve a problem when you can avoid it?

- Another option is to cut fumes through new housekeeping controls. For example, cleaning the residue on parts that are to be welded can significantly cut weld fumes. These solutions, and many others, are listed in OSHA’s Hierarchy of Controls.

Source:

OSHA’s Hierarchy of Controls: https://www.osha.gov/shpguidelines/hazard-prevention.html

Prevention Through Design: https://www.cdc.gov/niosh/topics/ptd/default.html

How Do I Get My Air Quality Tested?

Air quality audits are best conducted by licensed, third party professionals. These are usually industrial hygienists who understand manufacturing processes, regulations, data collection, health effects, and other relevant criteria.

Air quality audits are comprehensive and scientific. Most likely, the auditor will set up monitors throughout your facility to measure the contaminants. These sensors will be a few feet off the ground—around the height of the breathing zone and spread in a pattern that collects representative samples of air from throughout the facility. Monitors might also be attached to select workers in order to measure their exposures. These monitors will be attached to their uniforms, not far from their head to collect air near the breathing zone.

After collecting samples and data for a certain amount of time, the auditor will take them away for processing. Samples will be tested to determine what substances were in the air. Auditors will crunch the numbers and prepare a full report on your air quality.

Having a professionally conducted air quality audit by an independent source is valuable for a lot of reasons:

- First, it can let you know if your facility is safe for workers.

- Second, if your air quality is lacking in one area or another, the audit can help you develop a strategy for improving it. For example, air quality that is only slightly out of regulatory compliance demands a much different solution than air that is radically out of compliance.

- Third, if your air quality is great, it’s nice having that documented. It gives you something to brag about to new recruits. It is also nice to have in case of legal issues, if any should ever arise.

- Fourth, if your air quality is adequate but not great, it lets everyone know that the issue should be on their radar.

Taking steps to improve your air quality isn’t just great for employees’ health and productivity, it also helps prepare you for any regulatory changes that might occur. It’s always better to make investments when you want them, rather than being told by others that you need to make them.

What Is A TWA?

A TWA is a time-weighted average and relates to a worker’s exposure to harmful substances. The Occupational Safety and Health Administration (OSHA) sets their permissible exposure limits (PEL’s) as TWA’s. In short, a worker’s exposure level is averaged over a certain time period—usually a typical eight-hour shift during a 40-hour workweek.

The TWA allows for natural irregularities in a worker’s day. As the worker moves throughout a facility and engages in different activities, their exposure levels will rise and fall. Sometimes their exposure will even briefly exceed the legal PEL. OSHA sets a number for that, as well, or the “acceptable maximum peak above the acceptable ceiling concentration for an 8-hr shift.” OSHA lists a concentration and a maximum duration for this figure. But the key number to focus on is the averaged PEL. Averaging the worker’s exposure over time creates a more accurate measurement.

Source: definition of TWA in federal code is here

Source: OSHA’s annotated Z-2 table

How Do I Make Sure I Am Meeting OSHA PEL’s?

The first step in meeting a PEL is to understand your current air quality. Doing an air quality audit allows you to get a comprehensive, quantitative analysis of your air quality. Independent, licensed, third party professionals—usually industrial hygienists—perform this service by setting up monitors throughout your facility to collect and analyze air quality data. They can also attach monitors to workers’ uniforms to test exposure in the breathing zone. An air quality audit collects information on the volume of contaminants, toxicity and when and where air quality problems are occurring. An audit comes with a full report which can be a very useful tool in creating an air quality strategy—or in documenting the exceptional air quality you might already have!

If your air quality exceeds the PEL for any of the substances OSHA regulates, there are solutions. Increasing ventilation can cut contaminants and lower workers’ exposure levels. Adding ambient filtration would also achieve this goal while avoiding the high energy costs associated with ventilation’s need for heating or cooling your makeup air. If a more intensive solution is needed, a source capture system could be installed where the fumes or dust are generated. Source capture is the most efficient means of reducing exposure levels and meeting OSHA PEL’s. You can learn more about these options here.

The air quality experts at RoboVent understand how to meet any air quality goal in the most cost-effective way possible. They discuss with you the variables involved—airflow, filter media, targeted substances, equipment location and more—and prescribe solutions. They understand regulations and PEL’s as well as they do blower speeds and filter types.

What Is A PEL?

The Occupational Safety and Health Administration (OSHA) bases its air quality standards on “permissible exposure limits,” or PEL’s. A PEL is a maximum amount of substance in the air that a worker can be exposed to over the course of an eight-hour shift. The exposure is measured as a time-weighted average (TWA). If an exposure goes over the PEL, penalties can ensue.

Adhering to PELs is important for many reasons. First, workers’ health depends on it. PEL’s are set based on evidence of health effects, and they represent the maximum safe exposure. In fact, OSHA has said that many of today’s PEL’s might be outdated. Many of OSHA’s PEL’s were set in the early days of the agency, and it is possible that stricter limits are needed to adequately protect workers. The agency advises that employers err on the side of caution when setting air quality goals. Here are PEL’s for some common industrial contaminants:

- Cadmium: 0.005 mg/m3

- Hexavalent chromium: 0.005 mg/m3

- Lead: 0.05 mg/m3

- Nickel: 1.0 mg/m3

- Manganese: 5.0 mg/m3

How Are OSHA Regulations Enforced?

OSHA oversees roughly seven million workplaces in the U.S., so the agency must prioritize when it conducts inspections. “Imminent danger situations” and cases of severe injuries and illnesses are the first priority. Next are cases resulting from worker complaints and referrals. Next, targeted inspections look at high-hazard industries and individual workplaces that have a record of noncompliance. Lastly, follow-up inspections are sometimes done to check on abatement.

Inspections are done without advance notice but according to a published, standard procedure. They begin with a presentation of credentials and a conference with the employer. The walkaround is conducted with a representative of the employer as well as an authorized representative of employees, if requested. The compliance officer can also talk to employees in private during the inspection.

Inspections end with a closing conference to discuss findings. If there are violations, employers can discuss possible courses of action as well as ways to contest any citations and penalties.

OSHA enforces many different rules regarding workplace safety, not just air quality standards. Its compliance officers are trained to examine all of these areas, and employers can expect inspections to address all of them. Still, violations of air quality regulations are the fourth most common citation, after fall protection, hazard communication, and scaffolding problems.

Citations can lead to serious fines. As of January 2017, fines are $12,675 per violation, which can add up if there are multiple offenses. Companies showing a “willful or repeated” pattern could be fined $126,749 per violation.

OSHA provides assistance in navigating the enforcement process. Their compliance specialists are available in most of their area offices. Appeals can be made up to 15 work days after receiving a citation. OSHA maintains that their priority is maintaining safe workplaces and not pursuing citations.

What Are The Consequences Of Not Meeting OSHA Regulations?

Failure to comply with OSHA regulations can lead to serious fines and legal problems. OSHA has a standard procedure for discovering violations and for treating violators.

If an OSHA inspector finds a violation, the agency issues a citation and proposes a penalty. The citation must be specific and detailed, and the proposed penalty will have a deadline. Along with a penalty comes a list of actions a violator must take to correct the situation. Penalties are scaled to the severity of the violation, which are labeled in different categories: “willful, serious, other-than-serious, de minimis (trivial), failure to abate, and repeated.”

As of January 2017, most fines are $12,675 per violation. A company failing to correct a problem could also be fined $12,675 per day. Companies showing a “willful or repeated” pattern could be fined $126,749 per violation. These are obviously nontrivial amounts.

To help companies navigate the enforcement policies of OSHA, the agency provides compliance assistance specialists in most of its area offices. These can be found here.

Companies have the chance to appeal any citations. These appeals are made to the OSHA Area Director and can address the citation, penalty, abatement dates or other details. Companies have 15 working days after receiving a citation to file an appeal.

Source:

general info: https://www.osha.gov/OshDoc/data_General_Facts/factsheet-inspections.pdf

fines: https://www.osha.gov/penalties/

Health & Safety

What Particulate Level Do We Need To Target To Comply With ACGIH’s New Manganese Exposure Limit?

When the American Conference of Governmental Industrial Hygienists (ACGIH) recently lowered its recommended manganese exposure limit, it made waves in the welding world. While ACGIH limits don’t have the power of law, manufacturers pay attention. The ACGIH lowered its limit from 0.2 mg/m3 to 0.02 mg/m3, a tenfold decrease. The new limit is now much lower than OSHA’s current regulation—to be precise, it is now 250 times lower than OSHA’s limit of 5.0 mg/m3.

Fortunately, solutions exist to mitigate weld fumes that contain manganese. Source capture fume collectors can grab fumes before they affect workers and filter the toxic substance out of the air. Implementing solutions like this ensures workers’ health while also making sure you comply with air quality regulations.

Why Is It Hard To Breathe In The Plant After We’ve Been Plasma Cutting Even Though The Air Is Clear And No Smoke Is Escaping The Table?

Plasma cutting produces dust with extremely small particulates. This dust—though it is lingering in the air—might be invisible. The particulates are small due to the high degree of heat used in the cutting process.

Plasma cutting dust includes a number of contaminants that might be dangerous, and OSHA regulates workers’ exposure to many of these contaminants. If you aren’t sure what is floating in your air, consider doing an air quality audit. An audit will produce a comprehensive report that will tell you what is in your air and in what quantity. Using this information, you can develop a strategy for mitigating those contaminants. Most likely, a dust collection system will be required to capture the air coming off of a plasma cutting table. This will ensure that your workers are protected and that you are complying with air quality regulations.

If I Identify A Health Problem Related To Air Quality, What Steps Do I Take To Fix It?

After addressing any immediate concerns—such as seeking medical care for anyone who needs it, adding temporary ventilation or shutting down a process that is dangerous—you can start looking for the possible causes of your air quality problem. If you haven’t done an air quality audit recently, one is recommended. These audits are performed by licensed professionals who monitor your air, collect samples, analyze the data and produce a comprehensive report on your air quality. They will be able to tell you exactly what is in your air and in what quantities.

There are many good reasons to have an air quality report on file. The most significant one is the improved ability to protect your workers. It is also useful in meeting air quality regulations. The Occupational Safety and Health Administration (OSHA) issues exposure limits for many specific substances, and only by knowing what is in your air can you be sure you are complying with these regulations.

OSHA offers employers help in meeting these regulations. Their Compliance Assistance Specialists can identify ways a facility is falling short and can advise on ways to bring it into compliance. If a company gets an OSHA on-site consultation, it cannot result in penalties or citations.

Many options exist to remedy air quality problems. Increasing ventilation can reduce workers’ exposure to contaminants. If the volume of contaminants is high or if those substances are toxic, a more intensive solution would likely be required. A dust or fume collector that filters the air would protect workers throughout a facility and would also ensure regulatory compliance. High-volume applications like robotic welding cells would call for a source capture unit, which grabs the weld fumes at the source. Applications where the contaminants are less toxic could possibly be addressed by ambient capture equipment. These dust collectors circulate the air in a facility and filter out the contaminants, making sure everyone in the facility is protected.

What Is The Connection Between Indoor Air Quality And Workplace Safety?

Poor air quality can cause problems beyond inhalation risks. One of the greatest of these risks comes when oil mists are created in your facility. These mists can accumulate on surfaces and cause slip-and-fall hazards. Fortunately, specially designed dust collectors fitted with the right kind of filters can pull oil mists out of the air and prevent this problem.

Another major risk is that of explosions caused by combustible dust. When this dust combines with oxygen in a certain proportion, a single spark can cause it to explode. Even dusts that seem benign—such as wood dust or wheat flour—can lead to huge explosions in these conditions. Exhausting or filtering these dusts is crucial for ensuring that they don’t accumulate in the air or on surfaces in a facility. Spark arrestance and other fire protection measures in the dust collectors make sure sparks don’t develop within the equipment or ductwork.

Why Can’t Our Workers Just Wear Personal Protective Equipment To Meet Regulations?

This equipment should be a last resort. Masks may seem attractive, at first, given that they offer the impression of protection and seem cheaper than a comprehensive filtration system. However, they have many significant drawbacks, including:

- Masks often fit poorly, especially over facial hair. A poorly fitting mask might not keep out dangerous particulates.

- Units are cumbersome and uncomfortable. A common sight is workers pulling off their masks as soon as their task is complete, regardless of the air quality around them.

- Powered units need batteries that must be charged frequently.

- When personal protective equipment is the only air quality remedy being used, other workers not wearing masks in the facility will be exposed. Even small amounts of certain particulates can cause serious health problems.

- When masks are the only remedy to air quality problems, regulatory compliance will likely be in danger.

- In these facilities, the air quality will be visibly poor, creating an image problem for visitors, customers and new recruits.

- Untreated air can also damage equipment, as dust and grime accumulates on surfaces and in machinery.

- Personal protective equipment is expensive, in the long run. While the initial investment may seem modest, there are long-term costs that are unavoidable. In particular, disposable filters must be replaced frequently—a cost that adds up quickly.

Do You Have Equipment That Tells Me How Dirty My Air is Right Now?

Yes. RoboVent’s eQ™: Air Quality Monitoring System analyzes your air in real time. If contaminants reach a certain threshold, the system can turn air filtration equipment on. Once the air is cleaned, the system can turn the equipment off, ensuring that the equipment only runs when needed. This results in serious energy savings.

Being able to monitor your air quality in real time yields other benefits, as well. Improved air quality means boosts in employee moral and performance. Factory equipment lasts longer, since you can avoid the accumulation of dust and grime—things that can damage equipment. The filter life of your dust collectors is longer, as well.

How Do I Know What Harmful Chemicals Are In My Smoke?

The chemicals in your smoke depend on the process that produces them. For example, the chemicals in weld smoke are determined by the nature of the weld wire, what style of welding is being used, the gases being used, the material being welded and any possible residue on that material.

Certain materials are notorious for producing harmful chemicals when cut or welded. For example, welding stainless steel produces particulates of hexavelent chromium, a carcinogenic substance highly regulated by the Occupational Safety and Health Administration (OSHA).

Unfortunately, you can’t look at your air and know for sure which contaminants are present in it. Manufacturers should conduct an air quality audit to understand what substances are in their air. These audits are performed by licensed, third-party professionals who set up equipment to monitor air quality. After collecting samples, they analyze the data and produce a comprehensive report on the volume and nature of contaminants in your air.

Air quality engineers can help you address any air quality problems you might have. They will understand which contaminants have special regulations that demand attention. They can design and implement an air filtration solution that addresses those contaminants, as well as general air quality.

The Importance Of Moisture Containment/Removal In Compressed Air

How to Remove Moisture from Compressed Air

Moisture in the air will find its way into a compressed air system, and this can cause problems because air needs to be dry for an efficient system to function properly. Finding a solution to these kinds of issues is not always easy, because compressed air has multiple application functions and compressor designs.

If we see moisture in your compressed air lines during a service visit, we will bring this to your attention so your plant can address the issue with the compressed air supplier. Having moisture present in the lines can create havoc for filter pulsing systems as it may deliver moisture into the filter cabinet. Any water or oil in the lines will be pulsed onto the filters which drastically reduces filter life, essentially ruining the filter media and efficacy.

Clean, dry, compressed air is required to ensure a dust collection system runs properly.

The device used to remove moisture in your pressurized air system may be a simple drain valve. Some systems might have far more complicated multi-stage air drying systems.

The type of air compressor that you are using will ultimately determine the best way to remove moisture. While some systems may be able to handle lower moisture content and do not require additional drying needs, many other systems are going to need air dried and moisture released in some form or another.

Drain Your Air Compressor Tank

The mixture of oil and water that collects at the bottom of your air compressor is usually released through the valve found at the bottom. You want to drain the air compressor after every use not only to keep moisture out but also to prevent rust or other damaging elements from amassing in the compressor system.

You can easily modify your drain to make it more easily accessible or automatic. Consider some basic pipe fittings and a ball valve, which can make draining your tank a simple matter of just turning the ball valve a quarter turn. Timed solenoid or automatic no-loss drains can also be valuable items put into the system (for tanks, filter housings, dryers, etc.).

Water Traps

To dry compressed air, the air needs enough time and surface area in the tank to cool such that the water vapor can condense into liquid water that needs to be trapped. Water traps are more common in applications requiring extremely dry air.

Water traps will work with filter regulators such that incoming cool air enters and circulates. Water will collect at the bottom of the trap and drain out while the air exits through a filter element.

Removing Moisture from Compressed Air through Dryers

Filters and separators cannot remove water vapor. They can only remove liquid moisture droplets from the compressed air system.

If you want to remove water vapor, then you will have to use a dryer. Because colder air holds less water, multiple systems are used to cool compressed air and allow water to drop out of the air to be collected and drained.

Refrigerated air dryers are one of the best ways to remove moisture from compressed air through a single unit drying system, but they can be very costly if sized incorrectly.

Your refrigerated air dryer will function much the same as an air conditioning unit. The dryer will be connected to the air compressor and cool the air to a specific temperature. Air is usually cooled to between 35˚F and 50˚F. As a result, the pressure dew point (PDP) should be 33˚F to 39˚F.

Air will be heated and sent through lines for end use after water drops out of the air and is separated. If an application requires a lower PDP, then a desiccant air dryer could be required as condensate freezes at 32˚F. A desiccant air dryer system can purify compressed air and provide air purification from -40°F PDP down to -100°F PDP.

Types of Desiccant Air Dryers

There are essentially four kinds of desiccant air dryers:

- QMOD Heatless Modular Desiccant Dryer — The QMOD is a modular heatless desiccant dryer engineered for optimum space and performance that delivers a -40˚F instrument quality or -100˚F process air for system demands. Its compact footprint saves floor space, so it fits anywhere. It can be installed in either a vertical or horizontal position, NPT connections allow for easy installation and service access, and floor mounting brackets provide stability.

- QHD Heatless Desiccant Dryer — QHD heatless desiccant dryers are designed to provide optimal performance and efficiency in a variety of applications, using a small portion of compressed air to purge and regenerate the off-line tower. The QHD series includes 13 models that deliver between 230 and 3,400 cubic feet per minute (CFM) of clean, dry air.

- QBP Blower Purge Desiccant Dryer — Quality desiccant delivers consistent performance even in harsh conditions, and stainless-steel butterfly valves with actuators ensure a long lifetime. The standard filter package comes with two pre filters and an after filter, while NPT connections allow for easy installation and service access. There are also forklift slots on the frame for easy handling, and wide vessels allow for low airspeeds and longer contact times.

- QHP Heated Purge Desiccant Dryer — An industrial duty heated purge desiccant air dryer capable of removing moisture from compressed air through the process of Heat Assisted Pressure Swing Adsorption, in which saturated compressed air is directed over a bed of desiccant. Moisture adheres to the surface of the desiccant as the saturated compressed air flows up through it and is removed through an exhaust muffler during the regenerating cycle. The dryers are more energy efficient than heatless dryers.

Air Drying Through Piping Systems

Moisture can also be removed from compressed air through the way you plumb your air lines. For example, you can cool air by using longer metal piping lengths in an up and down pattern that allows air to be cooled while the pipes absorb the heat. When this occurs, the water will drop to the bottom of the piping system, possibly into a water trap.

When the air moves through piping in an up and down pattern, the amount of moisture released decreases along the journey such that each leg will have less water than the one before it. When properly constructed, there will be no water left in the final leg. Such methods are one of the cheapest ways to dry compressed air but can be easier said than done, consult further with your local specialist.

Things to Think About When Purchasing a Compressed Air Dryer

You need to take a variety of factors into consideration when determining the best kind of air dryer for your compressed air needs. Know your dew point requirement, the utilities available to you, the type of compressor being used and your ambient air temperature.

You will also want to know your operating pressure, inlet air temperature, and airflow. Some air dryers can be eliminated based only on the water that needs to be removed for an air compressor, and the dew point will generally be the first thing you consider.

The ranges that indicate the best type of dryer for specific dew points are typically deliquescent air dryers for 0˚- 80˚ F, refrigerated air dryers for 0˚- 32˚ F, desiccant air dryers with a silica desiccant for 0˚ - 40˚ F, and desiccant air dryers with activated alumina desiccant for 0˚ - 100˚ F. It is also important to think about the capacity (or CFM rating) and pressure (PSIG) of an air compressor.

Your purchase price is only a partial cost consideration, as you must also keep in mind the cost of energy use as well as maintenance costs. Additionally, there is the cost of the pressure drop that will occur as your compressed air travels through another system. To compensate for the loss of pressure through piping, you will have to run the compressor at a slightly higher pressure with an air dryer (or a second compressor system) to achieve the same pressure for end use.

When you are struggling to drain a tank or properly install a dryer system, do not hesitate to contact RoboVent. We can review your system and determine the best possible solutions to help get you functioning properly.

RoboVent is ready to talk your compressed air needs with you. Call (888) 298-4214 or contact us online right now to let us help.

Fire Safety

What Are My Options For A Fire Suppression System In My Dust Collector?

Without an effective fire suppression system, a dust collector could become a meeting point for the three components of any fire: a fuel source, oxygen and an ignition source. Fortunately, effective systems exist to protect both workers and equipment.

The best fire suppression system is an internal one, rather than simply relying on a facility’s sprinklers and fire extinguishers. The latter create a lot of mess and do little to prevent damage to a dust collector itself. Integrated fire suppression devices protect equipment, workers and production lines much more effectively than other measures.

A fire suppression system is able to dispense clean agent gas or other agents to kill a fire quickly and cleanly. This should be a last resort, however. A well-designed system will be able to use other fire-fighting measures before deploying gas.

RoboVent's Clean Agent Gas Fire Suppression is a dual-stage system that is activated by heat. Sensors within the Clean Agent Gas Fire Suppression can detect these factors and trigger a damper to shut off airflow to the dangerous areas. The system can also automatically turn off the blower. These actions cut off the flow of oxygen and kill a fire before it spreads. The clean agent gas is only deployed if needed.

What Is A Spark Arrestor?

A spark arrestor is a device that kills sparks before they can cause problems in a dust collector or other piece of equipment. Sparks are a common cause of fires in ductwork and dust collectors—providing one of the three necessary components of a fire: a fuel source, oxygen and an ignition source. If sparks are not stopped, they can ignite dusty filters or dust that is present in ductwork.

Sparks are a common feature of welding, grinding and metal cutting, so it is imperative that an active approach is taken to stopping them. A spark arrestor, such as RoboVent’s Delta3™ Spark Arrestor, catches and kills sparks before they can hit a filter. The Delta3™ does this by using centrifugal force to fling sparks and embers against the outer wall of the device, pulling of their thermal envelop so that they are rapidly cooled and extinguished. Testing has shown that this device kills 99.9% of sparks.

Using a spark arrestor can prevent catastrophic fires that might start in your dust collector and spread throughout your facility, as well as smaller fires that might put your dust collector out of commission for a day or two. These fires could shut down production lines that depend on the dust collectors. Cleaning up after fires is also a major burden for maintenance staff. A spark arrestor can avoid these problems, ensuring worker safety and saving money.

How Do I Reduce The Risks Of A Dust Collector Fire?

There are several methods available to reduce the risk of a dust collector fire. Fire prevention and mitigation for dust collectors should include:

- Spark arrestance (if near spark-producing processes) to minimize ignition risks in the ductwork and dust collector filter chamber.

- Installation of a fire/smoke detector that will sound an alarm and stop the collector if a fire is detected in the collector. This may be combined with a damper system to shut off airflow to the collector.

- A fire suppression/extinguishing system. This may be a water-based sprinkler system, a carbon dioxide gas (CO2) system, or a clean agent gas system such as RoboVent’s Supprex-200 system.

Spark arrestance is one of the best ways to lessen the risk of a dust collector. These systems prevent sparks from reaching the filter chamber to ignite a thermal event. There are three basic approaches to spark control for dust collection systems:

- Metal mesh or baffle systems that mechanically block sparks from entering the ductwork or dust collector intake.

- Centrifugal spark arrestance systems, which use centrifugal force to strip the thermal envelope from sparks.

- Detect-and-suppress systems, which use a sensor that activates a water- or chemical-based suppression system.

Detect-and-suppress systems provide near 100% spark reduction, but are very expensive to install, operate and maintain. Water or chemicals used to extinguish sparks may also interfere with production processes. They are typically used for explosive environments and other high-risk applications.

Mesh and baffle systems stop a majority of sparks, but not all. In addition, metal mesh spark traps require frequent cleaning to maintain efficient airflow and avoid the risk of a fire caused by buildup of flammable material on the screens.

A centrifugal spark arrestor, like the Delta3 Inline spark arrestor, is an excellent choice for most applications that produce a significant number of sparks. Sparks are extinguished by the centrifugal action, which forces burning embers against the walls of the device. When high airflow is maintained, most debris is cleaned out of the system, minimizing maintenance. In head-to-head tests against industry leaders, Delta3 Inline allowed zero sparks through at all tested airspeeds and had the lowest pressure drop.

How Does A Dust Collector Fire Start?

The causes of dust collector fires are summarized nicely by the “fire triangle.” This graphic includes the three primary components of a fire: a fuel source, oxygen and heat.

Unfortunately, a dust collector brings two of these elements together very efficiently: fuel and oxygen. Many dusts and fumes found in manufacturing facilities are combustible. If air quality is being properly controlled, these substances are likely being pulled into dust collectors. This, along with the filter media itself, is the fuel. A steady airflow through the dust collector ensures that oxygen is always present, as well. All that is left to produce a fire is a heat or ignition source.

Ignition sources are usually not hard to find in manufacturing facilities. Processes such as welding, grinding and metal cutting produce a steady stream of sparks, any one of which could start a fire. If these sparks are not extinguished before they hit the filter media, a fire could result.

Combustible Dusts and Explosion Safety

What Are The Steps To Prevention?

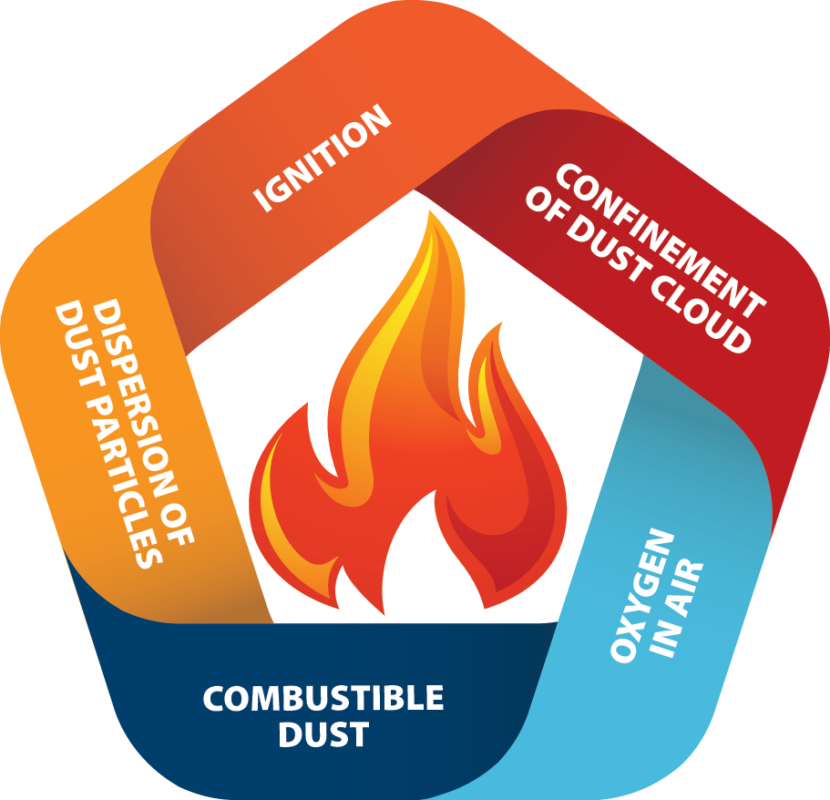

Explosion prevention begins when one piece of the Dust Explosion Pentagon is removed.

Remove Combustible Dust

If you can go without storing combustible dust in your facility, you don’t have a dust explosion hazard. This approach is safer than any other prevention technique because the fuel is no longer present.

Concentration Reduction

Keeping fuel below the minimum explosive concentration, or MEC, can be done through regular cleaning of your present equipment or selecting new equipment that doesn’t allow dust to accumulate inside it or in the ductwork.

Oxidizer Reduction

Oxidizer reduction is inerting the atmosphere to bring the oxygen level down below the limiting oxygen concentration, or LOC. This method involves the injection of an inerting gas like nitrogen into a closed system.

Spark Detection and Control

With this active system, possible ignition sources are detected. Examples include hot screws, smoldering piles, or a hot ember that has been sucked into a dust collection system. These hazards can be detected through the presence of smoke, radiation and high temperatures, and must activate a control method such as:

- an abort gate that shunts a hot ember out of the processing line;

- a suppression system that quenches it before it can get downstream and start the incipient stages of a flash fire or explosion.

Proper Hot Work Systems

Hot work such as welding and cutting should not be done in a dusty environment or on tanks or hoppers containing combustible dust. Clean up the material or empty it from the equipment being worked on before hot work begins.

Avoid Self-Ignition

Self-ignition can happen in silos where smoldering combustion is deep inside the stored material and turns into flaming combustion when it reaches the surface. This event can ignite a dust or gas explosion in the headspace.

Self-ignition can also occur in equipment like spray dryers. Material sticks to the inside edge, heats up and becomes an ignition source for a dust explosion. It is critical to remove this material safely; striking the vessel to dislodge the buildup could ignite an explosion.

Ignition Source Control

Minimum Ignition Energy, or MIE, is the minimum amount of energy required to initiate the combustion of a cloud of dust, vapor or gas. The lower the number, the more hazardous it is. Making sure the ignition sources in your system or surface temperatures are below the MIE of the dust cloud removes the ignition piece of the Dust Explosion Pentagon and is the final way to prevent an explosion from occurring.

Explosion mitigation - protecting workers, equipment or the environment from an incident or incident sequence – begins after the incipient stages have already begun.

Containment

Containment refers to increasing the confinement. Explosion-proof pressure vessels on a dust collector can avoid the need for an isolation channel between them. In other cases, such as hammer mills, the equipment is built strong enough to withstand an explosion inside.

Venting

Venting is a passive approach. The explosion vent is designed to open at a set pressure. When an explosion reaches the set pressure, the vent opens and the pressure is expelled into the surrounding area.

Flameless Venting

Flameless venting usually involves a passive explosion vent panel and flame-inhibiting device located within equipment such a dust collector. As an explosion begins, the explosion vent panel opens, permitting flame and dust to enter the flame-inhibiting device, reducing the flame’s temperature below the dust’s ignition temperature and thereby keeping the flame from spreading and causing an explosion.

Suppression Systems

Suppression systems actively monitor for the beginning of an explosion. A pressure sensor detects an incident at its incipient stage and activates a control system. This system could suppress the flame or inert the atmosphere so that the flame can’t develop further.

What Is The Dust Pentagon?

The 5 Elements of a Dust Explosion

There are five required elements for a dust explosion. They are sometimes referred to as the Dust Explosion Pentagon:

- A fuel, which is the combustible dust

- An oxidant, which is typically the oxygen in the air

- An ignition source capable of igniting materials when they are dispersed as a cloud

- Dispersion, which is when the accumulated dust is spread out and creates a dust cloud

- Confinement, which leads to pressure rise and a potential vessel rupture, facility obstruction or structural collapse

Deflagration

A term often used in connection with dust fires and explosions is ‘deflagration’ and is defined as combustion which propagates through a gas or across the surface of an explosive at subsonic speeds, driven by the transfer of heat. The term is used for both flash fires and explosions. With a dispersed dust cloud, deflagration can cause an unconfined flash fire or, when confined, an explosion that ruptures the containment vessel.

The Two Explosions

Combustible dust explosions often involve two explosions: primary and secondary. The primary explosion is the first to occur when dust suspension in a confined space is ignited and explodes. The first explosion will dislodge other dust that has accumulated which, when airborne, also ignites. A secondary dust explosion is often more destructive than the primary one.

How Are OSHA and NFPA Standards For Combustible Dusts Different?

The Occupational Safety and Health Administration (OSHA) sets federal standards for workplace safety and has developed regulations that apply to dust explosions. These include standards addressing issues such as materials handling, as well as other safety issues, such as emergency exits. Failure to comply with OSHA regulations could carry serious fines.

Standards set by the National Fire Protection Association (NFPA), on the other hand, are guidelines published by scientists and other leading experts in the field of fire safety. The organization’s primary list, “Standard on the Fundamentals of Combustible Dust,” constitutes the most advanced recommendations to protect workers and facilities that encounter combustible dust. NFPA recommendations don’t carry any weight of law, but they are highly respected and are often looked to for guidance when making federal and state regulations.

How Does NFPA 484 Relate To 3D Printing?

Many metal powders are used as raw materials in 3D printing. These metal powders can be highly combustible, and the 3D printing process generates dust. NFPA 484 begins to outline proper handling and processing of this combustible dust and metal powders used in additive manufacturing.

What Is NFPA Standard 652?

NFPA 652, Standard addresses the fundamentals of Combustible Dust to mitigate fire, flash fire, and explosion hazards. This new standard provides the basic principles and requirements for identifying and managing the fire and explosion hazards of combustible dusts and particulate solids. This standard serves a wide variety of industries including chemical, wood processing, metals, and agricultural.

Does NFPA 484 Allow For The Use Of Downdraft Benches?

Yes, NFPA 484 permits the use of downdraft benches and environmental control booths as long as it collects less than .5 lbs of dust is collected and emptied each day, and a DHA (Dust Hazard Analysis) has been conducted.

What Are The Combustible Metals?

Aluminum, magnesium, titanium, zirconium, sodium, lithium and potassium have the potential to combust when in powder or dust form.

What Are Legacy Metals?

According to NFPA 484, Legacy Metals include aluminum, magnesium, niobium, tantalum, titanium, zirconium and hafnium.

What Are Nanometals?

Nanometals are very fine metallic particles smaller than 500 nanometers.

How Do You Reduce The Risk Of Static Electricity Around Combustible Dust?

To reduce the accumulation of static electrical charge, be sure all components of your dust collection system are properly bonded and grounded

What Are The Components Of A Dust Hazard Analysis (DHA)?

DHA is a systematic review to identify and evaluate the potential for fire, flash fire and explosion hazards associated with the presence of one or more combustible particulate solids arising from your processes or present in your facilities.

There are five critical elements to a thorough Dust Hazard Analysis:

- Methodology and scope

- Material characterization

- Process characterization

- Hazard analysis and recommendations

- Administrative controls and recommendations

For more information around each component, link to DHA White Paper here.

What Is NFPA 484?

The NFPA 484 Standard addresses the proper handling of combustible metal dusts to reduce the risk of explosion. This standard applies to all facilities that process or finish potentially combustible metals, creating metal dust or powder.

What Is Combustible Dust?

The National Fire Protection Agency (NFPA) defines combustible dust as “any finely divided solid material that is 420 microns or smaller in diameter and presents a fire or explosion hazard when dispersed and ignited in air.” Any combustible material can burn rapidly when in a finely divided form. If such a dust is suspended in air in the right concentration, under certain conditions, it can become explosible. Left uncontrolled, dusts may migrate from the point of production/release, increasing the portion of the facility subjected to combustible dust fire and explosion hazards. Even materials that do not burn in larger pieces, given the proper conditions, can be explosible in dust form. Typical metalworking materials that can form combustible dusts include titanium, aluminum, magnesium and iron. The amount of dust required to produce a dangerous dust cloud can be surprisingly small — a dust layer as little as 1/32 inch thick can be of concern in some situations.

How Can I Prevent A Dust Explosion?

The first step in preventing a dust explosion is understanding the nature of your dust. Having your dust professionally tested will allow you to properly address the dangers, if any exist. A professional analysis of your dust will provide you with the dust’s Pmax and Kst values, figures that will tell you how potentially explosive the dust is.

If your dust is combustible, a full Process Hazard Analysis is advised. This analysis looks at how your dust is produced and how it propagates throughout your facility. Next, a list of recommendations will address ways to mitigate the dangers. These might include:

- Altering the process so that dust particulates are coarser and less explosive

- Adding screens or walls to limit the spread of dust or the spread of an explosion

- Identifying and reducing possible sources of ignition

Actively filtering your air is another effective way to prevent a dust explosion. This practice prevents dust from reaching concentration levels necessary to produce an explosion. Many kinds of dust collectors are available, including both source capture and ambient capture units. A source capture unit collects dust close to the source or application. This is the most effective way to prevent dust from getting in the air. Ambient capture equipment filters the air throughout the entire facility, preventing an accumulation of dust in the air or on surfaces.

For more information on preventing dust explosions, check out OSHA’s manual: Combustible Dust in Industry: Preventing and Mitigating the Effects of Fire and Explosions.

How Can Air Quality Problems Lead To A Dust Explosion?

The biggest air quality problem that could lead to a fire is the accumulation of dust in the air or on surfaces in a facility. When combustible dust combines with oxygen in the right proportion in an enclosed space, a dust explosion is possible. Manufacturers must be careful to keep dust concentrations at low enough levels to avoid this possibility. A vigilant approach to dust collection can prevent fires and explosions while also protecting workers’ health.

The accumulation of dust on surfaces is another air quality issue that can worsen a dust explosion. During a dust explosion, often the initial blast stirs up dust that has settled throughout a facility, creating a new cloud of combustible material that ignites and causes a massive secondary explosion. Again, using dust collectors avoids this air quality problem.

What Regulations Apply To Combustible Dusts?

The Occupational Safety and Health Administration (OSHA) enforces standards for workplace safety, and the agency has developed a list of standards that apply to dust explosions. Some of these standards apply to workplace practices, such as materials handling, while others address typical safety issues, such as emergency exits. It is a manufacturer’s responsibility to comply with these standards and to reduce the risks of dust explosions. To meet these OSHA requirements, manufacturers must address their air quality. Most likely this will mean exhausting or filtering their air in order to reduce dust concentrations.

Another set of standards for manufacturers to look to for guidance is the National Fire Protection Association’s (NFPA) “Standard on the Fundamentals of Combustible Dust.” While these standards are not federal regulations and carry no weight of law, they represent the leading science on the risks and mitigation measures. If OSHA changes its regulations on these matters, the agency will likely look to the NFPA standards for guidance.

Manufacturers should indeed be aware of possible changes in OSHA regulations in the future. In 2009, OSHA began the process to develop a more comprehensive standard to regulate combustible dust. The regulatory process began with issuing an “advance notice of proposed rulemaking” and holding a series of stakeholder meetings. One of the next steps was to convene a panel required by the Small Business Regulatory Enforcement Fairness Act (SBREFA). The process will likely take a while, as is usually the case, but the eventual change could apply to a wide swath of manufacturers and could compel them to make serious changes to their air quality.

What Is A Dust Explosion?

Dust explosions occur when combustible dusts build up in the air and combust rapidly, causing a strong pressure wave to form. They are a deadly hazard in a variety of workplaces, from grain silos to plastics factories. A dust explosion requires several factors to be present at once. These include:

- A combustible dust at the right concentration level

- Oxygen

- An enclosed space

- An ignition source

Sometimes these factors are combined into a graphic known as the “Dust Explosion Pentagon.” The component in this graphic called “dispersion” is also known as concentration. If a concentration of dust is too low, there is not enough of it present to fuel an explosion. If the concentration is too high, there is not enough oxygen to support combustion.

While some combustible dusts are easy to guess—wood and paper dust, for example—others aren’t, such as aluminum dust. Combustible dusts become more dangerous as particulates become finer. These dusts feature a high ratio of surface area to volume, adding to their combustibility. When these dusts combine with oxygen within a range of concentrations, a dust explosion is possible.

In these conditions, all that is needed for an explosion is an ignition source. This source can be anything from a cigarette to a spark to an overheated wheel bearing. Under the right conditions, some combustible dusts can self-ignite as a result of static that builds up as particulates rub against one another. The ignition causes the dust to combust quickly—a process called deflagration that creates a wave of high air pressure. Sometimes this explosion can stir dust that has settled in the space, creating a cloud of new dust—a fuel source for an enormous secondary explosion. A dust explosion can blow out walls in a facility and kill or injure workers within the space or nearby.

How Do I Know If My Dust Is Combustible?

The combustibility of dust depends on a number of factors. For a quick check, look at this chart from the Occupational Safety and Health Administration (OSHA). If your dust is on that list, then you need to be concerned about combustible dust.

Just how combustible your dust is, however, depends on many things you won’t find on that list nor be able to see in your facility. For example, particle size has a major impact on the combustibility of a dust. In general, the smaller the particle, the more dangerous the dust.

To understand the specific dangers of your dust, it is best to have it tested by professionals. They can analyze a sample of your dust and produce a full report describing it. Their report would include two key numbers: the Pmax and Kst values. These numbers measure the explosive power of your airborne dust. The Pmax value is the maximum pressure that might be produced by an explosion of your dust. The Kst value—also called the deflagration index, measuring the relative severity of the explosion—is determined by several factors, including the size and chemical nature of your particulates, along with their moisture level.

Having at least a cursory understanding of these values is useful in assessing the risks. For example, the larger the Kst value, the stronger the possible explosion. A Kst value of 0 will result in no explosion. A value over 0 and below 200 could result in a “weak explosion.” A value between 200 and 300 could result in a “strong explosion.” These substances might include cellulose or wood flour. A value over 300 could see a “very strong explosion.” These materials might include aluminum or magnesium dust.

How Do I Test The KST (Kst) Factor Of My Dust?

Testing the KST factor of your combustible dust will likely require a professional service. These experts have equipment to ignite your dust in a controlled setting that allows for precise measurements to be made. This kind of test would produce both Kst and Pmax values. The Kst value measures the “relative explosion severity compared to other dusts,” as OSHA says. The Pmax value is the maximum pressure that might be produced by an explosion of your dust.

Dusts vary widely in their Kst values, even among the same substance. Factors such as particle size, particle shape and moisture content affect the Kst value. This is why it is essential to have your dust tested. Simply looking up your dust on a list of what is combustible and what is not is not adequate. Having your dust professionally tested will ensure that you understand the dangers.

System Design

What Is Source Capture Of Dust And Fumes?

Source capture describes dust and fume collection practices that are point solutions. They grab particulates at the source, preventing them from exposing workers, damaging equipment and threatening regulatory compliance. The alternative to source capture is ambient capture, a facility-wide solution to continually clean and turn over air from an entire facility. Source capture offers particular benefits, including the following:

- More efficient capture - Grabbing particulates at the source much less airflow than ambient capture. This results in lower energy use and, over time, major cost savings.

- Reduced exposure for workers - When harmful particulates are captured at the source, they don’t have a chance to threaten workers. Many particulates in dust and fumes are breathing hazards for workers, and exposure can lead to serious health effects, including death. Allowing those particulates to travel throughout a facility before capturing them is a health hazard.

- Improved regulatory compliance - Many substances found in dust and fumes are highly regulated by OSHA. For example, hexavalent chromium, a common byproduct of welding stainless steel, carries a very strict OSHA standard (2.5 micrograms per cubic meter of air). Capturing fumes like these at their source ensures that a manufacturer meets these standards.

What Is The Best Source Capture Solution For Manual Cutting And Grinding?

The best source capture solution in these cases would be a dust collector that provides powerful suction, easy maintenance and low energy use. The best solution depends on your particular operation. Here are the best options:

- For a single cutting or grinding station, a portable collector would work well. Units such as the VentBoss collectors go where you need them and offer most of the features of larger units, including compressed-air cleaning and built-in spark arrestance. Portable welding ventilation units can be attached to a wide range of fume arms, providing great flexibility.

- Backdraft or downdraft tables are also great source capture solutions for cutting or grinding operations. These tables provide a functional work surface and powerful suction that pulls dust away from the worker’s breathing zone. These tables can include their own filtration units, be connected to a portable collector or can be ducted into a larger collection system.

- Large dust collectors like RoboVent’s Senturion collector can provide efficient filtration for an entire facility. A powerful unit like this can be ducted to many different cutting or grinding stations.

No matter what solution you choose, it is vital to control dust and fumes in the workplace, especially if it involves metalworking. Many of these dusts are toxic and pose serious dangers to workers. What’s more, these dusts also carry specific regulations from the Occupational and Safety and Health Administration (OSHA). For example, metals like cadmium, nickel and aluminum have individual exposure limits, set by OSHA.

What Is The Best Dust Collector To Pair With A Fume Arm?

A fume arm is a versatile solution for dust and fume collection and can be attached to a variety of dust collectors including centralized systems, standalone units and portable systems.

Fume arms generally have one of two diameters: 6 inches or 8 inches. The 6-inch arm requires around 600-750 CFM (cubic feet per minute) of airflow, while the 8-inch arm requires 1,000-1,200 CFM.

Fume arms are often connected directly to portable dust collectors, creating powerful solutions such as RoboVent’s PowerBoom device. These systems effectively eliminate fumes at their source, protecting welders and workers throughout an entire facility. The best collectors can be configured to run only when an operation is running, limiting energy use and maintenance costs.

Fume arms can also be ducted to centralized dust collection systems.

The RoboVent Senturion series provides powerful filtration for centralized ducted systems.

Will A Centralized System Extract Dust And Fumes Equally From All Intake Points?

When designed properly, a centralized system will indeed collect fumes equally well from all of its intake points. Air quality engineers are experts in these matters and take many variables into consideration. These variables include:

- The size of each intake point and how close the intake points are to the collection unit.

- The number of intake points. More intake points will require more horsepower from the motor.

The gates on a duct system are like valves, and they should be sized according to how close they are to the source of suction (the dust collector)—closer gates will be smaller than ones farther away. Sizing gates in this way, an engineer will balance a system so that every dust- or fume-generating application gets the amount of suction it needs.

What Is The Capture Efficiency Of A Backdraft Or Sidedraft Table?

The capture efficiency of these units depends a lot on surrounding air current patterns. If the area is turbulent, it will cut into the capture rate. For example, if the backdraft table is next to a garage door that is often open, it won’t work perfectly. This turbulence will disturb the suction and could prevent some of the weld fumes from being captured.

On the other hand, a backdraft table that is well placed will perform with a high capture rate. A table that is enclosed in some way could be expected to capture 90-100% of weld fumes.

What Is The Capture Rate Of A Fume Arm?

Fume arms have a long history of effectively abating weld fumes in industrial operations. If a welder is working on a small piece in the same location, over and over, a fume arm, such as PowerBoom, can capture nearly 100% of weld fumes.

If pieces being welded are large, a different solution might be more appropriate. In this situation, a welder is constantly moving, and the fume arm must be continually repositioned. This step is often overlooked, leading to a major drop in capture efficiency. When a fume arm isn’t the right solution, a backdraft table might work, assuming the part fits on the table. When the situation calls for a highly flexible solution, a fume gun is the best way to capture fumes at the source.

Should I Use Individual Dust Collector Units Or A Centralized System To Collect Weld Fumes?

This answer hinges on two key details about your operation: how valuable is your floor space and what is your potential for growth? The size and layout of your operation might play a considerable role, as well. Let’s look at the benefits of both options.

Benefits of a centralized dust collection system:

- Optimizes floor space - If floor space is precious, then a centralized system located on the ceiling or outside is a great option. A powerful unit such as the RoboVent Senturion dust collector can capture dust and fumes from an extensive centralized system with many intake points.

- Lowers maintenance costs - Fewer service points, in centralized systems, lead to lower maintenance costs than an array of individual dust collection units.

- Creates efficiencies - Centralized systems also make it easier to monitor the network, track its performance and make adjustments where necessary. Over time, this data collection, as well as the chance to use more automated controls, can generate major cost savings.

- Provides flexibility - If you might be changing your layout or expanding your production in the near future, a centralized system would better suit your needs. A well-designed centralized system could hold capacity for many welding stations, and adding these stations would be much easier than if they had to be paired with new individual dust collectors, as well. For example, RoboVent’s Grid Configuration uses modular, standardized ductwork that can be reconfigured easily as your needs change.

Benefits of using individual dust collection systems:

- Saves money in certain situations - Welding operations that use only a few stations might be able to collect their fumes quickly and efficiently using standalone collectors. Such an arrangement would avoid the need for ductwork and avoid higher installation costs.

- Avoids overkill - If your operation only produces a modest amount of weld fumes, individual dust collectors, such as RoboVent’s Spire units, could capture them effectively.

- Saves energy - Centralized systems need to move air throughout an entire facility, which uses a lot of power. If your facility only needs a few individual dust collectors, you could save money on energy.

- Allows for odd layouts - If your welding stations are few and far apart, a centralized system with lots of ductwork might not make sense. A few well-placed standalone dust collectors would work well in this situation.

- Provides options for transport - If your dust collectors might be moved to another facility, individual units are obviously the way to go.

I Need Another Collection Point For A New Weld Station. Can I Just Tap Into The Existing Duct Overhead?

In short, no. The existing ductwork and filtration system presumably have been sized for the current welding needs. To add a port and a new source of fumes would unbalance the system and compromise its integrity.

For example, adding a new port would cut airflow through all of the existing ports; this could affect capture rates. To add a new weld station to a system, an air quality engineer would have to run new calculations for the system and determine the power needed for the new arrangement.

Before adding a new collection point to your existing centralized source capture system, consult with an air quality system designer.

How Do I Know What Size Dust Collector I Need For My Source Capture System?

A source capture solution is sized according to many variables. Dust collector capacity is a function of several factors:

- CFM: The air speed required for a source capture system—measured in cubic feet per minute (CMF)—is calculated in the design of any system. Operations with a high CFM will need more powerful motors than those with a lower air speed. Too little CFM won’t carry the particulates all the way to the dust collector; too much could drive the particulates too deeply into the filter media, clogging it. Maintaining a high CFM also costs more, due to the increased energy use. Fortunately, air quality engineers understand how to balance these variables and calculate the right CFM for your needs.

- Filter media: Filter media, measured in square inches, is the second element in dust collector design. The ration of airflow to filter media is called the “air-to-cloth ratio.” It is important to make sure you have enough filter media for the volume of particulates you produce and the total volume of air you are moving. Using too little filter media results in significantly shorter filter life, greater maintenance burden and more wear and tear on equipment.

- Motor horsepower: Source capture systems with large particulates or high volumes of dust require more horsepower from the dust collector.

Dust collector sizing depends on several factors:

- Distance from the source to the dust collector - The longer the distance, the more horsepower you will likely need from your motor.

- Particulate type - Fine particles require much less power and air speed than large particles. A lower air speed, measured in cubic feet per minute (CFM), means that less power is required and that operating costs will be lower.

- Volume of particulates - Some operations produce a high volume of particulates, requiring a lot of filter media.

- Pipe or duct diameter - Large particulates require larger diameter pipes and ducts, but there are limits to how large a pipe should be. If it is too large, there is a risk of particulates dropping out of the airflow. If this happens, it becomes a maintenance burden and perhaps a fire hazard.

Obviously, many of these variables are interrelated. For example, particulate type, CFM and motor horsepower are all connected. Professional air quality engineers are able to factor all of these variables into their design for a source capture system.

What Is The Best Source Capture Solution For Robotic Welding?

The best way to capture weld fumes from a robotic welding station is to enclose it and attach the cell to a dust collector. This ensures that workers are protected and that weld fumes are caught at a very high capture rate. Enclosures are neither expensive nor difficult to install, but sometimes there are obstacles to implementing them, such as overhead cranes or other equipment. The best option is often a modular enclosure, such as RoboVent’s Streamline Hood. This hood can be customized to fit over any operation, including multiple robotic welding stations. It also features a low profile that works well with overhead equipment. Air quality engineers are able to advise on the most practical and cost effective way to enclose or partially enclose a welding cell.

RoboVent’s Spire dust collector is a good example of available units with powerful filtration and low running costs that can be attached to welding cells.

If an enclosure is not possible and if a welding arm produces a high volume of weld fumes, especially over a large weldment, the next best solution is to affix a hi-vac extraction system to the robotic arm. This system will capture fumes at the source. Because the robot performs the same task in the same way every time, air quality engineers can design a system that accounts for the robot’s speed and movements, ensuring that the fume extraction point is well placed at all times.

What Is The Best Source Capture Solution For Manual Welding?

The best source capture of weld fumes will attack the two main sources of fumes: those coming off the welding point and residual fumes coming off the hot weld seam. Not all fume capture solutions are able to catch both. However, a backdraft/sidedraft plenum excels at this challenge. For bench welding with large (but not huge) parts and consistent placement on the bench, this solution is able to pull the fumes away from the worker’s breathing zone and capture the fumes with near total efficiency.

Fume arms, another popular air quality solution, can be very effective, too. When the welding piece is small and always in the same location, a fume arm is a great solution. But if the piece is large, a fume arm must be repositioned frequently. Welders are often inconsistent in doing this, leaving many fumes not captured. Residual fumes are very hard to capture.

After backdraft tables and similar devices, the fume gun is another excellent source capture solution for weld fumes. When used correctly, RoboVent’s MIG fume gun can capture up to 95% of weld fumes at the source. These devices are especially useful in unconventional situations, such as welding on very large parts or in places where a welding bench isn’t available.

How Is A High-vacuum (hi-vac) System Different From A Low-pressure One?

Dust collection systems fall roughly into two categories:

- high volume/low pressure

- low volume/high pressure

High-volume, low-pressure systems are more common. These are likely what you think of when you picture a dust or fume collector. As a point of reference, they might move up to 10,000 CFM (cubic feet per minute) of air at 10-12 inches of vacuum pressure. Dust collectors used for ambient air filtration operate like this, turning over large amounts of air throughout the day. Source capture systems, including collectors attached to welding hoods like the RoboVent Spire, can use this method as well.