SOLUTIONS FOR THERMAL SPRAY DUST COLLECTION

RoboVent offers robust dust and fume control solutions for manufacturers using thermal spray processes. RoboVent Senturion is a rugged, high-powered dust collector that minimizes maintenance and operating costs for thermal spray dust collection. Senturion can be easily equipped with a spark arrestance system and deflagration system to mitigate combustion risks for explosive thermal spray dusts.

A RoboVent solutions engineer can design an effective dust control system for your thermal spray applications. We can help you evaluate the health and combustion risks of your thermal spray dust, determine the best dust collector and filter media for your application, and design a comprehensive air quality solution including dust containment and collection, ductwork design, and ventilation and makeup air.

Types of Thermal Spray Processes

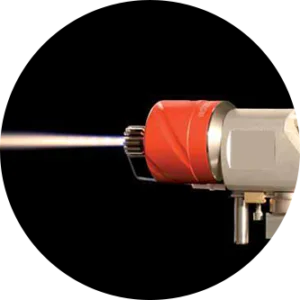

Thermal spraying refers to any process in which a material is heated or melted and then sprayed onto a surface. The feedstock (which may be a metal, alloy, plastic, ceramic or composite material) is heated or melted using electricity (plasma or arc) or combustion flame.

Health Risks of Thermal Spray Dust and Fumes

Combustion Risks of Thermal Sprays

Most of the dusts created by thermal spray processes are considered to be combustible dusts. That means they can explode when allowed to concentrate in the right levels in the presence of oxygen and an ignition source. Both metallic and non-metallic thermal spray dusts can be considered combustible in the right concentrations.

Regulations for Dust and Emission Control for Thermal Spray Processes

The Occupational Safety and Health Administration (OSHA) has issued specific regulations for many different metallic and non-metallic dusts. These are expressed as Permissible Exposure Limits (PELs), which are measured and averaged over a worker’s 8-hour shift. Manufacturers are responsible for ensuring that workers are not exposed to hazardous dusts in levels above the PELs. Failure to control dust in areas where workers may be exposed can result in serious fines and legal action.

Considerations in Dust and Emission Control for Thermal Spray Processes

Most thermal spray processes will be conducted within a spray booth or enclosed area. This allows thermal spray dust and fumes to be contained for efficient source capture. In a source capture solution, air is collected as close to the source as possible and filtered to remove contaminants. Because air collected from thermal spray processes may contain trace gases (from the heating process) as well as solid particulates, it is normally not returned to the facility, even when filtered.

RECOMMENDED SOLUTIONS

OTHER SOLUTIONS

TOTAL FILTRATION PARTNER

RoboVent is your full turnkey resource for clean air in industrial environments. From facility testing and engineering, to installing equipment, providing replacement filters and preventive maintenance, RoboVent is ready to manage the whole process.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.

Metallic thermal sprays generate some of the most hazardous dusts and fumes—similar to the fumes generated by welding metals. Metal alloys may contain a number of different toxic elements, each with their own health risks. These may include nickel, aluminum, copper, cadmium, cobalt, manganese, zinc and beryllium. Prolonged exposure to metallic fumes from thermal processes is linked to lung cancer, other respiratory problems such as chronic obstructive pulmonary disease (COPD) or acute pulmonary edema, kidney or liver disease, thyroid problems and nervous system disorders. Metallic thermal sprays may also cause contact dermatitis and eye irritation. Some metals, such as nickel, may cause severe allergic reactions in susceptible people.

Metallic thermal sprays generate some of the most hazardous dusts and fumes—similar to the fumes generated by welding metals. Metal alloys may contain a number of different toxic elements, each with their own health risks. These may include nickel, aluminum, copper, cadmium, cobalt, manganese, zinc and beryllium. Prolonged exposure to metallic fumes from thermal processes is linked to lung cancer, other respiratory problems such as chronic obstructive pulmonary disease (COPD) or acute pulmonary edema, kidney or liver disease, thyroid problems and nervous system disorders. Metallic thermal sprays may also cause contact dermatitis and eye irritation. Some metals, such as nickel, may cause severe allergic reactions in susceptible people. The flame or arc used to heat materials for thermal spraying acts as an ignition source, making it imperative that dust in the thermal spray room or booth is not allowed to accumulate in the air or on surfaces. Thermal spray dusts may also create a combustion risk inside the dust collector. Care must be taken to eliminate the risk of sparks inside the dust collector.

The flame or arc used to heat materials for thermal spraying acts as an ignition source, making it imperative that dust in the thermal spray room or booth is not allowed to accumulate in the air or on surfaces. Thermal spray dusts may also create a combustion risk inside the dust collector. Care must be taken to eliminate the risk of sparks inside the dust collector. These are PELs for some of the elements and compounds commonly found in dust from metallic thermal spray processes:

These are PELs for some of the elements and compounds commonly found in dust from metallic thermal spray processes: