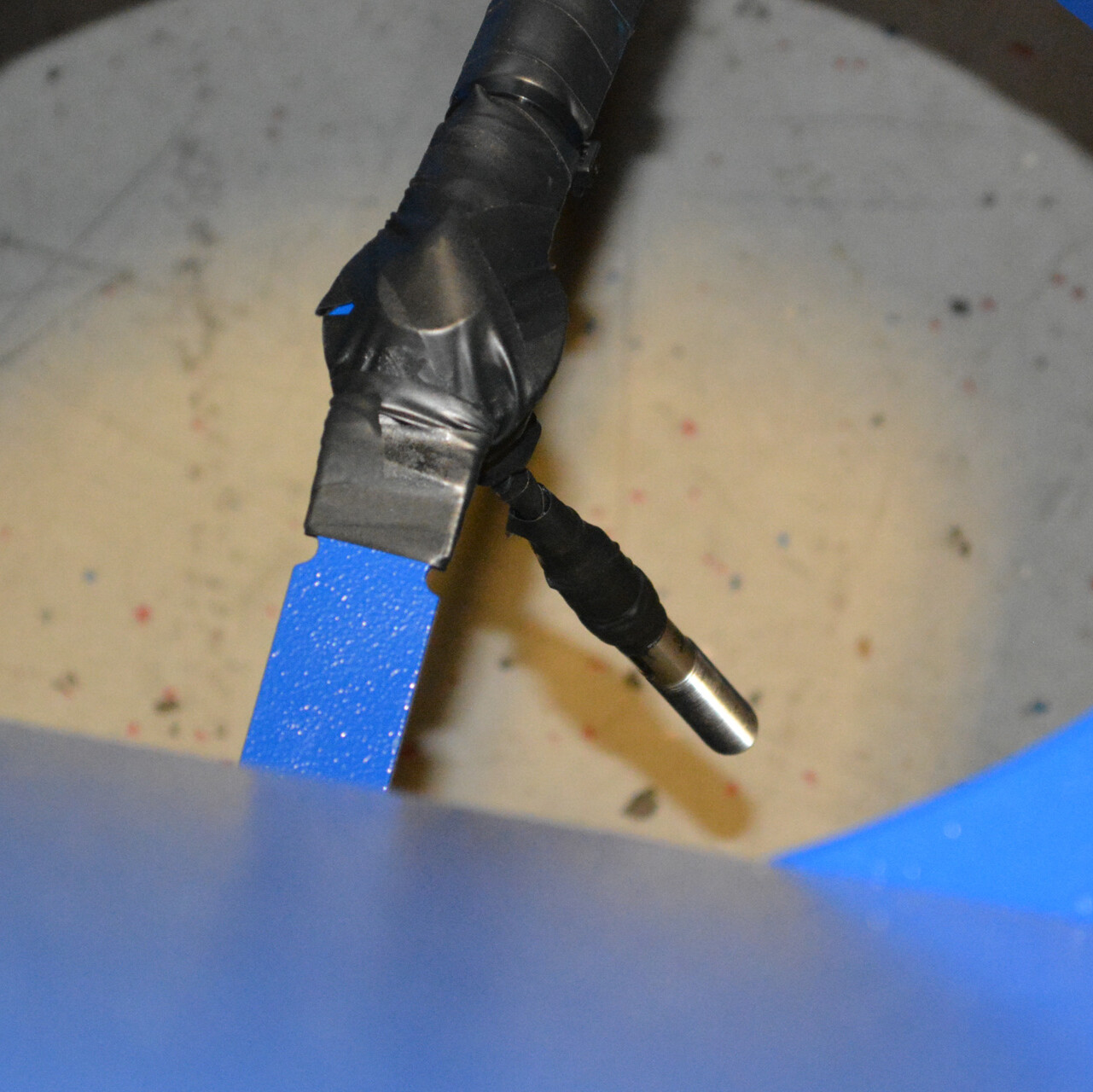

Barrel Level Sensor

A sensor which sits inside the containment barrel and monitors the dust level inside. A control panel alert warns the operator that the barrel needs to be emptied, simplifying maintenance.

Avoiding Overflows

As dust falls into your containment system, it can be hard to know whether the drum is full or not. The barrel level sensor answers this question for you. When the dust volume in your drum reaches a certain level, the sensor sends an alert to your control system, letting you know it's time to empty the drum.

The barrel level sensor eases the maintenance load on your staff. If the dust level gets too high in a drum, emptying it can create a huge mess. If neglected for too long, the dust can even build up within the dust collector. The sensor lets your workers focus on other things until the right time, so you can avoid dust overflows and maximize each dumping.