UNDERSTANDING AIR QUALITY OPTIONS

SOURCE CAPTURE VS. AMBIENT COLLECTION AND AIR FILTRATION VS. EXHAUST

What's the best way to clear the air in your facility? The right approach to indoor air quality (IAQ) depends on the applications you are using, the amount of dust or fumes generated, the specific health and safety risks of your particulate, and the layout and characteristics of your facility.

There are four basic approaches to indoor air quality for industrial facilities:

FILTRATION VS. EXHAUST

THE FIRST CHOICE YOU HAVE TO MAKE IS BETWEEN A FILTRATION SYSTEM AND AN EXHAUST SYSTEM.

In an exhaust system, contaminated air is simply captured and exhausted outside of the facility. This is generally done using a ventilation system with large fans that pull dirty air out and exhaust it to the outside, often through the roof. A make-up air unit is required to return clean outdoor air to the facility and avoid creating negative air pressure inside the building. In a filtration system, dirty air is pulled into a collector and through a series of filters. The filters remove particulate from the air. Clean air can then be returned to the facility.

A simple exhaust and make-up air ventilation system is the cheapest and easiest to install. If you only need ventilation to clear the air after occasional “dirty work,” this may be the right approach for you. Learn more about industrial ventilation and exhaust and make-up air systems: Industrial Air Filtration and Ventilation

However, if your industrial processes generate large amounts of dust and fumes on a regular and ongoing basis, filtration may be a better option. Filtration systems offer several advantages:

AMBIENT VS. SOURCE CAPTURE

The second major consideration is ambient vs. source capture.

- Ambient systems are centralized whole-facility solutions. They continually clean and turn over air from the entire building.

- Source capture systems are point solutions. They capture fumes and particulates at their source to prevent them from propagating throughout the facility.

The choice between source capture and ambient filtration depends on the type and volume of fumes you are producing as well as the physical constraints in your building. If you are generating significant volumes of dangerous fumes, such as from robotic welding, in most cases it is preferable to capture them as close to the source as possible. Source capture reduces the amount of fumes that workers will breath in both near the fume-generating process and throughout the facility as a whole. Hoods, fume arms, backdraft tables and fumes guns collect dangerous fumes and particulate as they are created.

However, source capture is not always possible. The size of parts being worked on and physical constraints such as overhead cranes may make source capture difficult to implement. In these cases, an ambient system combined with personal protective gear for workers closest to the fume-generating processes may be the best option. Ambient may also be a viable option for facilities that produce lower volumes of particulates throughout the facility rather than large volumes contained in specific areas.

SOURCE CAPTURE OPTIONS FOR INDUSTRIAL AIR FILTRATION

Source capture systems fall into several categories, each designed for different purposes. The correct solution will depend on the application (e.g., manual welding, robotic welding, cutting or grinding).

Overhead Hoods

Hoods are generally the best solution for robotic or laser welding applications. Welding fumes are contained within the overhead hood, keeping them out of the ambient air in the facility and making them easier to collect. Overhead hoods can be configured to contain one or more welding operations. Overhead hoods are sometimes also used with manual welding applications. However, they do not keep weld fumes out of the breathing zone for the welder, so they must be combined with another source capture system or personal protective equipment for the welders inside the hood.

Fume Guns

Fume guns are a two-in-one welding gun and fume capture device that extract the contaminants as soon as they are created. Because the extraction is occurring right at the welding arc, it is always positioned correctly for maximum extraction efficiency. Fume guns work well for welding applications where the welder is highly mobile and it is not practical to use a fume arm—for example, large pieces that require welders to crawl over the equipment or use lifts, or welding inside equipment such as tanks or ship hulls. Older fume guns tended to be bulky and reduce visibility for welders, so many welders have resisted using them. However, newer fume guns like the RoboVent Extractor are smaller and lighter so they are more comfortable to use and maintain good visibility of the weld seam.

Fume Arms

Fume arms are movable suction devices that are manually positioned over or near the weld arc. They are used for manual welding applications. Used correctly, they are highly efficient (roughly 95%) at capturing fumes in their immediate vicinity. Because they are so focused, they require relatively little airflow, making them an energy efficient capture solution. However, they must be continually repositioned as the welder moves in order to maintain their capture efficiency. Fume arms work best for smaller parts that are very size-consistent and remain stationary on the bench, reducing the need for manual repositioning of the arm.

Backdraft/Sidedraft Intake Plenum

This system consists of inlet or grill connected to the main ductwork system and mounted behind or beside the welding zone. It is best suited for bench or fixture welding applications with larger parts of fairly consistent size and placement on the bench or fixture. Unlike fume arms, there is no need for the operator to adjust anything; the air intake is always in the correct position. The backdraft/sidedraft plenum must be sized for the largest possible part that will be welded in front of or beside it. It uses more airflow, and thus more energy, than a fume arm.

Downdraft Table

Downdraft tables are most often used for cutting and grinding applications. Unlike thermally generated weld fumes, which rise, dust created by cutting or grinding falls out of the air. A downdraft table assists gravity with a downward airflow that pulls particulates out of the air and into a collector.

AMBIENT AIR FILTRATION SYSTEMS

An ambient filtration system is an excellent option when you need to clean the air for the facility as a whole. Ambient systems may be stand alone, or they may be a secondary solution to remove dust and fumes that are not captured by the primary source capture system.

Ambient filtration systems come in three basic types:

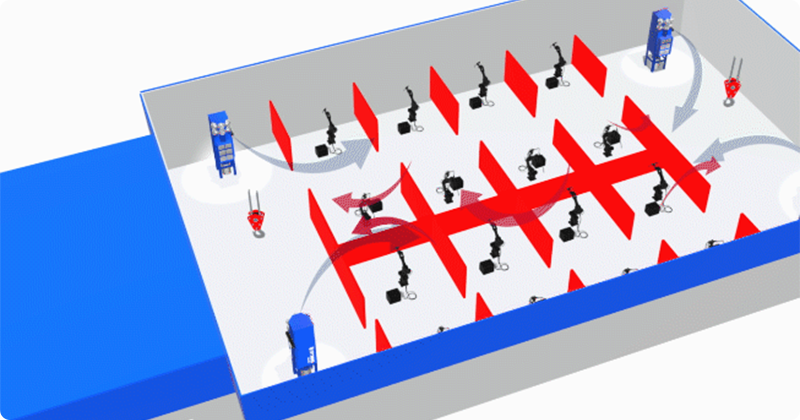

Ducted push-pull systems

The most traditional option, ducted push-pull systems keep the filtration equipment off of the floor and out of the way. These systems may be ideal for large facilities that desire constant ambient air turnover throughout the entire facility and/or do not change their floor plans or production line configurations frequently. These systems rely on a system of ducts up near the ceiling which carry fumes and particulates to a dust collector. Rising fumes and particulates are pulled into ductwork on one side and clean air is pushed out from ducts on the other side, creating air currents that continually pull contaminated air away from workers and into the system. Dust collectors can be placed overhead or outside of the building, saving considerable floor space.

Ductless floor systems

These systems consist of standalone dust collectors that sit on the factory floor. A ductless system, such as Senturion Vortex™, is easier to install and eliminates expensive ductwork. Dust collectors can be positioned where they are needed around the factory floor and can be easily moved whenever production lines are reconfigured. Each dust collector creates its own circular local airflow pattern, pulling dirty air in and pushing clean air out. These units tend to have higher airflow per unit, so you may need fewer dust collectors overall. If you need to add more capacity, you can simply place another unit on the floor. A ductless system may be ideal for facilities that reconfigure production lines often and where there is plenty of floor space.

HYBRID SOURCE CAPTURE/AMBIENT AIR FILTRATION SYSTEMS

Many facilities use a combination of source capture and ambient systems. Depending on the system selected and the application it is used for, a correctly used source capture system will collect between 70%-90% of fumes. This may have been enough in the past, but tightening air quality regulations and an increased awareness of health hazards are prompting many companies to add an ambient system to collect fumes and particulates that source capture may miss. A secondary ambient system can be especially helpful in the following situations:

- Welding large equipment that requires welders to move around the pieces they are welding.

- Relying on manually positioned fume arms while welding large parts.

- Utilizing open smoking bins where freshly welded parts are allowed to cool.

NEED HELP CHOOSING THE RIGHT INDUSTRIAL AIR FILTRATION SOLUTION?

Talk to one of our solution specialists.