The Risks of Cadmium Exposure

Reducing Occupational Exposure to Cadmium

Reducing Occupational Exposure to Cadmium

Cadmium is among the most toxic metals that workers can be exposed to in industrial environments. Are your employees at risk? Here’s what companies need to know about cadmium exposure, including health effects, OSHA regulations and mitigation strategies.

What is Cadmium?

Cadmium is a naturally occurring element commonly found alongside zinc ores. Most cadmium used in industrial processes is a byproduct of zinc production. At room temperature, cadmium is a bluish-grey, soft metal. Its low melting point, natural corrosion resistance and conductivity have made cadmium highly useful for a number of industrial applications.

Some of the most common applications include:

- Coatings, especially anti-corrosive coatings

- Electroplating of steel components to reduce corrosion

- Pigments for paints, coatings and glass (cadmium salts produce brilliant and durable reds, yellows and oranges)

- Batteries, especially rechargeable nickel-cadmium batteries

- Stabilization of plastics

- Control rods for nuclear reactors

- Solar panels

Over the last decade, concerns about cadmium toxicity and changing regulations have prompted many industries to reduce their reliance on cadmium and look for less-toxic alternatives. Its use in battery production and coatings has declined significantly in recent years. However, there are still many workers exposed to the toxic effects of cadmium in the industries where it remains in use.

Health Risks of Cadmium Exposure

Cadmium is considered both highly toxic and carcinogenic (cancer causing). Exposure can result in both acute and chronic health impacts. Because it is not easily metabolized and eliminated by the body, it tends to accumulate in body tissues over time, especially in the liver, kidneys, muscle and bone. For this reason, cadmium is considered to be a cumulative toxin.

The body systems most impacted by cadmium exposure, both acute and chronic, are:

- Lungs

- Kidneys

- Bones

Acute effects of inhaled cadmium exposure include lung irritation and breathing difficulty along with flu-like symptoms that resemble the more common “metal fume fever” associated with weld fume exposure. However, with cadmium exposure, the illness can progress to pulmonary edema and chemical pneumonitis, severely restricting lung capacity. In severe cases, this can be fatal. When cadmium is ingested, it can cause nausea, vomiting, abdominal pain and diarrhea.

Chronic effects result from exposure to cadmium over time. Because of the way cadmium builds up on the body, even low levels of chronic cadmium exposure can lead to damage to body systems over time. These effects can include:

- Chronic lung disease such as emphysema or Chronic Pulmonary Obstructive Disease (COPD)

- Lung cancer

- Kidney disease and chronic renal failure

- Bone lesions or reduced bone mass

There is also some evidence that cadmium exposure may cause developmental problems in fetuses or result in higher incidence of preterm delivery when the mother is exposed during pregnancy, though more research is needed.

Because tobacco is also a significant route of cadmium exposure, the effects of occupational exposure to cadmium may be amplified in smokers.

Who is at Risk?

By far, the most common route of occupational exposure is inhalation. While some workers may be exposed to cadmium through the skin, especially when working with paints and coatings, it is believed that only a very small amount of cadmium is absorbed this way. Oral ingestion is a concern in some parts of the world where crops absorb cadmium from the soil, but is not considered a significant route of industrial exposure.

Workers most at risk for cadmium exposure are those involved in processes that heat, cut or grind cadmium-containing materials. In general, fumes created by thermal processes such as welding or electroplating are more dangerous than dust created by cutting and grinding. This is because smaller particulates produced by thermal processes are inhaled deeply into the lungs where they are more likely to be retained, cross into the blood stream and be carried to other body systems.

Processes that put workers at high risk for cadmium exposure include:

- Electroplating of steel components

- Welding materials that have anti-corrosive or pigmented coatings containing cadmium or cadmium oxides

- Machining of materials with cadmium-containing coatings

- Plastic processing where cadmium is used as a stabilizer

- Production of paints, coatings or ceramics where cadmium is used in the pigments

Understanding Regulations for Cadmium Exposure

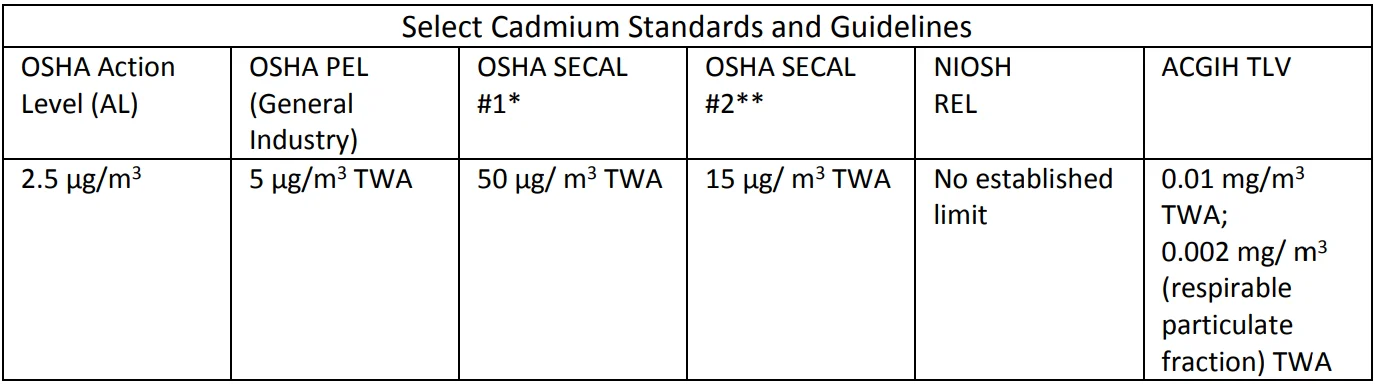

The Occupational Health and Safety Administration (OSHA) has implemented standards to protect industrial workers from cadmium exposure. There are three OSHA exposure limits that employers must observe:

- Action Level (AL): The airborne level of cadmium that creates a hazard to workers. If the AL is exceeded, employers must conduct exposure monitoring, initiate a medical surveillance program for employees who are at or above the AL on 30 or more days per year, and provide a respirator to any employee that requests one. The action level for workplace exposure to cadmium is 2.5 micrograms per cubic meter of air (2.5 µg/m3) calculated as an 8-hour time-weighted average (TWA)

- Permissible Exposure Limit (PEL): A time-weighted average concentration that must not be exceeded during any 8-hour work shift of a 40-hour workweek. OSHA has set a

PEL of 5 micrograms of cadmium per cubic meter of air (5 µg/m3) for all cadmium compounds, dust, and fumes.

- Separate Engineering Control Air Limit (SECAL): Specific exposure limits that apply to select and defined industries and processes. OSHA has set SECALs for cadmium exposure for industries where meeting the PEL is not considered technically

For industries not subject to a SECAL, the PEL is the standard that companies are expected to adhere to. Failure to keep cadmium exposure within the PEL will result in penalties and fines. Companies should check the OSHA standards for their industry to verify the PEL or SECAL that applies to them.

The American Conference of Government and Industrial Hygienists (ACGIH) has set their own Threshold Limit Values (TLVs®) for cadmium exposure based on available scientific literature documenting the health effects. While PELs and SECALs are set by OSHA with some consideration to the technical feasibility of the limit, TLVs are set purely based on human health impact. ACGIH guidelines do not have the force of law, but if they are lower than OSHA standards, many companies prefer to aim for the lower guideline in order to provide maximum protection for their workers.

- Nickel/cadmium battery industry (plate making & preparation), zinc/cadmium refining, pigment processing (calcine, crushing, milling and blending), plastic stabilizer production, lead smelting

** Nickel/cadmium battery industry (all other), pigment manufacturing (all other), mechanical plating

Process and Engineering Controls for Reducing Cadmium Exposure

OSHA mandates that changes to work processes and engineering controls be used as the first lines of defense against cadmium exposure in the workplace. Personal protective equipment (PPE) should only be used as a backup in cases where the PEL cannot be met using engineering controls.

Since inhalation is the most significant exposure pathway for cadmium, controlling air quality is the most important step companies can take to reduce exposure levels. Ventilation or air filtration systems should be used to remove fumes and particulates from the air.

- Ventilation systems simply exhaust contaminated air to the outside and pull fresh air in. These are simple to install and operate, but can result in significant energy losses when heated or cooled indoor air is exhausted and outdoor-temperature air is brought in. In addition, exhausting contaminated air to the outside may put companies out of environmental compliance. Cadmium has known environmental impacts and is on the Environmental Protection Agency (EPA)’s National Emission Standards for Hazardous Air Pollutants (NESHAP) list, so exhausting unfiltered air containing cadmium to the outside is not

- Air filtration systems use dust collectors to pull contaminated air through filters and return clean air back to the facility. While they are more expensive to install and

operate than ventilation systems, they will return significant energy savings for the facility as indoor temperature air is kept inside. They also keep cadmium and other dangerous emissions out of the environment. Filtration systems are a better choice for most companies engaged in processes that produce cadmium emissions.

Air filtration systems can be further classified as source capture or ambient.

- Source capture systems collect contaminated air close to the emission source. Source capture should be used wherever possible to keep emissions out of the breathing zone and prevent contamination of the ambient facility air. Source capture also uses less energy; the closer to the source particulates can be captured, the less air the dust collector will need to move. Source capture systems include hoods, backdraft and sidedraft tables, downdraft tables and portable fume collection

- Ambient systems turn over air for the entire facility. They may be used alone when source capture is not technically feasible or as a backup system to clear fumes that escape source

Engineering controls, including air filtration equipment, should be used to reduce the levels of cadmium-containing dusts in the air to as low a level as is technically feasible. When PELs cannot be met any other way, PPE such as Powered Air Purifying Respirator (PAPR) systems may be used to protect workers exposed to cadmium-containing fumes and dusts. Companies in industries with higher SECAL standards due to the technical difficulty of controlling cadmium dust should consider providing PPE to workers whose exposure levels are above the ACGIH TLV.

In addition to installing appropriate air quality equipment, companies should consider other steps to reduce the levels of cadmium produced by processes and encountered by workers. For example:

- Consider replacing cadmium-containing coatings and materials with less toxic alternatives.

- Implement housekeeping procedures that reduce the spread of cadmium-containing dusts through the

- Ensure that workers do not eat or drink in areas where they may be exposed to cadmium dusts, as this will put them at risk of accidental

- Install curtains or walls to partition off cadmium-producing processes and make cadmium-containing dust easier to contain and

The Bottom Line on Cadmium Dust Control

Good engineering controls and industrial hygiene protocols will protect workers from the dangerous effects of cadmium exposure. They will also reduce exposure to other dangerous elements and compounds that are often concurrent with cadmium, including nickel, zinc, magnesium, manganese, hexavalent chromium and lead.

Designing an effective air quality system to control cadmium exposure takes experience and skill. RoboVent air quality system designers use scientific principles to evaluate dust- and fume-producing processes, analyze current exposure levels, and optimize systems for capture efficiency and energy savings. If you’re concerned about cadmium exposure in your facility, contact us to get started.

Resources

- Centers for Disease Control and Prevention (ND) Cadmium

https://www.cdc.gov/biomonitoring/Cadmium_FactSheet.html

- Occupational Health and Safety Administration (ND) U.S. Department of Labor. https://www.osha.gov/Publications/3136-08R-2003-English.html

- Occupational Health and Safety Administration (1992) Occupational Health and Safety Standards: Cadmium. Standard 1910.1027. U.S. Department of Labor. https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=standards&p_id=10035

- RoboVent (2017) Indoor Air Quality 101. https://www.robovent.com/indoor-air- quality-101/

- Tucker, P. (2008) Cadmium Toxicity. Agency for Toxic Substances & Disease Registry (ATSDR) https://www.atsdr.cdc.gov/csem/csem.asp?csem=6&po=0

REQUEST MORE INFORMATION