How Smart Control Systems Cut Energy Costs for Dust Collection

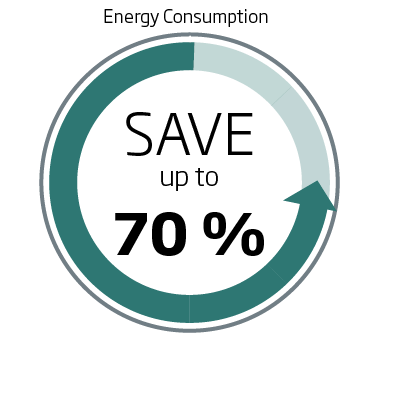

Dust collection is a critical component of industrial air quality management, but many traditional dust collection systems operate inefficiently, consuming more energy than necessary. Intelligent control systems like the Nederman SAVE system offer a smarter, more efficient way to manage airflow—reducing energy costs by up to 70% while maintaining optimal dust collection performance.

Contact us to learn whether the SAVE system is right for you and find out how you could qualify for energy incentives to cover the cost.

How Intelligent Control Systems Save Energy

Intelligent control systems are advancing dust collection by automating and optimizing airflow management. These systems continuously monitor conditions such as airflow demand, filter loading and fan performance, adjusting in real-time to ensure efficient operation without unnecessary energy consumption. By dynamically controlling how much air is moved and when, intelligent dust collection solutions reduce costs, extend equipment life and improve overall system performance.

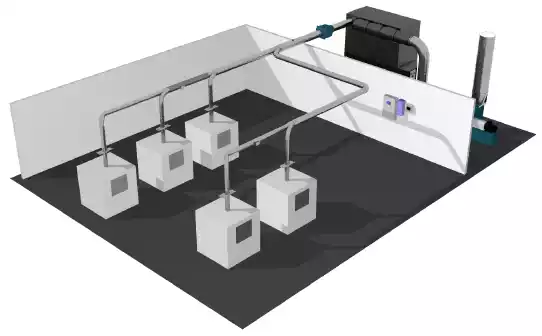

In a typical manufacturing environment, there are multiple production lines or machines that create process dust. In a centralized dust collection system, each of these machines or processes is connected to a large central dust collector via a system of ductwork. While some production processes run 24/7, most do not. In fact, most machines cycle on and off many times over a shift and may only be utilized 40-60% of the time.

Traditional dust collection systems operate at a fixed speed, meaning fans and blowers run at full capacity even when only partial airflow is required. The system is sized on the assumption that all drop points or machines require maximum airflow 100% of the time—even though this is rarely true in practice. This results in excessive energy consumption and increased maintenance needs due to unnecessary system strain.

In contrast, intelligent control systems adjust system performance based on real-time operating conditions. Instead of running at a constant speed, they regulate fan output, motor speed and damper positions to precisely match airflow requirements at any given moment. When machines are not in use, a damper system shuts off airflow, and fan speed for the dust collector is reduced to compensate for the reduced airflow (CFM) requirements. This approach significantly improves energy efficiency, equipment longevity and overall dust collection effectiveness.

An advanced control system like the Nederman SAVE system optimizes airflow and reduces waste by:

- Adjusting dampers dynamically to control airflow for different work areas or machines.

- Modulating dust collector fan speeds to match real-time dust collection needs, based on which machines are operating at any given time.

- Monitoring filter loading to regulate airflow and prevent unnecessary power usage.

By automatically scaling system operation to actual facility demands, intelligent control systems can cut energy consumption by up to 70% compared to traditional dust collection setups.

The Nederman SAVE System: Advanced Airflow Control

The Nederman SAVE system is an advanced demand-based control solution that continuously adjusts airflow and power usage based on real-time operating conditions and demand. Instead of running dust collection fans at a fixed speed, SAVE dynamically optimizes performance, ensuring efficient dust collection only where and when it’s needed.

How the SAVE System Works

The Nederman SAVE system is designed for centralized dust collection systems that service multiple machines or workstations. Instead of running at full capacity all the time, SAVE continuously adjusts airflow based on real-time demand. Sensors detect when individual machines are on or off, and the system automatically modulates airflow and fan speed to ensure efficient dust extraction only where it’s needed.

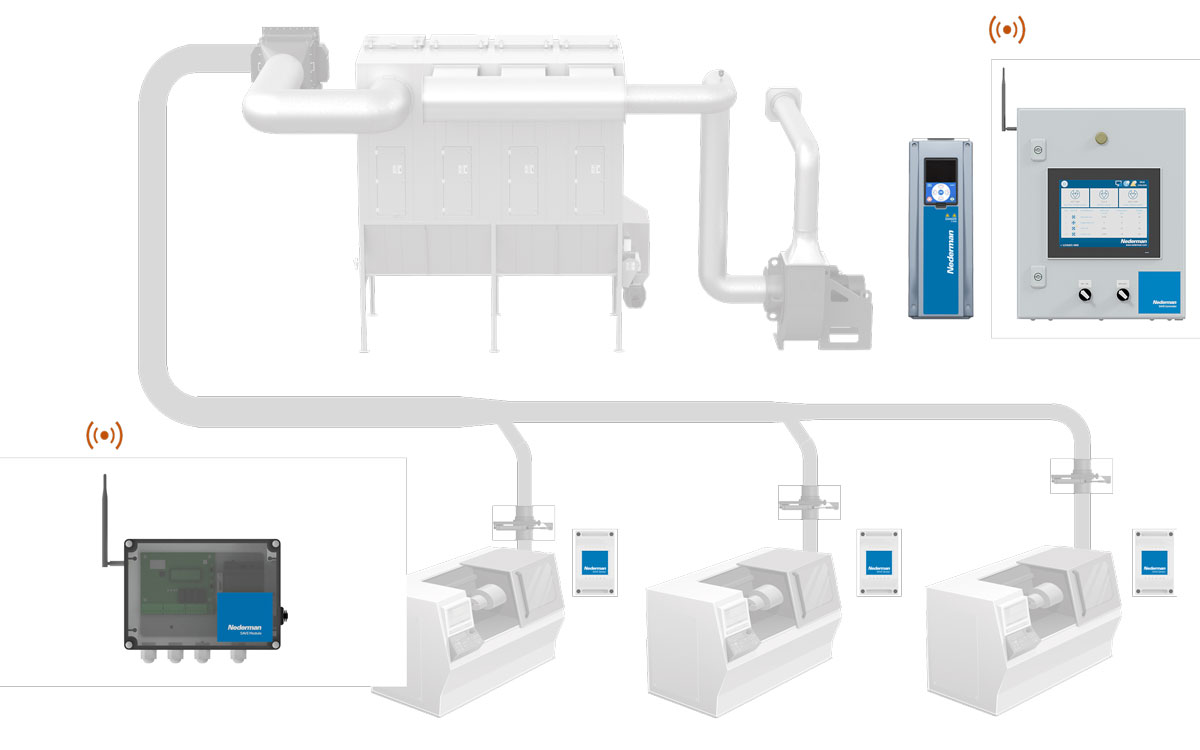

The SAVE system consists of several key components that work together to optimize energy use and system performance.

- SAVE Sensors: Installed at each machine to track real-time operation and detect when a machine is actively generating dust.

- SAVE Modules: Wireless communication modules that send sensor data to the main controller, allowing it to monitor system-wide activity.

- Autogate Dampers: Installed at each extraction point, these dampers open or close automatically based on machine status, directing airflow only to active workstations.

- VFD Motor: A variable frequency drive (VFD) motor on the dust collector adjusts fan speed dynamically, ramping up or down based on real-time airflow requirements to reduce energy waste.

- Airflow Monitor: Continuously measures airflow and system pressure, ensuring proper dust extraction and maintaining the correct transport velocity for captured particles.

- SAVE Controller: The system’s intelligent control hub, which collects data from the SAVE modules and automatically adjusts dampers and fan speed for optimized performance and energy efficiency.

By automating airflow adjustments, the SAVE system ensures that only the necessary amount of air is moved at any given time. This optimizes airflow based on operating requirements, reduces strain on system components, and significantly lowers energy consumption—without compromising dust collection performance.

Unlocking Productivity Insights

Beyond energy savings, the Nederman SAVE system provides valuable productivity data that helps businesses optimize operations. By continuously monitoring machine utilization, airflow demand, and system performance, SAVE collects real-time data that can be used to identify inefficiencies, track equipment usage patterns, and improve overall facility management.

When integrated with Nederman Insight, a cloud-based IIoT platform, SAVE enables remote monitoring, data visualization and performance reporting. This allows facility managers to see exactly when and where extraction is needed, optimize production workflows and make informed decisions about system maintenance and upgrades. The ability to analyze historical data also helps in predictive maintenance planning, reducing unexpected downtime and improving overall operational efficiency.

With this level of data-driven control, businesses can not only reduce energy waste but also enhance productivity, extend equipment life and ensure their dust collection system is always operating at peak performance.

The Benefits of the Nederman SAVE System

Implementing the Nederman SAVE system not only optimizes energy efficiency but also contributes to a safer, more productive and more cost-effective industrial environment. The system delivers significant benefits for industrial dust collection systems.

- Significant Energy Reduction: By synchronizing fan performance with real-time extraction needs, the SAVE system can reduce energy consumption by up to 70% compared to traditional dust collection systems.

- Enhanced Safety and Compliance: SAVE improves employee safety and ensures compliance with OSHA and NFPA standards by monitoring airflow and maintaining appropriate transport velocities, thereby reducing risks associated with combustible dust.

- Increased System Capacity: By adjusting fan operation based on actual airflow requirements rather than the theoretical maximum, SAVE enables many manufacturers to reduce the size of their dust collectors. SAVE can free up capacity within existing systems and potentially reduce the size, footprint and installation costs of new dust collection systems.

- Reduced Maintenance Needs: Optimized airflow management leads to consistent extraction and reduced wear and tear on the dust collection system, which increases equipment life, extends maintenance intervals and reduces downtime.

Is the SAVE System Right for Your Facility?

If you’re looking to reduce energy costs, improve dust collection efficiency and extend equipment life, the Nederman SAVE system is a powerful solution. Whether you operate a welding shop, metal fabrication facility, woodworking plant or any other industrial workspace, SAVE can help you optimize airflow, cut waste and enhance productivity.

At RoboVent, we specialize in energy-efficient dust collection solutions that maximize performance while minimizing costs. We can help you determine if the Nederman SAVE system is the right fit for your facility and guide you through available energy incentive programs to offset upgrade costs.

Contact us today to learn how intelligent control systems like SAVE can help you save money and improve workplace air quality.

Contact Us With Your Questions!

SUBSCRIBE TO

BLOG UPDATES