Dust-Creating Processes in Electrode Manufacturing

Electrode production is one of the dustiest parts of the battery manufacturing process. Electrode manufacturing varies widely among battery types; this article mainly focused on electrodes for Lithium-ion (Li-ion) batteries such as those used for electric vehicles (EVs) and consumer electronics. Dust is created during several processes for both cathode and anode preparation, including material preparation and mixing, slurry preparation, calendering, and slitting. Other processes, such as coating and drying, do not generate much dust themselves; however, it is important to have dust control systems in place to prevent dust from other processes from contaminating coating and drying lines.

Health and Safety Risks for Electrode Dust

Regulations for the Battery Industry

Battery manufacturers involved with electrode production must comply with all environmental, worker health and safety regulations set by national, state and local regulatory agencies. Proper dust control and containment are necessary to meet regulatory standards related to worker exposure, combustible dust safety, and environmental protection. These regulations include:

Dust Control Challenges for Electrode Production

Dust collection during electrode production in battery manufacturing presents several challenges due to the nature of the materials involved, the requirements for maintaining a clean environment, and the need to ensure worker safety. Some of the primary challenges include:

RECOMMENDED SOLUTIONS

OTHER SOLUTIONS

TOTAL FILTRATION PARTNER

RoboVent is your full turnkey resource for clean air in industrial environments. From facility testing and engineering, to installing equipment, providing replacement filters and preventive maintenance, RoboVent is ready to manage the whole process.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.

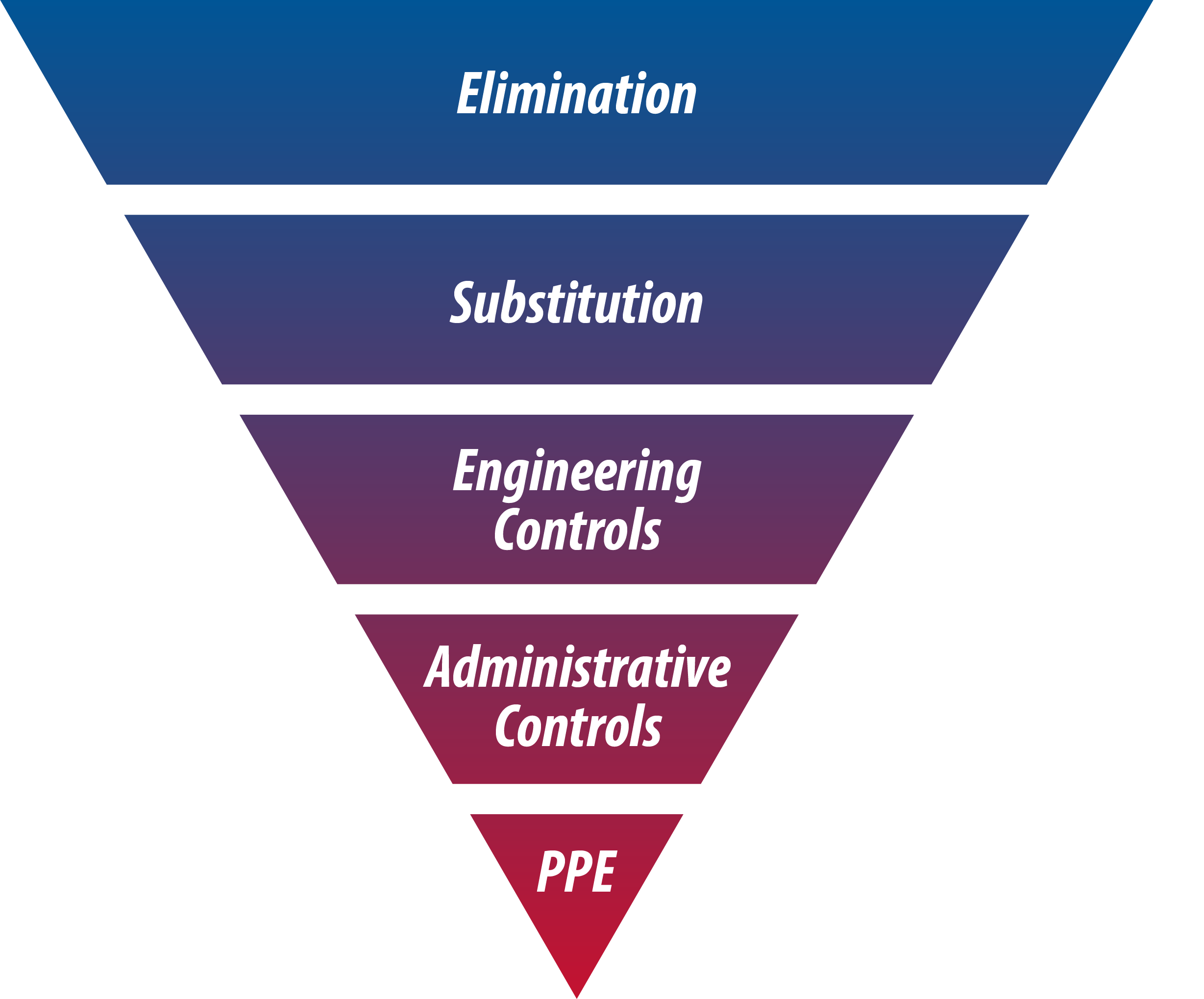

Worker health and safety:

Worker health and safety:  Combustibility and explosiveness:

Combustibility and explosiveness: