A Hot Tip on Robotic Tip Extraction

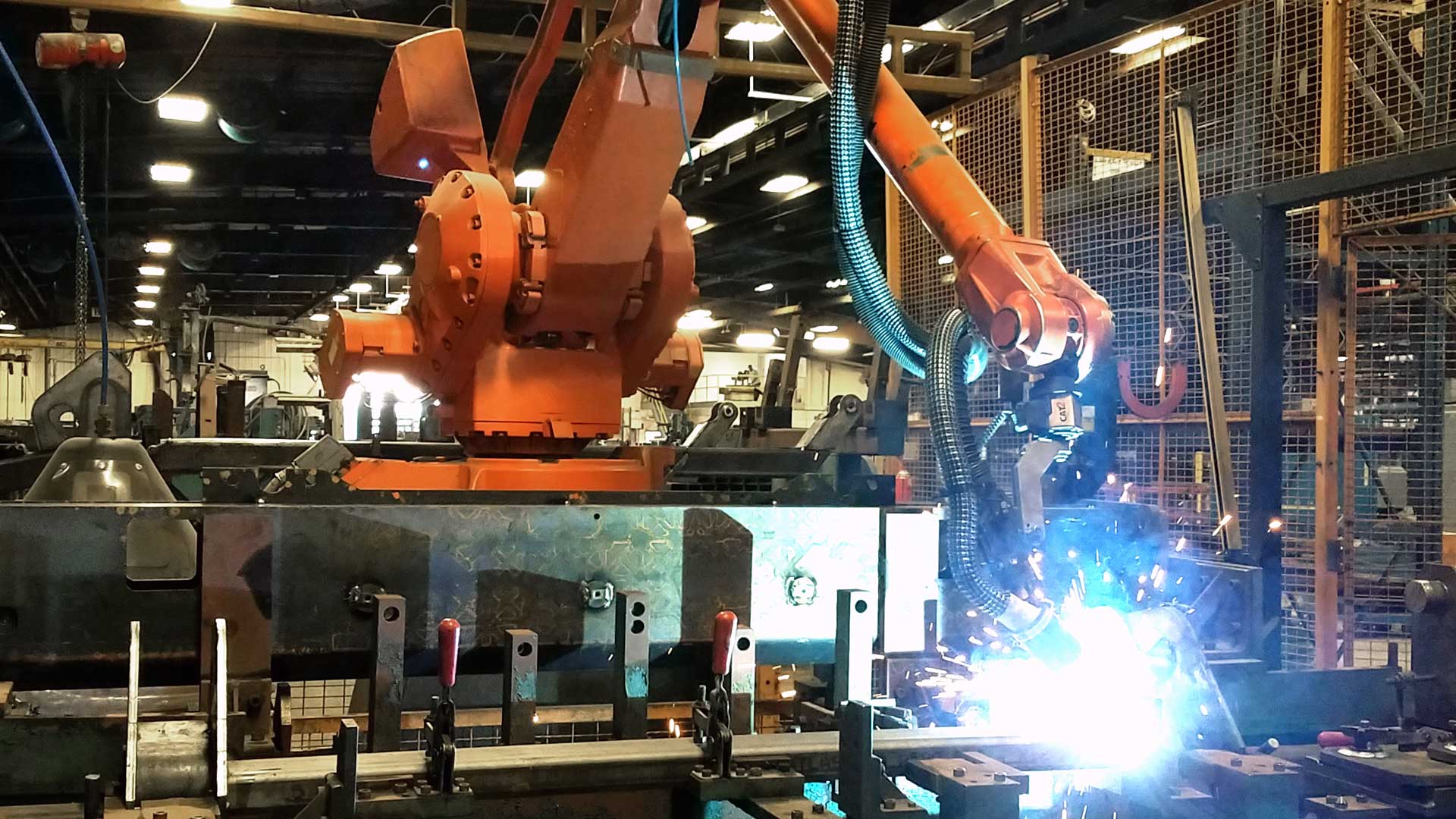

Robotic welding operations that are too large to fit under a fume extraction hood—like welding on a trailer or piece of heavy machinery—need an alternate method of fume capture. Fortunately, innovations in the area of tip extraction have advanced the technology considerably in recent years.

Previous tip extraction technology — most often found in fume guns — had many flaws. Most significantly, the nozzle design and extraction pressure caused turbulence that interfered with welding gases. Poor welds were a common phenomenon. Also, the units were heavy and cumbersome. However, these issues are no longer a problem. Nozzle design has been improved, new lightweight materials have been used and today’s extraction systems can control air flow at precise rates.

Today’s tip extraction is so advanced it can be applied to robotic welding. The combination of these two technologies offers the following benefits:

- Nearly nonstop welding on pieces of any size with constant fume capture

- Fume capture rates of up to 95%

- Perfect welds

- Protection of workers’ health throughout the entire facility

- Space-saving in your facility

- No interference with overhead cranes or equipment

- Reduced need for ambient air filtration equipment

How to Implement Robotic Tip Extraction

Applying tip extraction to a robotic welding unit is usually a custom job. It’s important that the extraction hose doesn’t interfere with the welding arm and that the tip is perfectly placed. At RoboVent, engineers create a 3D model of each welding torch in order to manufacture a tip extractor that fits it exactly.

Robotic tip extraction delivers energy savings, as well. The smart system runs when the welding arc is on and turns off when the arc is off, ensuring that the system only runs when needed. Also, tip extraction requires much less air flow than larger systems—a 3-4 HP motor is enough to run a hi-vac collector, versus the usual 10-15 HP needed for a typical dust collector. This results in serious energy savings over time.

Robotic welding once looked like science fiction but has become commonplace. Robotic tip extraction seems poised to do the same. To learn more about this air quality solution, see here.

Contact Us With Your Questions!

SUBSCRIBE TO

BLOG UPDATES