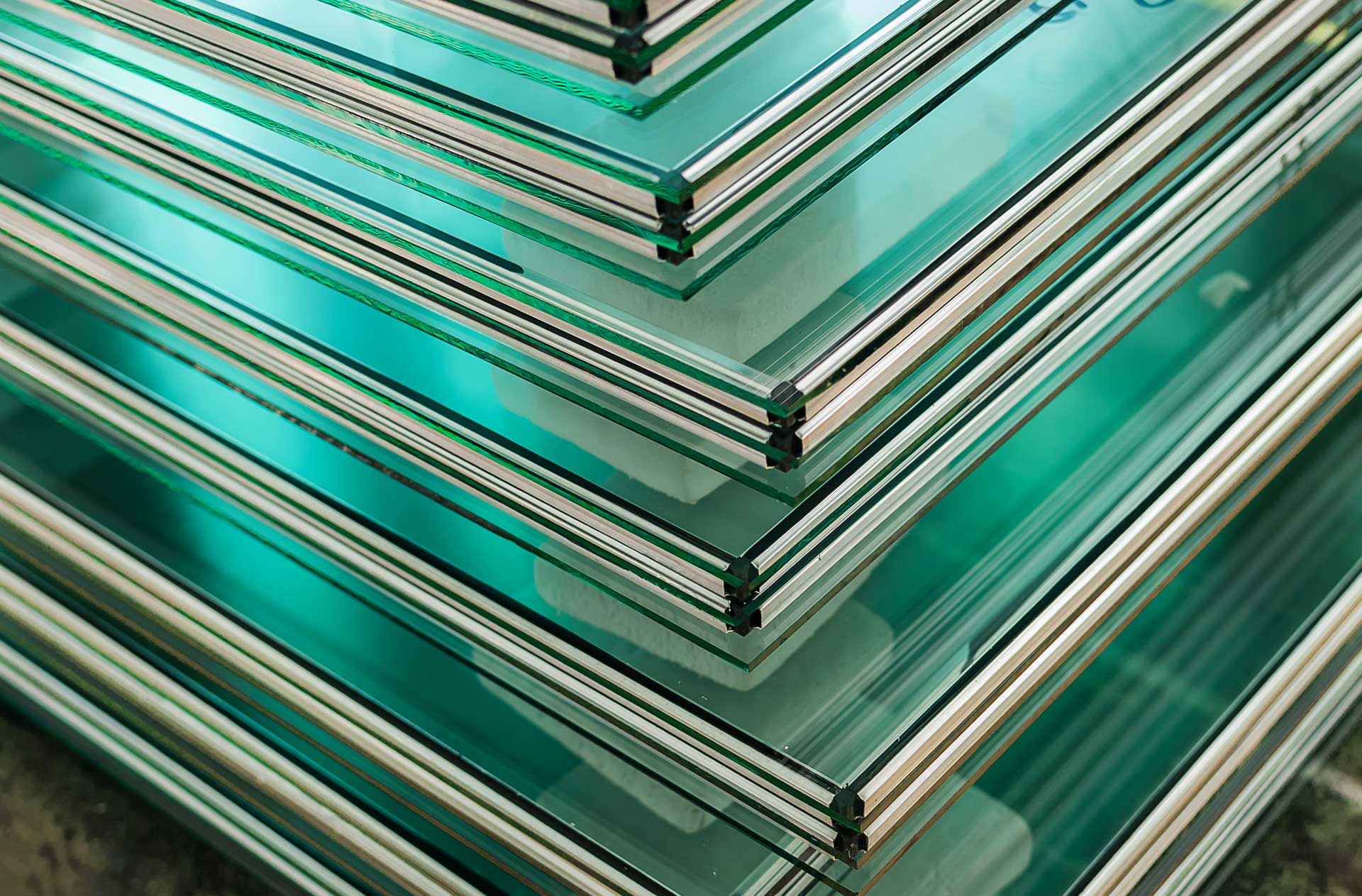

DUST AND FUME COLLECTION CHALLENGES IN THE GLASS INDUSTRY

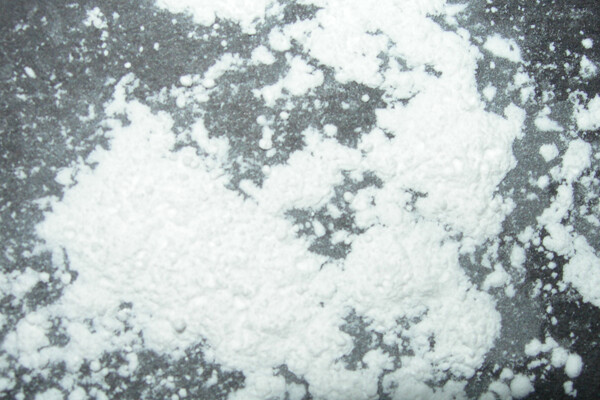

The biggest change in regulations applying to glass manufacturing has been the 2016 change to silica dust standards. The Occupational Safety and Health Administration (OSHA) issued these rules to tighten the regulation of this dust in the workplace. The rules are significantly more stringent than previous regulations. While some manufacturers will already be in compliance, many will have to take serious measures to address the change.

For years the evidence had been growing that the previous limits on silica dust were not keeping workers safe. When inhaled, silica dust can travel deeply into the lungs and cause a number of health problems. The dust is implicated in lung cancer as well as chronic bronchitis and other respiratory diseases. Over time, it can damage other bodily systems, most notably the kidneys. Prolonged exposure can lead to silicosis, a serious disease caused by damage to the lining of the lungs. Chronic silicosis develops with even low-level exposure over time, reducing lung capacity until sufferers need oxygen to survive.

OSHA’s new limit on silica dust cuts the permissible exposure limit (PEL) by half. The new limit is 50 micrograms per cubic meter of air. As with most PEL’s, this limit is measured as an 8-hour time-weighted average. Due to the dangers of silica dust, manufacturers can’t settle for filtering out 80% of so of the dust, as they might with other dusts. With silica, a manufacturer needs to aim for capturing and controlling at least 99.9% of the dust.

The first step in addressing this, or any, air quality issue is to obtain a baseline measurement of the current state of your air quality. This should be done at both the source of the dust and in the ambient air. Professional, certified, third-party services exist to measure and report on air quality.

In order to clean your air to the necessary standard, you will need a highly efficient dust control system that filters the air and, most likely, is able to return that clean air to your facility. Such a system will probably require a source capture device, such as a well-designed capture hood that pulls in contaminated air as it is produced.

While these efforts are significant, the costs of non-compliance are likely to be greater. OSHA is expected to step up the enforcement of silica dust standards. Meanwhile, the need to protect workers’ health is pressing and is always the best reason for maintaining clean air.

Related Resources

SOLUTIONS FOR THE DUST AND FUMES IN THE GLASS INDUSTRY

Using standard ventilation systems to blow contaminated air out of the working environment will most likely not be sufficient to meet OSHA regulations. RoboVent has decades of experience producing air filtration equipment well suited to glass manufacturing. Our dust collectors are efficient and powerful systems that can clean and return the air to your facility.

From small, portable solutions to large grid configurations, RoboVent offers a solution for every application. Our source capture solutions will allow you to collect dust at the source. Our cutting-edge filters take the harmful dusts out of the air and leave the air clean enough to return to the facility. Keeping a closed system helps save energy, since you avoid exhausting your heating and air conditioning to the outside.

RoboVent is pushing technology forward, as well. For example, RoboVent’s VentMapping software creates a computer model that simulates the airflow within your facility. This allows our engineers to analyze the variables of your dust production, facility layout and air currents in order to design the best filtration system.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.