BLOG: FEATURED ARTICLE

Cartridge Dust Collector Troubleshooting Guide: 10 Common Problems

Dust collector not working? Before you call for service, check out our troubleshooting guide for cartridge dust collectors. Whether your

Cartridge Dust Collector Troubleshooting Guide: 10 Common Problems

Dust collector not working? Before you call for service, check out our troubleshooting guide for cartridge dust collectors. Whether your dust collector is not

How Smart Control Systems Cut Energy Costs for Dust Collection

Dust collection is a critical component of industrial air quality management, but many traditional dust collection systems operate inefficiently, consuming more energy than necessary.

Energy Incentives for Dust Collection: Unlocking Savings While Improving Efficiency

Upgrading your dust collection system can lead to big energy savings. But did you know your power company may help cover the bill? Many

Cutting Energy Costs: 10 Strategies for Smarter, More Efficient Dust Collection

Industrial dust collection and air filtration systems are essential for maintaining air quality, protecting worker health and ensuring compliance with environmental regulations. However, they

Built to Last, Engineered for Safety: Air Quality Solutions for Heavy Equipment Manufacturing

From bulldozer booms to crane chassis, the machines that shape our world are built through hard, hot, gritty processes: welding, cutting, grinding and machining

Hand Plasma Cutting Dust and Fume Control

Supporting Clean Air Compliance in Heavy Equipment Manufacturing and Fabrication Shops Hand plasma cutting is a powerful and versatile method, but it produces

The Heavy Equipment Market Is Heating Up. We’re Ready.

Heavy equipment manufacturing presents some of the toughest air quality challenges in the industrial world. To stay competitive and compliant, manufacturers must tackle these

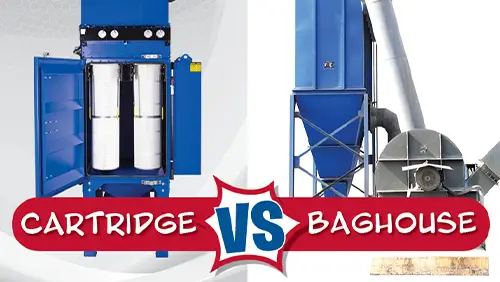

Baghouse vs. Cartridge Dust Collectors: What’s the Difference?

When it comes to industrial dust collection, choosing the right system is critical for efficiency, performance, and compliance. Two of the most common options

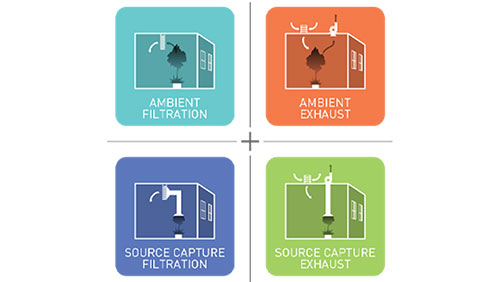

Process Dust vs. Nuisance Dust: What’s the Difference?

Industrial processes can create large volumes of toxic or hazardous process dust, which must be controlled to protect worker health and safety.

Extending the Life of Your Dust Collector

A well-designed and properly maintained dust collection system—like this dual Senturion setup—can deliver reliable performance and a longer service life. A properly

Repair or Replace the Dust Collector? How to Make the Decision

An industrial dust collector is a critical investment in facility safety and compliance. With proper care and maintenance, a properly designed dust collection system

NFPA 660 Compliance: Understanding Combustible Dust Standards

The National Fire Prevention Association (NFPA) has updated and consolidated its combustible dust standards into a new overarching standard: NFPA 660. The new standard