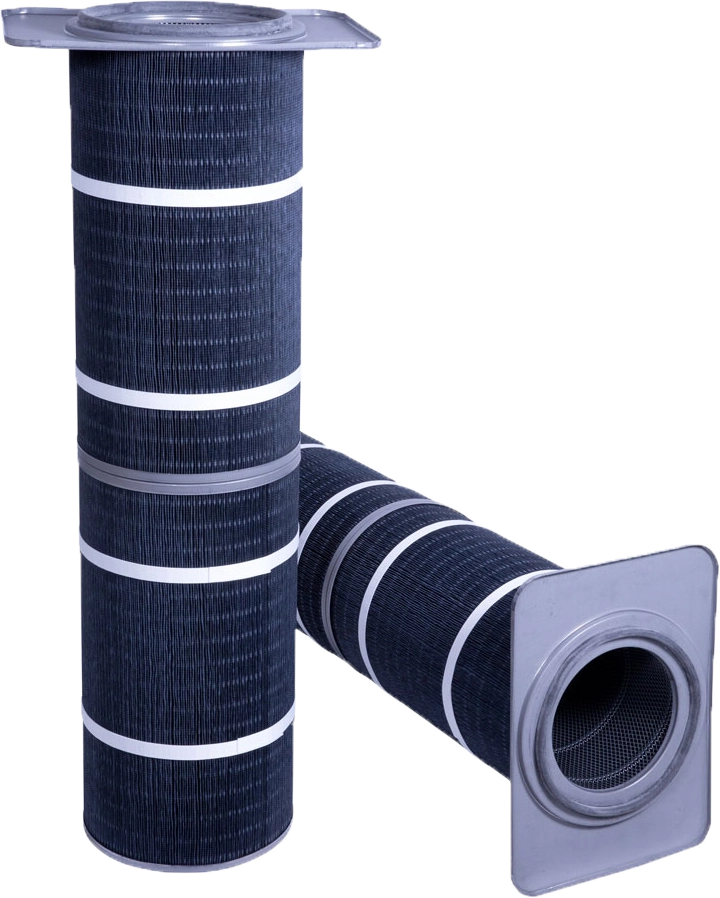

PLEATLOCK DUST COLLECTOR CARTRIDGE FILTERS

Why PleatLock?

35% more media extends filter life and saves money

- More on-time with fewer filter changeouts

- Maximizes pleats per inch in cellulose polyester blended media.

- MERV 11 and MERV 15 available

- Excellent efficiency on sub-micron particles

35% more media captures more particulate and extends filter life.

PleatLock filters are now standard in all RoboVent dust and fume collectors. The reason is simple – they offer more media and better performance for less money. With more pleats per inch of filter than minipleat technology, PleatLock filters provide 35% more media to capture weld fume and metal cutting particulate, effectively extending filter life. This filter technology provides longer intervals between filter changes, less downtime for maintenance and greater savings on the cost of replacement filters.

Available in A15, A16, M11 & Oleophobic.

MiniPleats vs. PleatLock

| RMO | PleatLock |

|---|---|

|

|

PLEATLOCK FILTERS ONLINE CATALOG

Find what you need in our online filter catalog. Browse, filter and sort from hundreds of available filters, parts and equipment. Our catalog lets you select from different sizes and quality to find the correct filter for your application. Once you've found your filter, use the inquiry cart to notify our sales team and place an order or get more information on those products.

The Power in the Pleats

RoboVent’s PleatLock design embosses “locks” or “dimples” on both the inside and outside of the filter to maintain consistent pleat spacing. The embossed dimples prevent the pleats from pinching or collapsing and help keep channels clean as air enters and exits the filter. As a result, the entire filter surface is available to capture particulate. PleatLock technology the ideal choice for both cellulose polyester blended medias and can be coated with nanofiber.

Manufactured by RoboVent in Detroit, Michigan

PleatLock filters are made at our facility in Sterling Heights, Michigan, the same place that we manufacture dust and fume collectors. Rigorous quality control standards ensure that we produce, inspect, test and install high-quality filters in every piece of RoboVent equipment.

A16 PleatLock Premium Filter

A16 PleatLock premium filter media is a proprietary cellulose polyester blend with a fire retardant additive and an initial Minimum Efficiency Reporting Value of 16 (MERV16). The base media is enhanced with a direct-spray nanofiber to promote surface loading during operation and dust release during pulse-cleaning.

PleatLock Carbon Filters

- Cellulose/carbon blend media

- Direct-spray nanofiber layer for enhanced dust release

- Electronically conductive and fire-retardant finish

- Initial MERV15 filtration efficiency rating

35% more media extends filter life and saves money

35% more media extends filter life and saves money