Battery Recycling

Battery recycling is the last stage of the battery life cycle. Most types of batteries can be recycled, including nickel-cadmium, lead-acid, alkaline, and lithium-ion batteries. Of these, lead-acid car batteries and lithium-ion (or Li-ion) batteries used in EVs and consumer electronics make up the bulk of the battery recycling industry. In fact, lead-acid car batteries are a recycling success story, with a recycling rate of over 99%. With the growing market for EVs, the need for Li-ion battery recycling is expected to grow rapidly and could soon overtake the lead-acid recycling market.

Health and Safety Risks in Battery Recycling

Regulations for the Battery Recycling Industry

The battery recycling industry is heavily regulated to protect workers, communities and the environment. Regulations for battery recycling include environmental regulations set by the Environmental Protection Agency (EPA), worker health and safety regulations set by the Occupational Health and Safety Administration (OSHA), and fire and explosion safety standards set by the National Fire Protection Association (NFPA). These regulations and standards include:

Dust Control Challenges for Battery Material Handling and Processing

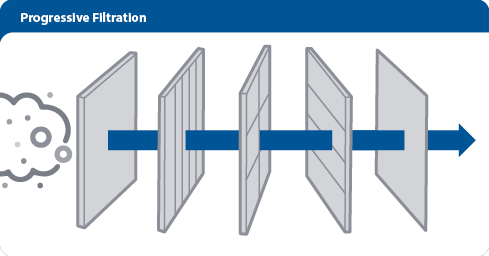

Dust collection for battery recycling can be challenging due to the volume, variety and types of dust and fumes created during the recycling process. Engineering controls such as dust collection and air filtration must be used as the primary means of worker protection before relying on personal protective equipment (PPE). Some of the primary challenges in dust collection for battery recycling include:

RECOMMENDED SOLUTIONS

OTHER SOLUTIONS

TOTAL FILTRATION PARTNER

RoboVent is your full turnkey resource for clean air in industrial environments. From facility testing and engineering, to installing equipment, providing replacement filters and preventive maintenance, RoboVent is ready to manage the whole process.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.

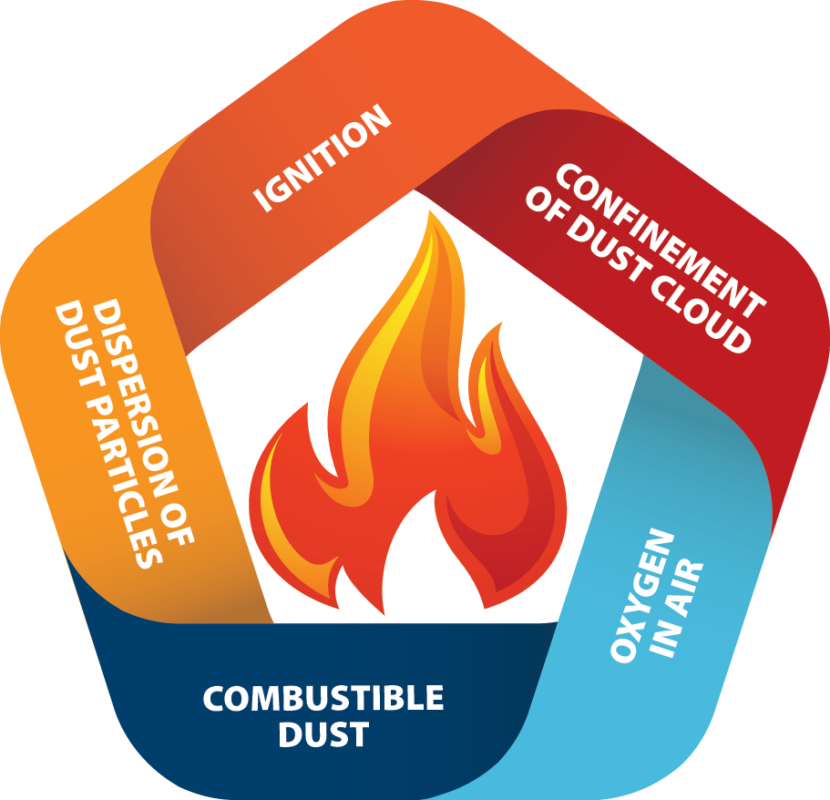

Fire and explosion risks: Dust produced during battery recycling may be combustible. Carbon black, graphite, lithium salts and silicon powder, among other battery materials, are highly combustible under the right circumstances. Plastic dust created when crushing battery casings for Li-ion batteries can also be explosive. If clouds of dust are allowed to form within an enclosure (including the dust collection system itself), a spark or ignition source can easily set off a dangerous combustible dust explosion. Batteries themselves create a ready ignition source; lithium-ion batteries, in particular, create a significant fire or explosion risk when damaged. Download the

Fire and explosion risks: Dust produced during battery recycling may be combustible. Carbon black, graphite, lithium salts and silicon powder, among other battery materials, are highly combustible under the right circumstances. Plastic dust created when crushing battery casings for Li-ion batteries can also be explosive. If clouds of dust are allowed to form within an enclosure (including the dust collection system itself), a spark or ignition source can easily set off a dangerous combustible dust explosion. Batteries themselves create a ready ignition source; lithium-ion batteries, in particular, create a significant fire or explosion risk when damaged. Download the