How Do Combustible Dust Explosions Happen?

Without adequate dust control, many fabrication shops are at high risk for dust explosions. Is your manufacturing facility at risk? Due to the nature of metalworking dust particulates and the many sources of sparks and heat in the fabrication process, the answer is probably "yes." The key is knowing the combustibility of the dust in your shop and understanding how dust explosions occur.

Welding, cutting and grinding all generate thousands of sparks an hour and it only takes one to ignite a dust explosion. Other processes, such as stamping and machining, may generate a lot of heat and friction that could become ignition sources. But how do you know just how combustible the dust is in your individual facility?

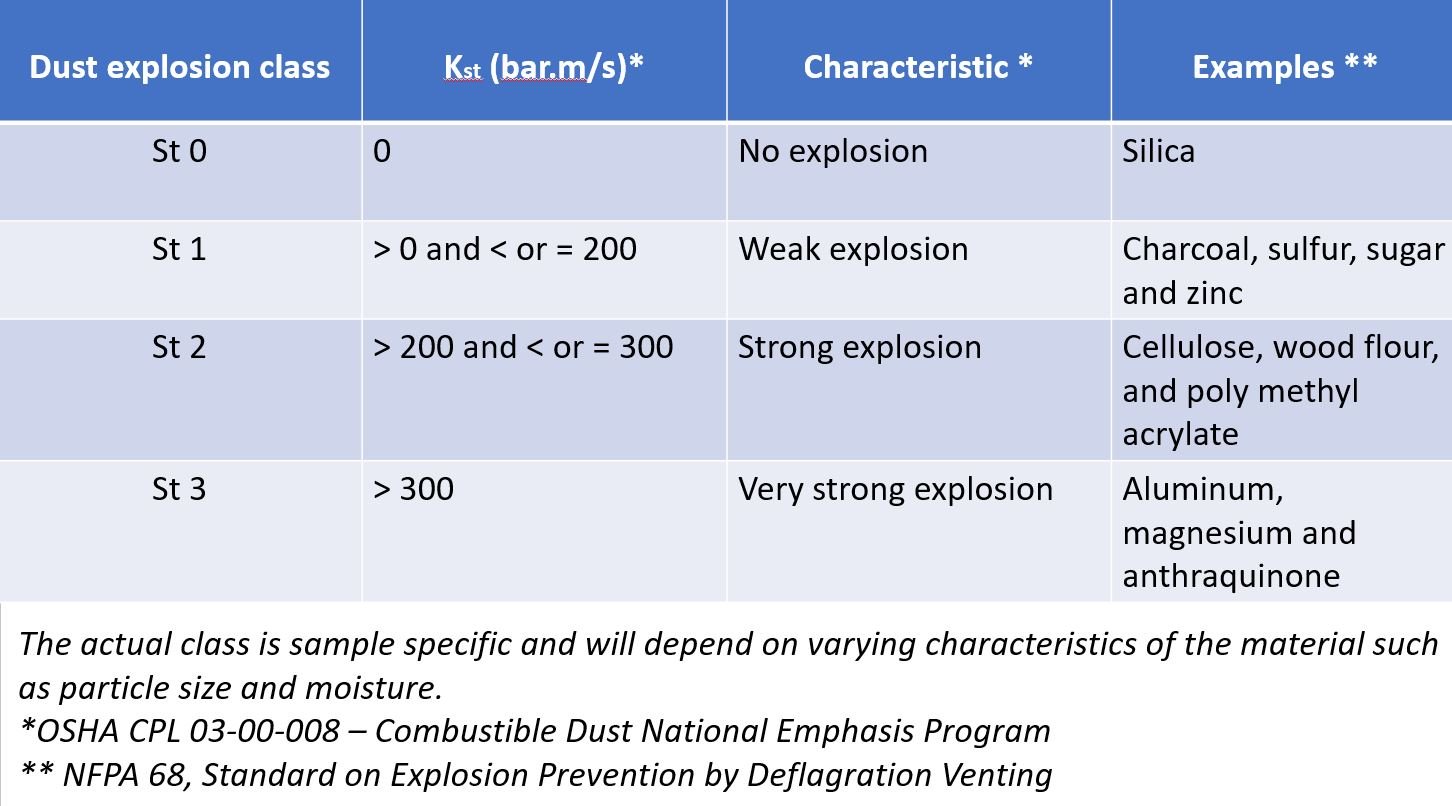

Dust explosions are classified by the Kst value into four potential classes: St 0, St 1, St 2 and St 3. Many metalworking dusts, including aluminum and most aluminum alloys, fall into Class 3, the most dangerous class of combustible dusts.

The second metric is the Pmax value, or the maximum pressure that could be produced by a dust cloud explosion. Together, Kst and Pmax values determine how much energy will be released in an explosion and how fast it will be released. The higher the Kst and Pmax values, the greater the potential for damage in the case of an explosion.

The Dust Explosion Pentagon

The Dust Explosion Pentagon

Once you know the combustibility of the dust in your facility, consider the "Dust Explosion Pentagon." Closely related to the more well-known "Fire Triangle," the Dust Explosion Pentagon is made up of five elements, all of which must be present before a dust explosion can occur.

Those elements are:

- Fuel: The fuel source for combustion is the dust itself.

- Oxygen: Fires and explosions require oxygen in addition to fuel; it is the interaction between the fuel source and oxygen in the air that supports combustion.

- Ignition: There must be an ignition source to start a fire or explosion. This is often a spark from fabrication processes, such as welding, cutting or grinding.

- Dispersion/concentration: Dust must be concentrated in the air at the right level to present an explosion hazard. If concentrations are too low (below the “lower explosion limit” for the dust type), there will not be enough dust in the air to support combustion at the rate required for an explosion. If concentrations are too high, there will not be enough oxygen in the air to support combustion.

- Containment: Containment prevents dust from dispersing and allows pressure to build up, increasing the likelihood of an explosion.

When dealing with combustible dusts, it is best to get expert guidance. Online resources from the Occupational Health and Safety Administration (OSHA) and the National Fire Prevention Association (NFPA), among others, will provide a general idea of the combustibility of different kinds of dusts. Also, a qualified air quality system engineer can help you evaluate your risks and make the right mitigation decisions for your facility. It's a small investment to make to protect your property and your employees.

Learn more about combustible dust explosions in this article printed in FABShop Magazine.

Contact Us With Your Questions!

SUBSCRIBE TO

BLOG UPDATES

The Dust Explosion Pentagon

The Dust Explosion Pentagon