Choosing The Best Fume Capture Solution For Manual Welding

Manual welders are in close proximity to and at risk of breathing hazardous fumed metals and metal oxides. To keep welders and those around them safe from the dangers of weld fumes, it’s critical to choose the right fume capture solution.

Considerations in Choosing a Weld Fume Capture Solution

With so many air filtration solutions available for welding, choosing the right one may be confusing. Here are some things to keep in mind during selection process:

With so many air filtration solutions available for welding, choosing the right one may be confusing. Here are some things to keep in mind during selection process:

- The welding process and fume volume

- Permissible exposure limits (PELs) for the specific type of weld smoke, as well as ACGIH and NIOSH recommended limits

- Whether welding applications are stationary or mobile

- Space availability for various fume extraction solutions

- The airflow necessary to effectively capture fumes

- Cost and maintenance requirements

Capturing welding fumes at the source is the most effective method of keeping welders safe. Source capture is the gold standard for weld fume mitigation and should be used wherever possible. Source capture solutions include fume arms, fume guns, backdraft plenums and welding tables with built-in fume extraction technology.

When source capture technology is not possible or practical, ambient air filtration systems can sometimes be used for weld smoke capture. Ambient systems may be more appropriate for light, occasional welding; they may not be effective in removing enough fume from the welder’s breathing zone to meet OSHA PELs. Ambient systems can also be used in tandem with source capture technology, ensuring that the fumes missed at the source will be filtered from the air throughout the facility by the ambient system.

Fume Extractors for Manual Welding

Manual welding that involves consumables, such as shielded metal arc welding (SMAW) and MIG/MAG welding, produce high levels of toxic fumes that must be pulled out of the breathing zone to protect the welder and others in the proximity at risk of exposure. Implementing a source capture solution is the most effective way of maintaining a safe breathing zone for welders. However, the type of welding and the area where welding occurs will dictate which source capture solution provides the best outcome.

Source capture technology involves three main components: the capture hood or plenum, a dust collector, and the ductwork connecting the two. The most effective method is to position the capture mechanism as close to the welding seam as possible without interrupting workflow or compromising the quality of the weld. Close capture will prevent the fumes from entering the breathing zone or collecting/building up in indoor environments. It is also the most energy efficient method of weld fume collection, as it minimizes the volume of air that must be moved.

Several factors dictate which source fume extraction solution will work best in manual welding applications. These include the size of the workpiece, the welder’s mobility requirements, the position of the welder, the type of welding technology being used, and the type of material being welded. The following technologies are among the most popular and effectively used for manual welding fume extraction.

Fume Arms

Fume arm pros

- Because the capture hood pulls the fumes directly from the source, it is highly efficient at preventing fumes from dispersing throughout the workplace.

- Its flexibility allows welders to make fine adjustments so the capture hood is always in the best possible position for extracting fumes.

- Requires less airflow than a backdraft plenum system often found on welding tables.

- Offers the versatility to attach to a stand-alone unit or be ducted to a centralized dust collection system.

Fume arm cons

- Fume arms are only effective if the capture hood is placed close to the weld seam.

- Welders must contain their welds to the maximum reach of the fume arm, which can range from 6 to 10 feet.

- Productivity can be hampered, as the welder must make frequent adjustments to ensure the capture hood is correctly positioned.

Top uses for fume arms

- General welding applications involving small to medium-sized tabletop parts.

Things to keep in mind

- To gain maximum capture, always ensure a proper distance is kept between the capture hood and the welding arc and that the hood is pointed directly toward the arc.

- Frequently clean the capture hood of dust and debris.

- Inspect for signs of wear or damage and make the necessary repairs or replacements.

- Check that the recommended airflow and suction are at optimal levels.

Fume Guns

A fume extraction gun is a welding tip extraction solution fixed at the nozzle of the welding gun. It is often paired with a portable hi-vac extraction unit and is used for MIG welding only.

A fume extraction gun is a welding tip extraction solution fixed at the nozzle of the welding gun. It is often paired with a portable hi-vac extraction unit and is used for MIG welding only.

Fume gun pros

- Highly effective at capturing fumes (up to 90% or more) before they can enter the breathing zone of the welder or escape into ambient air.

- Easy to use with minimal adjustment on the part of the welder.

- Provides a high degree of flexibility and welder mobility for working on large weldments or in enclosed areas.

- Modern versions are lightweight and ergonomic, reducing fatigue and enhancing mobility for welders.

- Highly energy efficient; fume extraction is only on while the weld torch is on, and the close capture minimizes the amount of air that must be moved.

- Does not require permanent installation of backdraft plenums or weld booths; extraction always travels with the welder.

Fume gun cons

- Line-of-sight issues can arise in certain welding positions, as the fume gun is attached directly to the torch.

- Some fume guns (especially older models) may be heavier or more unwieldy than a standard weld torch, leading to welder fatigue.

- Some weld smoke does escape, especially when working in an unusual position, such as welding upside down.

- Are not usable for some popular forms of welding, such as resistance welding.

Best uses for fume extraction guns

- MIG/MAG welding.

- Welders who require maximum mobility, particularly when welding large parts.

- Welders in enclosed spaces where other fume collection solutions cannot be used.

Things to keep in mind

- Use in well-ventilated areas with adequate airflow to minimize exposure risks from fume that escapes initial capture.

- Position the fume gun nozzle as close as possible to the welding arc, but without creating a line-of-site issue for the welder.

- Regularly inspect the fume gun for clogs, wear and tear.

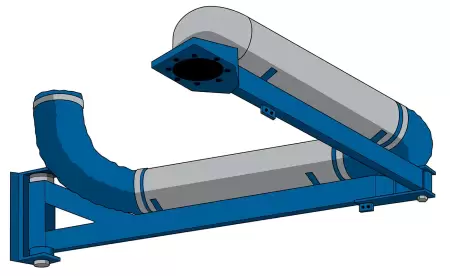

Backdraft Plenums

Whether ducted to a centralized collection system or integrated into a portable backdraft unit, backdraft plenums provide a continuous source of fume extraction for tabletop weldments. They are designed to pull fumes away from the breathing zone.

Whether ducted to a centralized collection system or integrated into a portable backdraft unit, backdraft plenums provide a continuous source of fume extraction for tabletop weldments. They are designed to pull fumes away from the breathing zone.

Backdraft plenum pros

- Unlike fume arms, they do not require repositioning on the part of the welder.

- Generally preferred over downdraft tables because weld fumes naturally rise, making capture more effective.

- Backdraft plenums are effective at pulling fumes away from the welder’s face, offering better visibility and improved weld fume safety.

Backdraft plenum cons

- Most backdraft plenums are stationary, restricting welder mobility and flexibility.

- Because the plenum is generally farther away from the part, a backdraft plenum may need to move more air and therefore use more energy compared to a close-capture method such as a fume arm or fume gun.

- Space requirements can limit the implementation of backdraft plenums.

- Some plenums can be noisy.

Best uses for backdraft plenums

- Welding of small- to medium-sized parts on a workbench.

- In high-volume work environments where the arc-on time can create higher concentration of fumes and continuous fume extraction is preferred.

Things to keep in mind

- Ensure the plenum is close enough to the weld fume source to achieve efficient capture, using ACGIH principles for fume extraction system design.

- Seal joints with the appropriate sealants and/or gaskets to prevent air leaks. Quality ductwork, hoods and installation will ensure the duct system is completely sealed, reducing any air noise.

- Test and adjust the placement of the plenum to ensure efficient capture.

Welding Tables with Fume Extraction

Manual welding on a welding table with a fume extraction offers an all-in-one welding booth solution for the safe removal of welding fumes, directly from the source. Welders simply place their material on the work surface, turn on the fume extraction and begin welding.

Manual welding on a welding table with a fume extraction offers an all-in-one welding booth solution for the safe removal of welding fumes, directly from the source. Welders simply place their material on the work surface, turn on the fume extraction and begin welding.

Welding table pros

- Welding tables, or backdraft tables, are easy to use, as the plenum is strategically placed to effectively capture fumes and there is no adjustment required of the welder.

- There is no need for a separate dust collector or ductwork when utilizing an all-in-one table with fume extraction, which saves on space and costs.

- These highly versatile weld fume tables can be used for most tabletop manual welding applications.

- Installing a welding bench is easy, as they are typically sold as a “plug-and-play” solution.

Welding table cons

- Weldments that are too large or too heavy to be placed on the table will require a different fume extraction solution.

- Welders requiring a high degree of mobility to effectively weld a part will encounter limitations with a welding table.

The best uses for welding tables with fume extraction

- Stationary tabletop welding applications for small to medium-size weldments.

- Smaller fabrication shops where the backdraft tables can support the needs of a handful of manual welders.

- Welding schools with multiple stationary weld booths

Things to keep in mind

- Regularly inspect and clean the fume extraction system for optimal performance. This includes replacing filters and servicing fans and motors as needed.

- Adjust the airflow rate based on the intensity of the welding process and type of material being welded.

- Monitor air quality to ensure capture settings are correct.

What About Downdraft Tables?

Downdraft tables are effective at capturing heavy particulate from manual cutting, grinding and metalworking. They feature a steel bar grated worksurface and are built in a plug-and-play configuration with a built-in filtration system. They pull contaminants down and away from the worker.

Downdraft tables are effective at capturing heavy particulate from manual cutting, grinding and metalworking. They feature a steel bar grated worksurface and are built in a plug-and-play configuration with a built-in filtration system. They pull contaminants down and away from the worker.

Downdraft tables are sometimes used for light welding applications, but they are not typically recommended as a primary source capture solution for weld fume, especially for high-production environments. Because welding fumes rise up from the weldment, the downdraft table is not effective at preventing the fumes from entering the breathing zone. In addition, a downdraft table may pull air away from the welding torch, stripping some of the shielding gasses. For most welding applications, backdraft fume extraction solution is preferred.

Ambient Fume Extraction for Welding

Rather than capturing fumes directly from the source, ambient fume extraction systems clean contaminants from the air for the whole facility. They are similar to a general exhaust ventilation system but include filters for removing contaminants. They can also be used as a secondary control strategy, collecting contaminants that escaped the primary fume extraction system (fume arms, fume guns, welding tables, etc.).

The ambient system can be designed in a “push-pull” configuration where a series of ducts move air in a linear pattern near the ceiling; in a circular configuration where a series of floor-mounted dust collectors with directional intake and exhaust plenums positioned to create a circular airflow pattern; or with an overhead capture design where a large stationary capture hood is placed over welding stations and the fumes are captured as the rise.

Ambient fume extraction tips/best practices

- When using an ambient fume extraction system for manual welding, it is important to design the system to capture contaminants and keep them out of the breathing zone.

- Reduce energy costs and pressure on the HVAC system by utilizing an ambient air filtration system that returns the clean air back into the facility instead of exhausting it outdoors.

- Make sure the air change rate (air changes per hour) is sufficient to keep contaminant concentrations below the PEL. The air change rate will depend on numerous factors, including volume of weld fume produced and room size and configuration; rates should be set according to ACGIH principles for industrial ventilation.

- Ambient air filtration will typically use more energy than source capture solutions, as air must be moved for the whole facility instead of just a small area.

Safe Solutions for Manual Welding

Implementing the most effective solution for managing manual weld fumes accomplishes goals related to protecting the health of workers and staying in compliance with OSHA PELs for weld fume exposure. And while worker safety and avoiding fines are top priorities, cleaner workspaces are also more productive workspaces. Whether it’s a portable extraction unit supporting a single welder or a large centralized system ducted to multiple welding stations throughout the facility, there is a solution available that will cover all your needs.

Finding the right fume extraction system is also about making a long-term investment in growth and sustainability. For more information about selecting a system that will capture your manual welding fumes, contact the experts at RoboVent.

Contact Us With Your Questions!

SUBSCRIBE TO

BLOG UPDATES