Industrial Cartridge Filters: Major Types and Configurations

Dust collector cartridge filters come in a variety of sizes, configurations and media types. Understanding the various options for industrial cartridge filters will help you choose the right filter for your cartridge dust collector.

Want to learn more? Download the Cartridge Filters Buyer’s Guide.

Parts of a Cartridge Air Filter

A dust collector cartridge filter is designed to capture and retain fine particulate matter from the airstream, ensuring cleaner air discharge and compliance with worker health and safety and environmental regulations. Here’s a breakdown of the basic parts and components of a dust collector cartridge filter.

Filter Media

This is the primary component of the cartridge filter responsible for trapping dust particles. Depending on the application, the media can be made from various materials, including cellulose, synthetic fibers, nanofibers, or even treated with a polytetrafluoroethylene (PTFE) membrane for added efficiency and resistance.

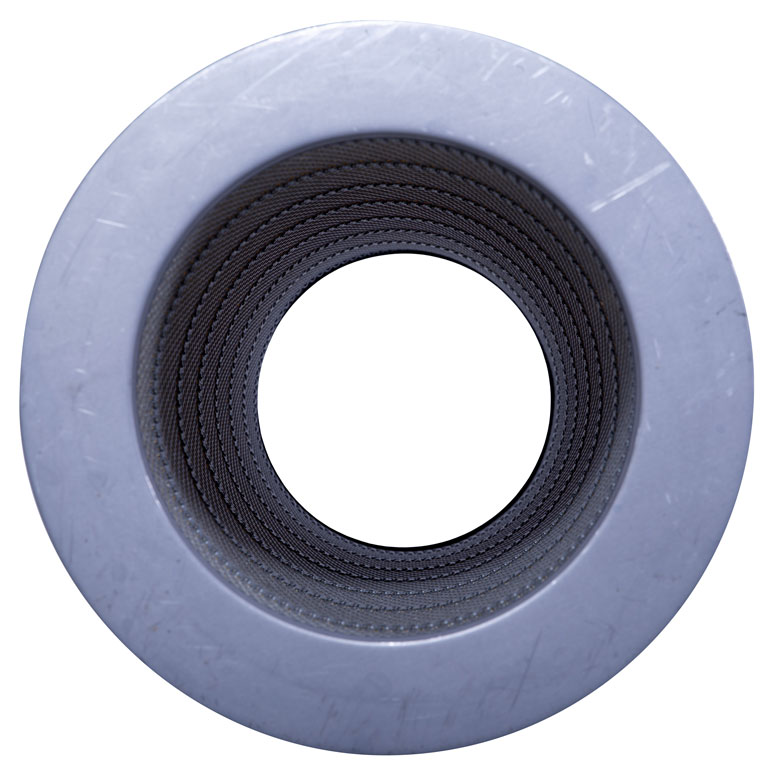

Pleats

Pleats

The filter media for cartridge air filters is usually pleated, increasing its surface area. The pleats facilitate more efficient dust capture while allowing optimal airflow through the filter. Pleat design and spacing have a large impact on the overall efficiency of the air filter.

Core/Inner Cage

This is the central structure that supports the filter media. It provides rigidity to the cartridge, preventing the filter from collapsing due to the differential pressure across it. The core can be made from materials like metal or plastic and usually features a perforated design for airflow.

End Caps

These are located at both ends of the cartridge cylinder. They provide a seal, ensuring that air passes through the filter media and not around it. One end usually has a hole or connection point to fit into the dust collector system, while the other end might be sealed or open, depending on the design.

Gasket/Seal

This is a soft material located on one or both end caps. The gasket ensures an airtight seal when the filter cartridge is installed, preventing any unfiltered air or dust from bypassing the filter.

Outer Liner or Mesh

Some cartridge air filters have an outer liner or mesh, which provides additional support to the filter media, especially during the filter pulse cleaning process. It also serves as a protective layer against any large or abrasive particles.

Types and Configurations of Dust Collector Cartridge Filters

Different dust collectors have different shapes and configurations. It is important to choose an industrial cartridge filter that has been made to fit your specific dust collector. Here are some different cartridge air filter configurations you may run into.

Download Replacement Filter Cross Sheet

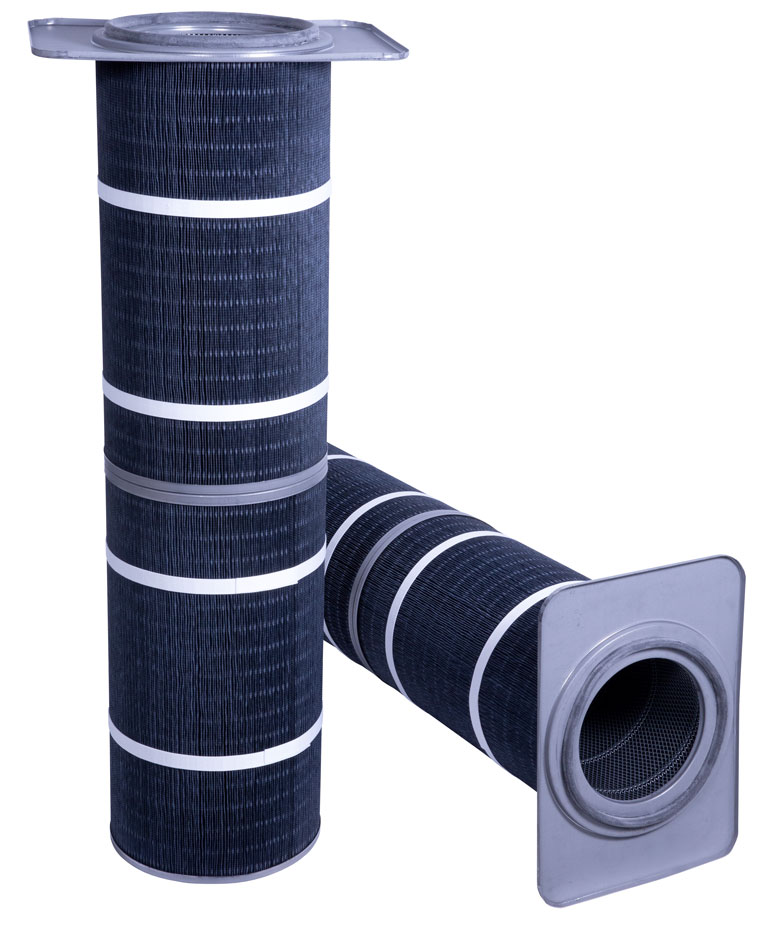

Cartridge Shape

Cartridge Shape

- Standard Cylindrical Filters: This is the most common type of industrial cartridge filter, characterized by its straight cylindrical shape. Provides a large surface area due to its extended length. Suitable for a broad range of applications and is often used in both small and large dust collection systems.

- Conical or Tapered Filters: These filters have a design that tapers from a larger diameter at one end to a smaller diameter at the other. The conical shape can increase the filter’s airflow capacity and facilitate better pulse cleaning in some systems. They may provide better dust release during cleaning due to their shape.

- Oval or Elliptical Filters: Instead of a perfect circle in cross-section, these filters have an oval or elliptical shape. This design can be advantageous in systems with limited space, as they can sometimes provide more filtration surface area than a round filter in the same footprint.

Cartridge Filter End Cap Configurations

- Open/Open Ends: Both ends of the cartridge are open, allowing for air to flow through the entire length.

- Open/Closed Ends: One end of the cartridge is open, while the other is closed. This configuration can be useful for directing airflow in a specific direction or manner.

- Single Open End (SOE) with Threaded Base: Some filters have a threaded base at the open end to screw into or securely attach to the system.

Media Types for Industrial Cartridge Air Filters

Dust collector cartridge filters come in a variety of media types. While shape and end cap configuration will be dictated by the make and model of the cartridge dust collector, the filter media type is chosen based on the characteristics of the dust you are collecting.

View our cartridge filter catalog.

Media Options for Cartridge Filters

- Cellulose: Cellulose media is derived from wood pulp and serves as a foundational filter material for many industrial applications. Its natural origin provides an affordable and effective solution for capturing larger dust particles, although it might be susceptible to moisture.

- Cellulose-Polyester Blend: By integrating synthetic polyester fibers with traditional cellulose, this blend strikes a balance between the affordability of cellulose and the moisture resistance of polyester. The combination also provides enhanced durability and potentially increased filtration efficiency.

- Spunbond Polyester: Crafted from continuous polyester fibers arranged in a web-like structure, spunbond polyester is known for its remarkable durability and resistance to abrasion. Its robust nature makes it an excellent choice for applications where filters face challenging conditions. Some polyester cartridge filters are also washable (a limited number of times).

- Nanofiber: Layering ultra-fine fibers over a base media, nanofiber filters are adept at capturing even submicron particles. The surface-oriented filtration approach ensures that particles are captured on the surface, making pulse cleaning more effective and extending the filter’s life.

- PTFE-Coated: Filters with a PTFE (polytetrafluoroethylene) coating offer superior particle capture efficiency, particularly for minute particles. This thin layer also provides exceptional resistance to moisture and a wide array of chemicals, making it a versatile choice for challenging environments.

- Oleophobic: Designed specifically to repel oil-based contaminants, oleophobic media ensures consistent airflow and filtration efficiency even in the presence of oily mists or aerosols. This trait is invaluable in industries where lubricants, coolants, or other oil-based substances are prevalent.

- Anti-Static: For environments where dust particles might generate a static charge—potentially endangering equipment or posing ignition risks—anti-static media is a must. It’s specially treated to dissipate static electricity, ensuring both safety and equipment functionality.

- Flame Retardant: Tailored for applications with potential fire hazards or where sparks might be present, flame-retardant media is chemically treated to reduce its flammability. It offers an added layer of safety, ensuring that the filter doesn’t become a combustion source.

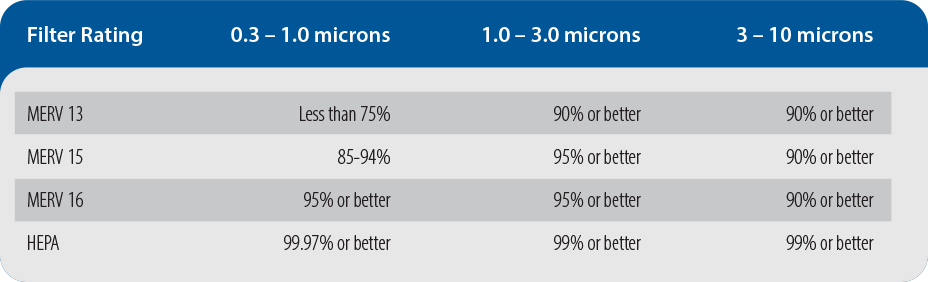

MERV Ratings for Cartridge Filters

Most industrial cartridge filters have a MERV rating between 10 and 16. The MERV rating is an indicator of filtration efficiency, or how efficiently the media can filter out particles in different size ranges. Filters with a higher MERV rating do a better job of removing smaller, even submicron, particulate. For applications requiring filtration efficiency higher than MERV 16 or that include gaseous or vapor emissions, a HEPA or activated carbon after-filter may be installed after the cartridge filters. (Note: Industrial cartridge filters will all approach a MERV rating of 16 once they build up a dust cake. However, if you are filtering submicron particulate that is toxic or hazardous, or require high levels of cleanliness in the production environment, it is important to select a filter that will provide high filtration efficiency across the entire filter life.) Here are some general guidelines for MERV ratings for cartridge air filters.

Most industrial cartridge filters have a MERV rating between 10 and 16. The MERV rating is an indicator of filtration efficiency, or how efficiently the media can filter out particles in different size ranges. Filters with a higher MERV rating do a better job of removing smaller, even submicron, particulate. For applications requiring filtration efficiency higher than MERV 16 or that include gaseous or vapor emissions, a HEPA or activated carbon after-filter may be installed after the cartridge filters. (Note: Industrial cartridge filters will all approach a MERV rating of 16 once they build up a dust cake. However, if you are filtering submicron particulate that is toxic or hazardous, or require high levels of cleanliness in the production environment, it is important to select a filter that will provide high filtration efficiency across the entire filter life.) Here are some general guidelines for MERV ratings for cartridge air filters.

- MERV 10-13: Use these basic cartridge air filters for larger and less toxic particles, such as sawdust, larger mineral particles, and general atmospheric dust from manufacturing plants.

- MERV 14-16: Cartridge filters with high filtration efficiency are used for smaller/submicron particulate or fumes, such as mild steel weld fume, fine metal dust from grinding operations, or certain chemical powders in manufacturing.

- HEPA After-Filter: A HEPA-after filter may be recommended for highly toxic/hazardous submicron particulate, such as stainless steel weld fume, certain chemical or pharmaceutical applications, and nanomaterial collection.

- Activated Carbon After-Filter: Molecular filtration, such as an activated carbon after-filter, is used for gas-phase emissions, odor control, volatile organic compounds (VOCs), chemical vapors or aerosols.

Choosing the Best Industrial Cartridge Filter for Your Application

The best filter cartridge for your industrial air filtration applications depends on the dust and application characteristics as well as your indoor air quality requirements. Here are some things to consider in cartridge filter selection.

- Nature of the Dust: The type of dust (wood, metal, organic, etc.) can dictate the filter choice. Some dust types might be abrasive, sticky, or even reactive with certain filter materials.

- Particle Size: The size of the particles you aim to capture will determine the efficiency and type of filter you need.

- Air Volume and Velocity: Ensure the chosen filter can handle the airflow volume and velocity of your system.

- Operating Conditions: Consider factors like temperature, humidity, and chemical exposure, as they can influence filter performance and longevity.

Find your industry or application to learn more.

Need help choosing the right cartridge air filter?

RoboVent manufactures high-quality dust collector cartridge filters for virtually any make and model of cartridge dust collector. We can help you choose the best cartridge filter for your application—and even manufacture custom aftermarket replacement filters to suit your needs.

Contact Us With Your Questions!

SUBSCRIBE TO

BLOG UPDATES