Complete Guide to Dust Control in Battery Manufacturing

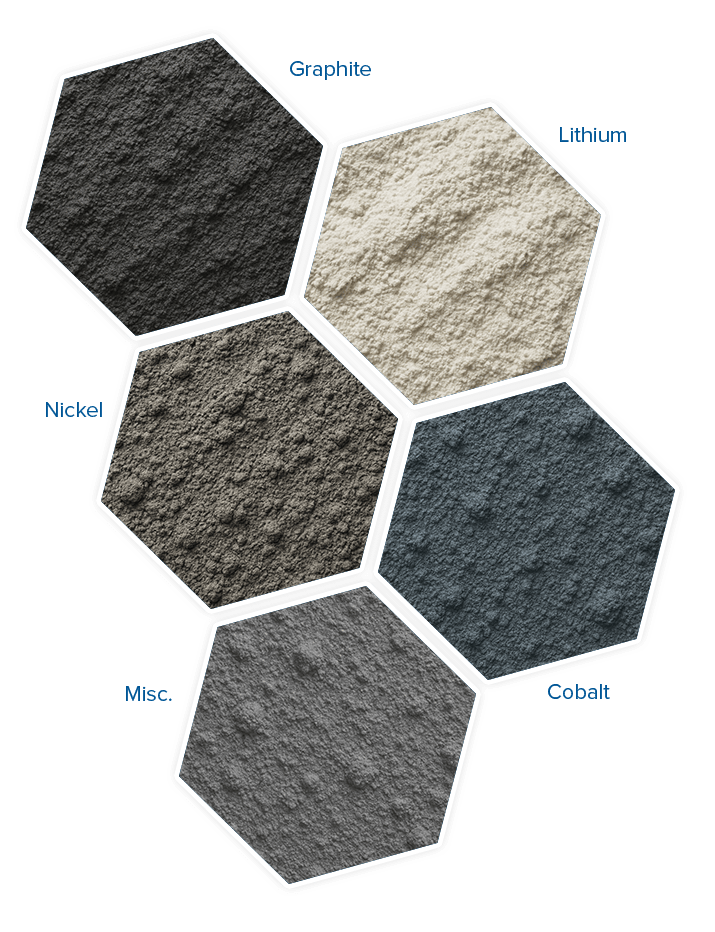

As electric vehicle (EV) demand surges, battery manufacturers face a growing challenge: battery dust from production processes. Fine particles from graphite, lithium, nickel, cobalt, and other cathode and anode materials pose serious risks to worker safety, product integrity and regulatory compliance.

This guide will walk you through the most critical dust control challenges in battery production and the best practices for solving them. Whether you’re working to meet cleanroom standards or reduce your explosion risk, effective dust management is essential for a safe, efficient battery production facility.

Your Guide to Battery Manufacturing Safety: What's Inside

This guide to dust collection for battery manufacturing takes a deep dive into the real-world challenges of dust control in EV battery manufacturing and the practical strategies top manufacturers are using to solve them. Whether you’re building a new facility or improving an existing one, this guide offers clear, actionable insights to help you protect your workers, improve your product, and keep your operations running smoothly.

Inside, you'll discover:

Where dust comes from at each stage of the battery fabrication process — and why different dust types require different control methods

The hidden dangers of common materials like lithium, graphite, nickel, and cobalt — including respiratory hazards, contamination risks, and combustible dust concerns

Cleanroom and air quality standards that apply to modern battery production, and what it takes to stay in compliance

How to design an effective dust collection system, including capture points, filtration, ventilation, and explosion protection

What leading battery manufacturers are doing today to manage dust safely and efficiently — and what’s coming next

Understanding Dust Types in EV Battery Manufacturing

Lithium-ion battery production generates a variety of fine, often hazardous particulates. The specific dust types produced depend on the materials and processes used — and each presents distinct challenges for containment, filtration, and safety. Common dust types include:

Graphite dust: Highly combustible and easily dispersed; a primary concern for explosion risk

Lithium dust: Typically in the form of lithium salts (e.g., lithium carbonate, lithium hydroxide); can be chemically reactive or corrosive, and may irritate skin, eyes, or lungs when airborne

Nickel and cobalt dust: Toxic heavy metals; long-term exposure may cause respiratory and systemic health issues

Other conductive or metallic particles– Can interfere with sensitive electronics and degrade product quality if not contained

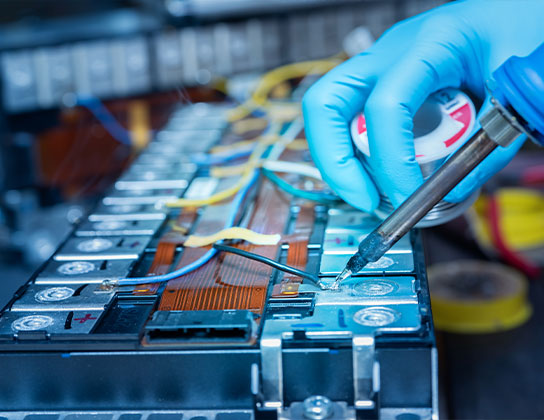

Dust is released throughout the manufacturing process, including powder mixing, drying, calendaring, cutting, welding, and cell assembly. Without targeted source capture and proper ventilation, these particulates can accumulate in the air and on surfaces, increasing the risk of exposure, contamination, or ignition.

Challenges of Dust in Battery Manufacturing

Dust in lithium-ion battery production presents serious risks that span health, safety, and product quality. Addressing these risks requires a proactive, facility-wide approach to dust control.

Worker Health and Safety

Many materials used in battery manufacturing — including nickel, cobalt, and lithium — produce fine dusts that are hazardous when inhaled or absorbed through the skin. Chronic exposure can lead to respiratory disease, skin irritation, or systemic toxicity. Effective source capture and filtration systems are essential to protect workers and comply with occupational exposure limits.

Product Quality and Performance

Airborne particulates can contaminate sensitive materials and components during electrode fabrication and cell assembly. Even trace amounts of dust can interfere with electrochemical processes, reduce battery performance, and increase defect rates. Maintaining clean production environments is critical to ensuring product reliability and yield.

Combustion and Explosion Risk

Certain battery dust types — particularly graphite, carbon black, and fine metal particles — are combustible and can ignite under the right conditions. If these materials accumulate or become suspended in air, they may form explosive dust clouds that pose a serious hazard to equipment and personnel. Mitigating this risk requires compliant system design with explosion protection measures in place.

Best Practices for Dust Control in Battery Manufacturing

There’s no one-size-fits-all solution for dust control in battery manufacturing. Each facility — and each process within it — presents unique challenges that demand tailored strategies. From dry powder mixing to electrode cutting and cell assembly, every stage must be evaluated for its dust generation profile, material risks, and environmental requirements.

Effective dust control means making informed choices about:

- Dust collector type (e.g., cartridge vs. baghouse systems)

- Filtration media and efficiency

- Source capture vs. ambient air systems

- Containment and enclosure types

- Clean room standards for batteries

These choices aren’t just technical — they’re also regulatory. Battery production facilities must comply with OSHA exposure limits for toxic dusts like nickel and cobalt, as well as NFPA standards governing combustible dust safety and explosion protection. In cleanroom environments, battery dust control systems must also meet stringent air cleanliness and humidity standards to avoid contamination and ensure product performance.

This guide explores how to align your dust control strategy with both your production goals and compliance obligations. You'll gain insights into system design considerations, facility planning, and how leading manufacturers are adapting to evolving safety and quality demands — without compromising efficiency.

Ready to Learn More About Battery Manufacturing?

Talk to the Experts at RoboVent for Industrial Dust Control Solutions

If you're facing dust challenges in your battery manufacturing plant, consult with RoboVent experts. We understand the unique dust-related issues impacting production environments and worker health. Our team specializes in designing dust collection systems that meet safety standards for dust collection in battery manufacturing.

RoboVent's engineers collaborate with you to understand your facility's intricacies and the dust types generated during battery manufacturing. We focus on crafting customized industrial dust collection solutions that enhance productivity while ensuring safety compliance. Trust RoboVent to equip your facility with effective dust management systems that protect employees and optimize manufacturing processes.

Frequently Asked Questions

Battery

What is the importance of dust collection in battery manufacturing?

Dust collection for battery manufacturing is essential for maintaining a safe, clean, and compliant production environment. Materials like graphite dust, lithium dust, nickel, and cobalt generate fine particulates that can pose serious health risks, contaminate products, and create fire or explosion hazards if left unmanaged. An effective dust collection strategy helps manufacturers protect their workforce, maintain product integrity, extend equipment life, and meet OSHA and NFPA regulatory requirements.

How does dust affect battery production processes?

Dust impacts nearly every stage of battery manufacturing. Battery dust released during mixing, drying, coating, and assembly can interfere with electrochemical performance, damage sensitive components, and contaminate clean production zones. If not properly captured, dust can also build up on machinery and sensors, leading to premature wear, unplanned downtime, and inconsistent product quality. Precision processes demand precise air quality control and battery production dust management.

How does dust from manufacturing processes impact battery quality and performance?

Even small amounts of airborne dust can cause significant quality issues. Conductive or reactive dusts — such as graphite or lithium — may trigger internal short circuits or alter chemical reactions inside the cell. This can result in reduced capacity, shorter cycle life, increased defect rates, and in some cases, battery failure. Effective dust control is vital to meet the performance standards required for EV and energy storage applications.

Does my dust collection system need explosion prevention in battery manufacturing?

In most cases, yes — especially if you're working with combustible materials like graphite, carbon black, or aluminum powder. These dusts can ignite when suspended in air and exposed to heat, static discharge, or friction. If your process involves combustible dust in sufficient quantities, NFPA standards (including NFPA 660, NFPA 68 and NFPA 69) require specific explosion protection measures. These may include explosion vents, isolation valves, chemical suppression systems, and proper electrical grounding. Your dust collection system must be designed not only for capture efficiency, but also for compliance with these safety standards.

Additional Resources

https://www.robovent.com/a-visual-guide-to-combustible-dust-collection/

https://www.robovent.com/industrial-dust-collection/dust-collection-for-battery-manufacturing/

https://www.robovent.com/dust-collection/lithium-ion-battery-dust-collection/

https://www.robovent.com/dust-collection/nanomaterials-dust-collection/

https://www.robovent.com/applications/battery-material-handling-and-processing-dust-collection/

https://www.robovent.com/applications/battery-electrode-dust-collection/

https://www.robovent.com/applications/battery-cell-assembly-dust-collection/

https://www.robovent.com/applications/battery-cell-finishing-dust-control/

https://www.robovent.com/applications/battery-recycling-dust-collection/

Ready to grow your business?

Contact us and a member of our team will reach out soon.