Dust Problems in Battery Finishing

Battery finishing processes such as roll pressing, formation, degassing, aging, and EOL testing do not, themselves, generate much (if any) manufacturing dust. However, it is important to ensure that the environment in which battery finishing takes place is clean and free from dust created by other stages of the manufacturing process. The cell finishing stages are typically performed in a clean room environment with controlled temperature, humidity, and air quality. A holistic dust control solution that looks at how dust is created and how it moves through the entire manufacturing process will ensure that particulate is not allowed to build up in clean manufacturing environments.

Health and Safety Risks in Battery Cell Finishing

Regulations for the Battery Industry

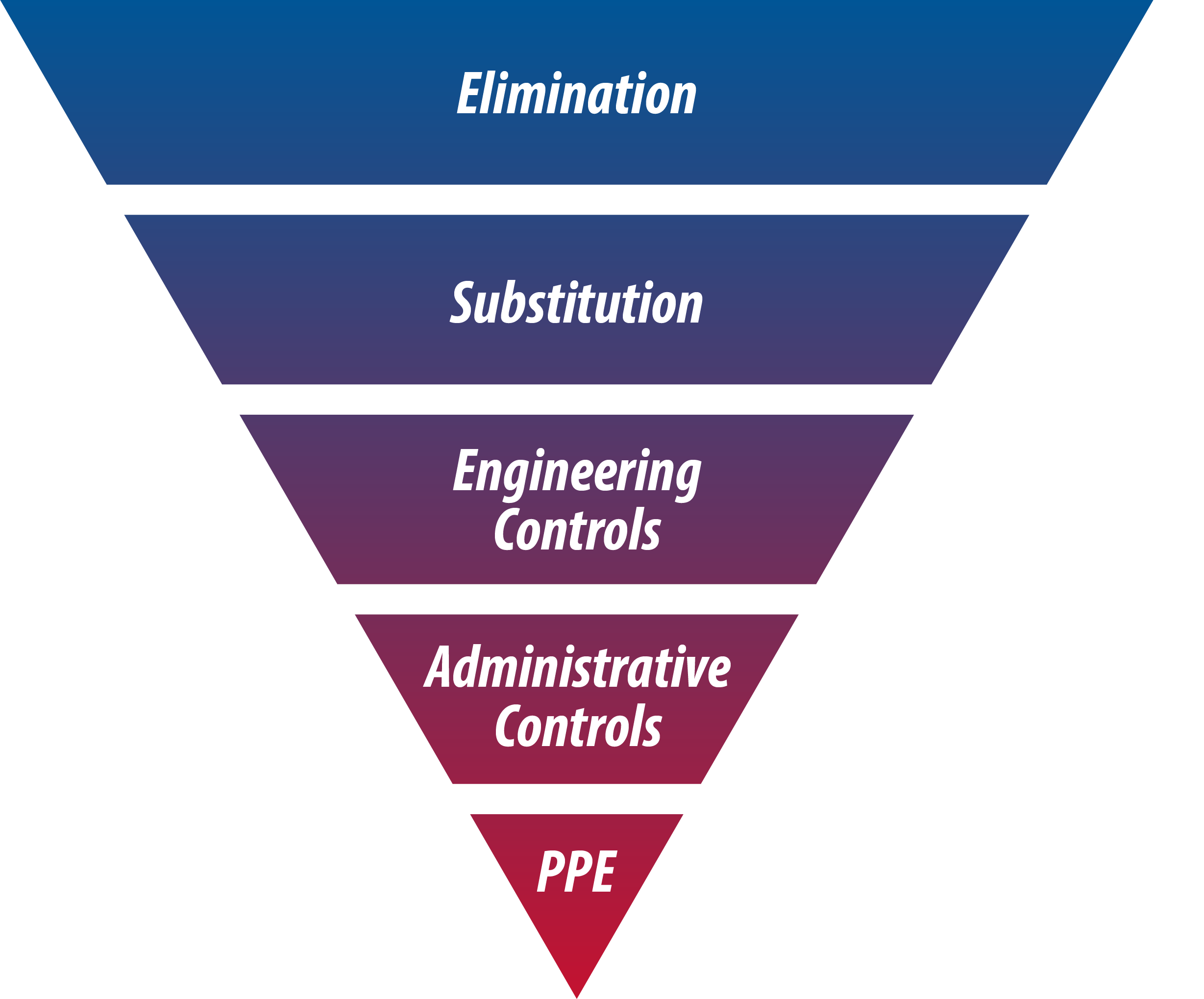

Battery manufacturers must comply with all environmental, worker health and safety regulations at all stages of the production process, including cell finishing. While cell finishing processes may not, by themselves, create large volumes of hazardous dust and emissions, it is still essential to ensure that all battery manufacturing processes meet regulatory standards related to worker exposure, combustible dust safety, and environmental protection. Relevant regulations for the battery industry include:

Dust Control Challenges for Battery Cell Finishing

The primary challenge in dust control for battery cell finishing is ensuring that the environment is clean enough and is not contaminated by fugitive dust and fume from other stages of the battery manufacturing process. Battery components—particularly the electrodes, separator, and electrolyte—are highly sensitive to contamination. Fugitive dust in the manufacturing environment can negatively impact battery reliability, performance and safety. For this reason, cleanroom or near-cleanroom conditions may need to be maintained at this stage of the process.

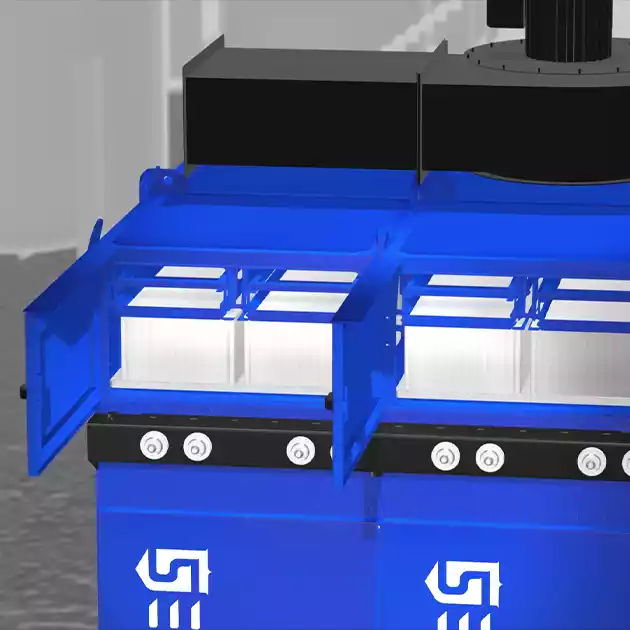

RECOMMENDED SOLUTIONS

OTHER SOLUTIONS

TOTAL FILTRATION PARTNER

RoboVent is your full turnkey resource for clean air in industrial environments. From facility testing and engineering, to installing equipment, providing replacement filters and preventive maintenance, RoboVent is ready to manage the whole process.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.

Exposure to hazardous chemicals such as solvents, acids and other chemicals used in the electrolyte solution. Workers may be exposed to these chemicals through inhalation or skin contact, which can lead to health effects such as respiratory irritation, skin irritation, and chemical burns.

Exposure to hazardous chemicals such as solvents, acids and other chemicals used in the electrolyte solution. Workers may be exposed to these chemicals through inhalation or skin contact, which can lead to health effects such as respiratory irritation, skin irritation, and chemical burns. Gases and vapors:

Gases and vapors: