FLEXTRAC™ - Robotic Welding Fume Extraction

CAPTURE ROBOTIC WELDING FUMES RIGHT AT THE SOURCE WITH ROBOVENT FLEXTRAC™.

Now, you can control robotic weld fumes at the source, with high-efficiency robotic tip extraction.

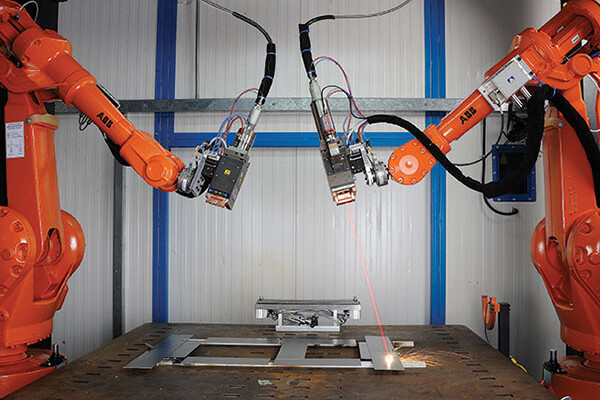

The RoboVent FlexTrac™ is the perfect solution for many robotic welding applications where hooded enclosures are not practical. The FlexTrac tip extraction hood collects the majority of weld fumes as they are created, reducing the need for large ventilation or ambient filtration systems in environments where robotic welding cannot be enclosed.

THE FLEXTRAC™ ENGINEERING PROCESS

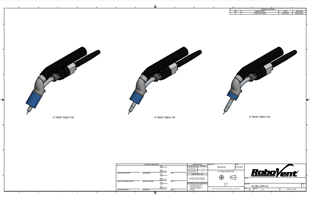

FlexTrac is not a one-size-fits-all solution. The Flex Trac hose and tip extraction hood must be custom designed and fitted for your application. Your RoboVent Solutions Engineer will work with you to evaluate your processes and design a FlexTrac system for your robot.

HOW IT WORKS

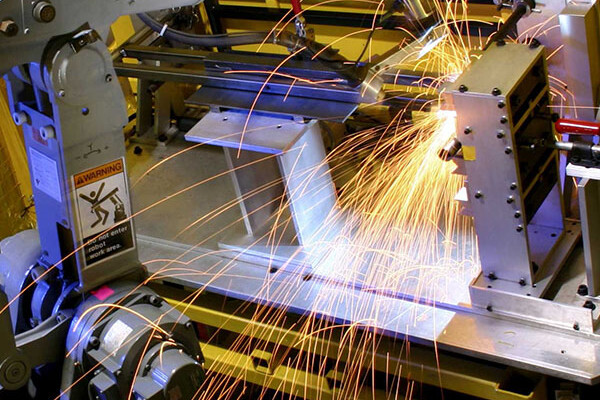

EXTRACTION TIP: The extraction tip is positioned right behind the weld torch on the robot arm. Depending on the application, the extractor tip captures 80-95% of weld fumes as they are created.

CUSTOM BRACKET: A custom bracket holds the tip in the correct position.

FLEXIBLE HOSE: A lightweight, flexible hose is connected to the extraction tip. The hose is attached to and moves with the robot arm.

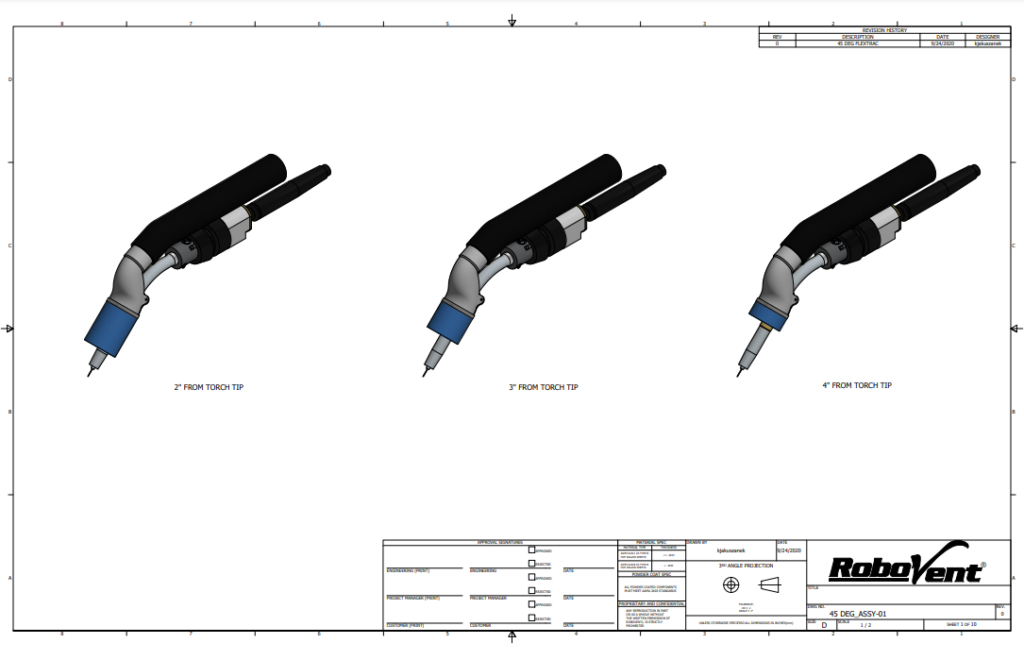

HIGH-VACUUM (HI-VAC) DUST COLLECTOR: The FlexTrac is attached to a high-vacuum (hi-vac) dust collector such as the RoboVent FlexPro™ or the RoboVent ProCube™.

FLEXTRAC™ INTERACTIVE GUIDE: IS FLEXTRAC RIGHT FOR MY PROCESS?

FlexTrac is an ideal solution for many robotic welding applications, but it isn’t right for everyone. FlexTrac works best when there is plenty of space to accommodate the hood and hose, the robot is not welding upside-down or in deep pockets, and there isn’t excessive movement during the welding process. Here are four questions to help you determine whether FlexTrac is right for your robotic welding process.

THE BENEFITS OF ROBOTIC TIP EXTRACTION

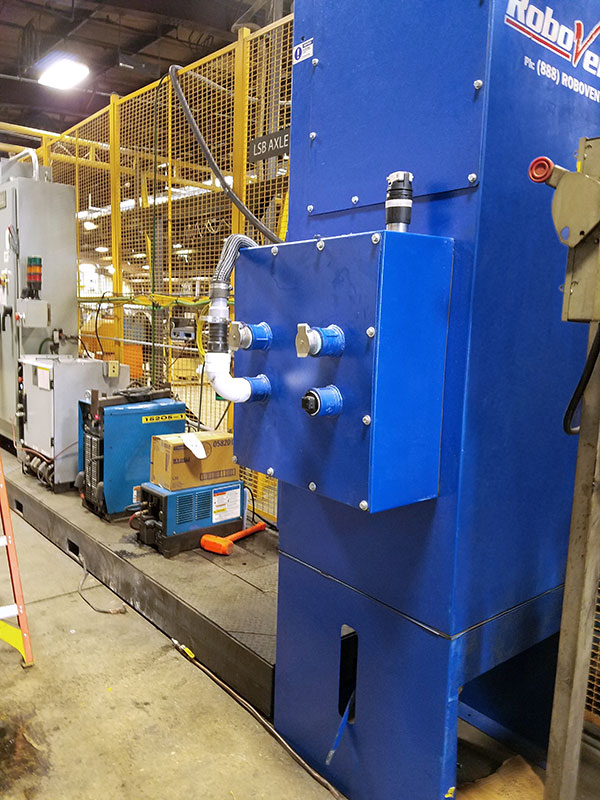

Robotic welders produce a high volume of toxic fumes due to arc-on times that far exceed manual welding. For this reason, robotic welding cells are traditionally enclosed under a hood that is ducted to a high–powered dust collector. When applications cannot be enclosed, fumes build up on the ambient air, creating health concerns for employees and putting facilities out of regulatory compliance.

Many companies have met these challenges with powerful ventilation systems or ambient filtration. While these systems work, cleaning the air for the entire facility requires movement of large volumes of air—meaning a more powerful, and more expensive, dust collection system. Exhaust ventilation systems also create energy concerns as heated or cooled air is vented to the outside and replaced with outdoor-temperature air.

FlexTrac is a more efficient way to collect weld fumes for MIG robotic welding applications. Source capture requires much less energy, since you are moving a much smaller volume of air. FlexTrac maximizes capture efficiency by positioning the extraction tip right on the robot arm. That means a smaller, more energy efficient high-vacuum dust collector can be used to capture the fumes. If ambient filtration is still needed, a much smaller system will generally suffice to clean up any remaining fumes.

FlexTrac can be used for robotic welding of tractor-trailers, agricultural equipment, large infrastructure components and other large weldments that are difficult or impossible to put under a hood. It also works well in environments where cranes and other overhead equipment make hooded enclosures impractical. Take the quiz to see if FlexTrac is right for you.

A CLEANER, SAFER FACILITY

FlexTrac gives manufacturers a new option to keep hard-to-manage weld fumes under control for high production robotic applications. As today’s air quality regulations become stricter, the filtration provided by FlexTrac can ensure that your facility remains compliant. Citations from the Occupational Safety and Health Administration (OSHA) can lead to major fines and other legal hassles.

Cleaner facilities are safer ones, as well. Robotic tip extraction offers more protection for workers, since most fumes are collected at the source before they escape into the ambient facility air. The FlexTrac keeps toxic weld fumes out of the air and prevents them from drifting throughout the facility, significantly reducing the need for ambient air quality control.

CONTACT US

Contact RoboVent today to start building your custom dust collection system.