DUST AND FUME COLLECTION CHALLENGES IN THE OIL & GAS MANUFACTURING INDUSTRY

Manufacturers producing equipment for the oil & gas industry face a number of challenges when it comes to indoor air quality.

Manufacturers producing equipment for the oil & gas industry face a number of challenges when it comes to indoor air quality.

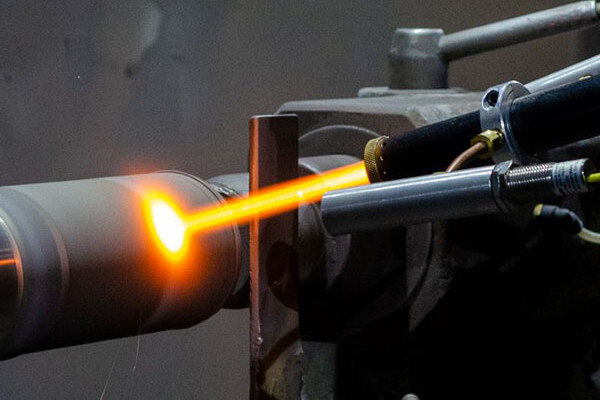

- Many components, including oil & gas pipeline infrastructure components, involve high-production manual or robotic welding. Welding of heavy equipment and pipelines produces toxic fumes that have significant impacts on worker health. The volume and composition of weld fumes produced by welding oil & gas equipment depends on the materials and processes used, but often includes toxic elements and compounds such as hexavalent chromium, manganese, nickel and beryllium. Stainless steel, which is commonly used for storage tanks, valves and other components, produces especially toxic fumes. If the fumes are not controlled, workers may suffer from a variety of health effects ranging from manganism to lung cancer.

- Cutting and grinding heavy steel produces high volumes of dust that are irritating the lungs, toxic when inhaled or ingested, and potentially damaging to other equipment and processes. This heavy dust can be challenging to contain and control.

- Because equipment used for oil & gas is often used in highly corrosive environments or must be left in the field for extended periods of time, corrosion resistance is of critical importance. However, the materials and coatings used to increase corrosion resistance often contain highly toxic elements such as cadmium, which makes working with the dust or fumes even more dangerous.

- A lot of the equipment and infrastructure components produced for the oil & gas industry are extremely large. They may be too large to be contained under a hood and often require the use of overhead cranes. These factors make source capture, which is usually the most economical and effective method of air quality control, challenging.

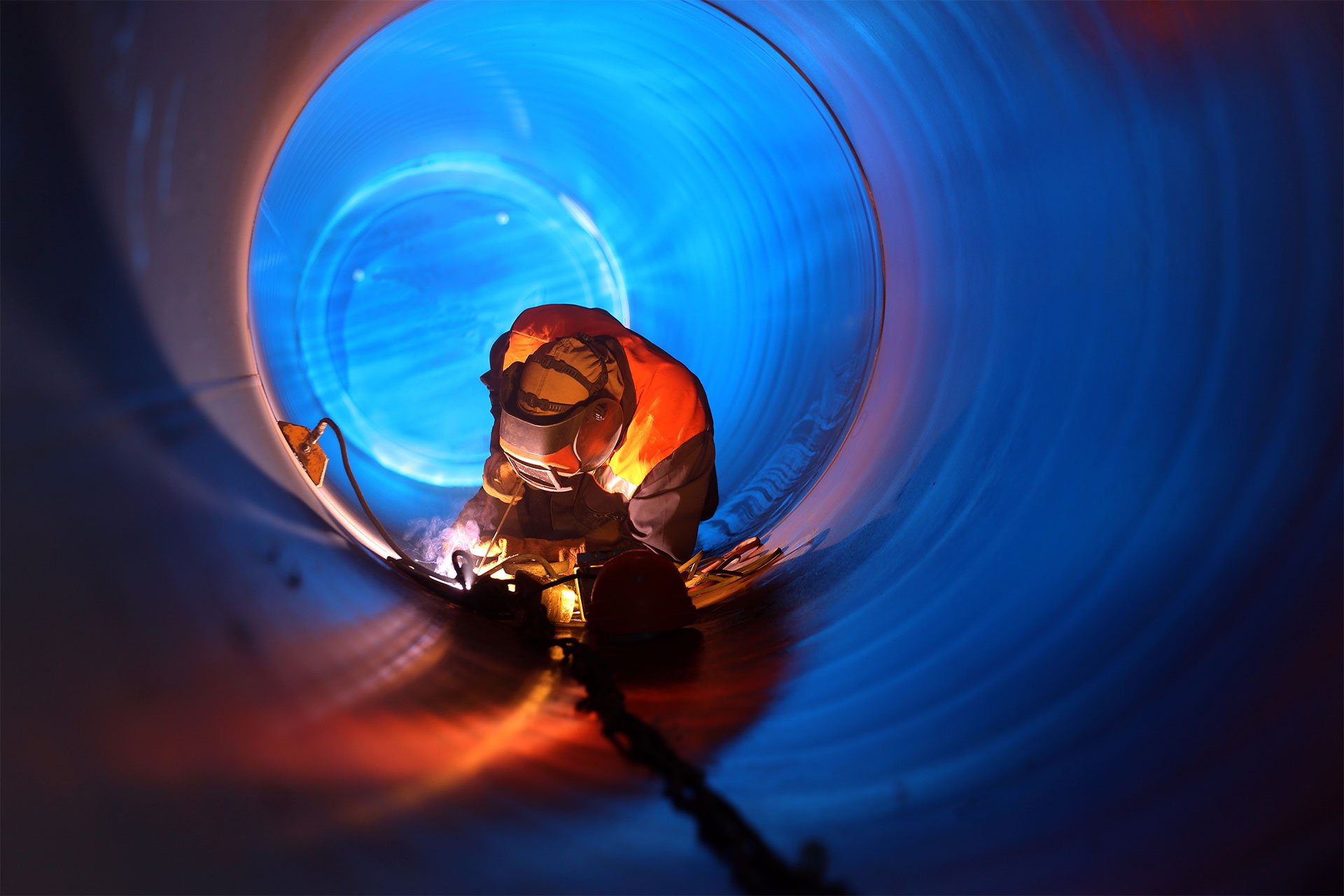

- Construction of storage tanks, ship hulls and tanker trucks often requires manual welders to work inside enclosed spaces where weld fumes can rapidly collect to dangerous levels. Controlling weld fumes inside an enclosed environment can be difficult, as most source capture methods will not provide adequate control.

OSHA requires manufacturers working in the oil & gas industry to maintain a safe and healthy working environment for all employees. They have set permissible exposure limits (PELs) for airborne contaminants. Most manufacturers producing equipment for the oil & gas industry in enclosed manufacturing environments will have to follow OSHA PELs for General Industry. Some subsets of the industry may fall under separate standards for Shipyards or Construction. Whatever the industry sector, failure to meet OSHA PELs can have significant legal and financial repercussions for manufacturers.

Many manufacturers in the oil & gas manufacturing industry are finding that meeting these minimum standards is no longer enough to remain competitive and attract skilled workers. The American Welding Society estimates that manufacturers will see a shortage of 290,000 skilled workers by 2020. Maintaining a pleasant and safe workplace will help manufacturers attract and keep the best workers.

In addition, following OSHA standards may not fully protect worker health. The American Conference of Governmental Industrial Hygienists (ACGIH) has developed voluntary guidelines for exposure to toxic airborne particulates based on the latest scientific evidence of harm. In most cases, these guidelines are lower than OSHA PELs.

Related Resources

SOLUTIONS FOR DUST AND FUMES IN THE OIL & GAS MANUFACTURING INDUSTRY

RoboVent knows how to control weld fumes and dust for manufacturers in the oil & gas industry. From pipeline production to drilling equipment manufacturing, we can help you analyze your processes, identify your challenges, and design an air quality solution that is tailored to your needs.

We have been an industry leader in clean air since 1989, and we are continually innovating to make our equipment safer, more effective, and more energy efficient. And RoboVent guarantees satisfaction. Our manufacturing standards are the highest in the industry, and our warranty is the best in the business.

We have a wide range of solutions for the oil & gas manufacturing industry.

- The Extractor™ Fume Gun is the perfect solution for manual welding of large infrastructure components or welding inside tanks or pressure vessels for the oil & gas industry. Pair it with the powerful, compact ProCube II Hi-Vac Dust Collector or the simple and lightweight Fume Eliminator™️ for a practical, portable solution for weld fume control.

- Our powerful Senturion®️ dust collectors can be ducted to multiple stations or weld cells to provide dust and fume collection for your entire manufacturing line.

- When source capture is not an option, we offer a variety of ducted, ductless and floor-mounted ambient air filtration options, including Vortex™.

For information on other industries RoboVent partners with, click here.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.