THE COMPLETE GUIDE TO WELDING

FUME EXTRACTION SYSTEMS:

HOW (AND WHY) TO KEEP YOUR FACILITY AIR CLEAN AND SAFE

CHAPTER FIVE: AMBIENT AIR FILTRATION SYSTEMS FOR WELD FUMES

Ambient air filtration may be used as a stand-alone weld fume solution where source capture is not possible or as part of a hybrid solution that includes both source capture and general/ambient filtration.

What is ambient air filtration?

Ambient air filtration cleans contaminants from the air for the whole facility. Unlike source capture systems, which capture contaminants directly at the source of emissions, ambient systems are set up to turn over and filter air for the entire room or facility. In this way an ambient filtration system is similar to a general exhaust ventilation system, with the addition of filters to remove contaminants from the air. Cleaned air may be exhausted to the outside or returned to the facility.

How is ambient air filtration used for weld fume control?

An ambient air filtration system may be used as a secondary control strategy to collect weld fume that escapes from the primary source capture system, or as a primary control strategy for the collection of weld fume from manual or robotic welding. Ambient air filtration may be used when:

- Source capture is not possible or practical due to the configuration of the facility or the processes being used (e.g., large robotic welders that cannot be contained under hoods, the use of overhead cranes and equipment, etc.).

- Weld fumes are minimal (e.g., for resistance welding).

- No humans are exposed to the weld fumes.

- Fugitive fume from source capture systems requires a secondary backup weld fume collection method.

What are the advantages and disadvantages of ambient air filtration vs. source capture?

Ambient air filtration eliminates the need for ductwork, enclosures or source capture hoods. It also minimizes interference with the shielding gases while welding. However, like general exhaust ventilation, ambient air filtration does not prevent weld fumes from entering the breathing zone and may not adequately protect welders from weld fume exposure. In addition, it requires turnover of large volumes of air, which can be very energy intensive. For these reasons, source capture is advised where possible.

Can you use ambient air filtration with manual welding?

It is possible to use ambient systems for manual welding in some circumstances. When designing an ambient system for manual welding or other environments where humans may be exposed to welding fumes, it is important to design the system to pull contaminants out of the breathing zone–for example, by pulling rising weld fume up and away from areas where people are working. Ambient air filtration for manual welding may be more appropriate for low-volume production environments with intermittent use of welding and for types of welding with lower emissions, such as resistance welding. However, source capture is generally the preferred method of weld fume extraction.

Which welding processes produce the most fumes?

In general, welding processes that use consumables–such as MIG (GMAW), TIG (GTAW), arc welding, stick welding, and flux-cored welding–produce more fumes than resistance welding or laser welding. Most of the weld fume comes from the welding consumable. However, that does not mean that resistance and laser welding do not produce fumes. These types of welding can produce dangerous emissions, especially when welding coated or galvanized metals. Learn more about the health risks of different types of welding:

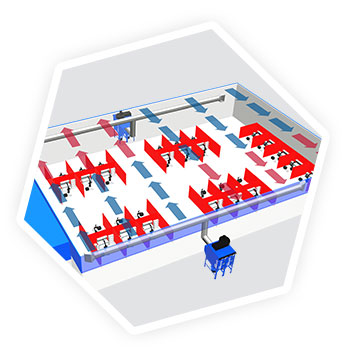

Push-Pull Configuration

This configuration uses a series of parallel ducts to move air in a linear pattern near the ceiling. This pattern can also be achieved with a series of ductless dust collectors mounted near the ceiling or on sidewalls. Welding fumes naturally rise as they are generated, allowing them to be captured by ceiling-mounted ducts or collectors.

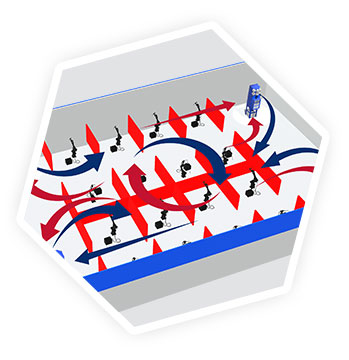

Circular Configuration

This method uses a series of floor-mounted dust collectors with directional intake and exhaust plenums that are positioned to create a circular airflow pattern.

Overhead Capture

A large stationary capture hood can be placed directly over the welding operation to capture fumes as they rise.

Can you use ambient air filtration with manual welding?

It is possible to use ambient systems for manual welding in some circumstances. When designing an ambient system for manual welding or other environments where humans may be exposed to welding fumes, it is important to design the system to pull contaminants out of the breathing zone–for example, by pulling rising weld fume up and away from areas where people are working. Ambient air filtration for manual welding may be more appropriate for low-volume production environments with intermittent use of welding and for types of welding with lower emissions, such as resistance welding. However, source capture is generally the preferred method of weld fume extraction.

How many air changes are required per hour for ambient air filtration systems in welding?

An ambient air filtration system turns over all of the air in the room or facility on a regular basis. There must be enough air changes per hour to remove contaminants as they are being generated and prevent buildup to undesired levels. Depending on the volume and type of contaminants present, this may require a minimum of 10 to 25 or more air changes per hour to maintain desired indoor air quality and meet regulatory requirements. The CFM requirements to achieve this rate of air turnover will depend on the total volume of air that must be moved.

Do ambient fume capture systems require ductwork?

An ambient fume capture system may be ducted or ductless. A ducted ambient fume capture system, such as a traditional push-pull ambient system, uses a series of ducts that pull dirty air in from one side and push clean air back in from the other. The ducts are usually connected to a single, large dust collector, often placed outside. These systems are typically placed near the ceiling to capture rising emissions. Ductless ambient fume capture systems use several smaller dust collectors placed inside the facility to create air flow patterns that pull dirty air away from workers and push clean air back in. A ductless ambient dust collector has intake and exhaust plenums, which may use adjustable louvers to direct airflow.

Can ambient and source capture weld fume collection systems be used together?

Yes! It is quite common to have a source capture system to collect the majority of the weld fume and a backup ambient system to collect fugitive fume. A secondary ambient system can be especially helpful to collect rising fume from cooling parts or fugitive fume missed by fume arms or backdraft plenums.

How are ambient fume capture systems designed?

Ambient fume capture systems must be designed to 1) maintain overall concentrations of indoor air contaminants within the Permissible Exposure Limits (PELs) for both total weld fume and individually regulated constituents, and 2) as much as possible, pull weld fume and other contaminants away from the breathing zone for workers. System design will depend on many factors, including the type and volume of emissions, where source points for emissions are located, existing airflow patterns within the building (e.g., from the HVAC system, ventilation fans, and building openings), the physical layout of the facility (room size, walls and partitions, enclosures, opening, etc.), and where people are working. For a large, complex installation, this can make ambient air filtration system design quite complicated. RoboVent’s VentMapping Engineering Process uses Computational Fluid Dynamics (CFD) and computer modeling to optimize ambient air quality system design. Not sure where to start? Learn More About RoboVent Facility Testing and Engineering Services.

TALK TO AN EXPERT

Want to learn more? Talk to a dust, mist and fume expert today by filling out the fields below.