DUST AND FUME COLLECTION CHALLENGES IN THE MILITARY AND DEFENSE INDUSTRY

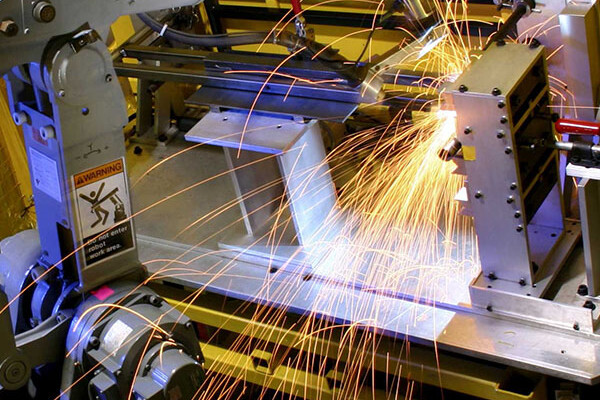

Manufacturers in this industry oversee many processes that produce air quality challenges. Welding stations and metal-cutting tables create fumes and dust that demand remediation, and the only way to do that is through vigorous collection and filtration of these substances. Failure to control air quality not only endangers workers’ health, it risks breaches in regulatory compliance.

Manufacturers in this industry oversee many processes that produce air quality challenges. Welding stations and metal-cutting tables create fumes and dust that demand remediation, and the only way to do that is through vigorous collection and filtration of these substances. Failure to control air quality not only endangers workers’ health, it risks breaches in regulatory compliance.

Dust and weld fumes are a serious problem when sensitive electronics are involved. The risk of contamination is real, and there is little room for error. The only answer is to actively filter the air and to maintain a high standard as vigilantly as possible.

Protecting workers’ health is accomplished with comprehensive dust and weld fume collection, as well. Metal-cutting operations and welding stations produce serious amounts of inhalable particulates. Many of these particulates contain toxic metals which can be absorbed into the body and can cause serious illnesses and diseases. For example, hexavalent chromium is produced by many welding processes. Exposure to this carcinogenic substance has been associated incidences of cancer.

The Occupational Safety and Health Administration (OSHA) has a specific regulation for hexavalent chromium, as well as for many other specific toxic metals. OSHA sets permissible exposure limits (PEL’s) to protect workers from excessive exposure to harmful airborne particulates.

The accumulation of dust can also create a fire hazard. The Bureau of Labor Statistics estimates that about 3% of workplace fatalities result from fires and explosions. This serious danger to workers and to property can be mitigated with effective filtration equipment and fire suppression devices.

Related Resources

SOLUTIONS FOR DUST AND FUMES IN THE MILITARY AND DEFENSE INDUSTRY

RoboVent’s comprehensive dust and weld fume collectors are well suited to the military and defense industry. They safeguard your products and prevent contamination. They protect your workers’ health and ensure compliance with air quality regulations. They also operate efficiently, saving on energy and maintenance demands.

RoboVent equipment also protects your operation from the risks of fire and explosion. Equipment features like the Delta 3 spark arrestor and the Supprex-200 fire suppression system protect your workers, property and production lines.

RoboVent’s advanced dust and weld fume collectors, such as the Fusion Series or the Spire Series, are good examples of systems that are powerful, flexible and budget-friendly. When a bigger system is needed, our Grid Configuration allows you to scale up your operation but still remain flexible.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.