Cutting Energy Costs: 10 Strategies for Smarter, More Efficient Dust Collection

Industrial dust collection and air filtration systems are essential for maintaining air quality, protecting worker health and ensuring compliance with environmental regulations. However, they can also be a significant source of energy consumption, driving up operational costs. The good news? Advances in system design, smart controls and maintenance strategies can drastically reduce energy use while improving performance and extending equipment life. Here are ten proven strategies to optimize your environmental systems for maximum energy savings.

Need help with air filtration system optimization? Connect with the experts at RoboVent!

1. Switch from Exhaust Ventilation to Air Filtration

If you’re still using traditional exhaust ventilation, the first step is to switch to an energy-efficient air filtration that returns heated or cooled air to the facility. Traditional exhaust systems expel conditioned air, forcing HVAC systems to work harder to maintain indoor temperatures, especially in facilities with extreme seasonal temperature variations. This constant loss of heated or cooled air drives up energy costs and places additional strain on climate control systems. By switching to filtration-based dust collection, clean, filtered air can be returned to the facility, significantly reducing heating and cooling demands while maintaining proper air circulation. This approach not only improves energy efficiency but also enhances worker comfort and environmental control, ensuring stable indoor temperatures and better air quality. Additionally, retaining conditioned air helps facilities comply with ventilation regulations while minimizing the need for costly makeup air systems.

Learn more: Industrial Air Filtration 101

When designing an industrial air quality system, choices must be made between filtration and exhaust and source capture vs. ambient capture. A source capture filtration system is the most energy efficient option for most applications.

2. Right-Size the Dust Collection System

Oversized or undersized dust collection systems are both costly mistakes. A system that’s too small won’t capture contaminants effectively, leading to poor air quality, regulatory compliance issues, and potential equipment damage. On the other hand, an oversized system wastes energy by moving more air than necessary, increasing operational costs and putting unnecessary strain on components. Proper system sizing accounts for airflow demands, static pressure losses, and the number of pick-up points to ensure efficient dust collection without overburdening the system. By designing a system tailored to your facility’s specific needs, you can minimize wasted energy, extend equipment lifespan, and maintain optimal filtration performance while ensuring a safe and compliant work environment.

Learn more: Dust Collector Sizing

3. Upgrade to Variable Frequency Drive (VFD) Motors

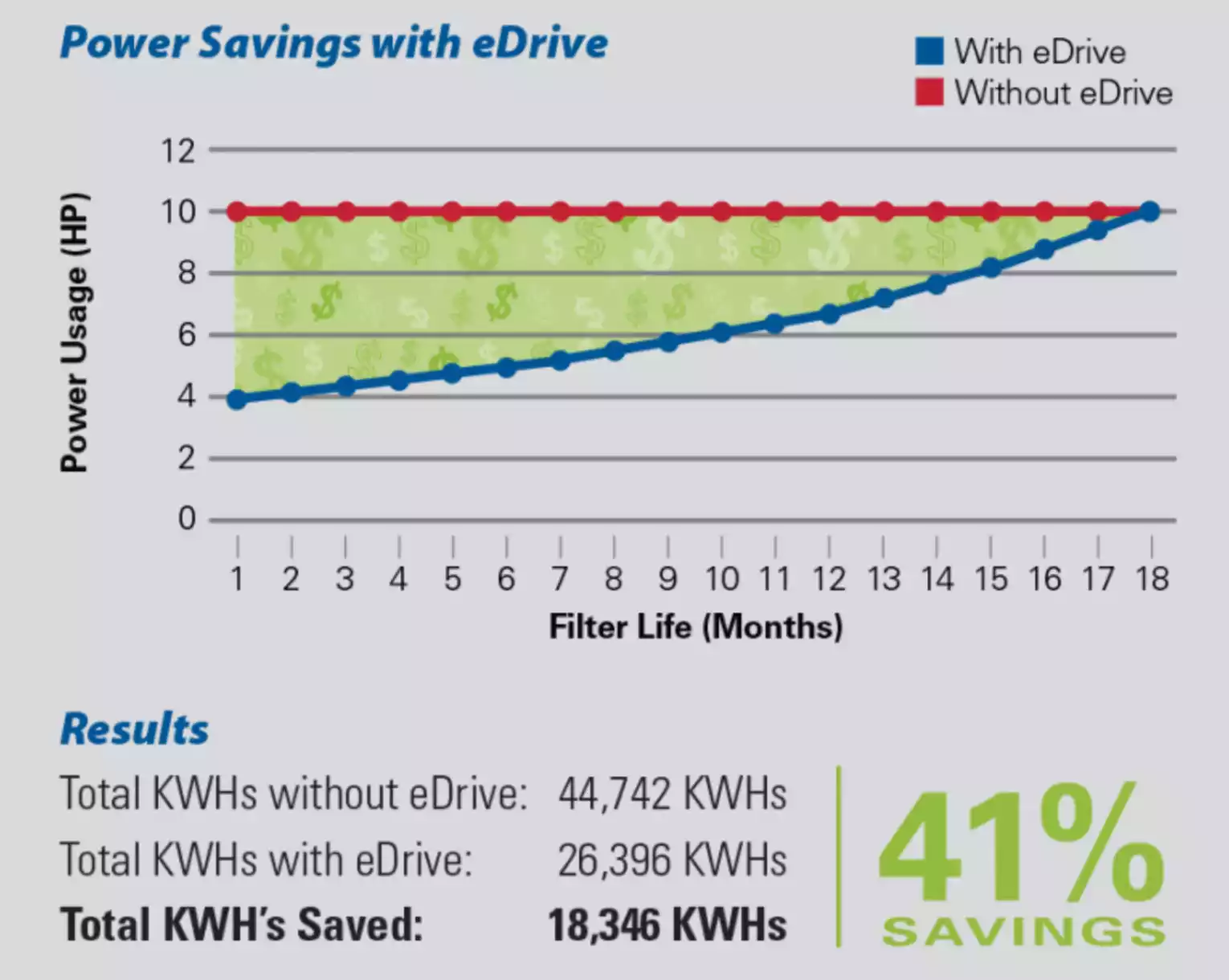

Traditional fixed-speed dust collector motors run at full power all the time, leading to unnecessary energy consumption and increased operational costs. A Variable Frequency Drive (VFD) motor can automatically ramp the motor speed up or down based on airflow requirements or resistance. For example, RoboVent’s eDrive VFD continuously monitors airflow and automatically adjusts the motor RPM to compensate for filter loading. This means the system uses less energy when filters are new and resistance is low. Motor speed ramps up gradually to overcome increasing pressure drop as the filters become loaded. This system decreases total energy consumption by 20-40% over the life of the filter while extending filter life by up to 30%. VFD motors can also be used in conjunction with intelligent control systems (see below) to ramp motor speed up or down in response to real-time airflow (CFM) demand.

Learn more: RoboVent eDrive

4. Use Zone-Based Extraction

Instead of running the entire dust collection system at full capacity, zone-based extraction directs airflow only to the areas where it is actively needed, reducing unnecessary energy use. This is achieved through automated dampers that open or close based on workstation activity, ensuring dust collection is only operating in zones where processes are generating dust. For example, in a large manufacturing plant with multiple workstations, certain areas may not be in use at all times. Zone-based extraction prevents air from being pulled from idle sections, reducing the total air volume (CFM) the system needs to move. This leads to lower fan power consumption, reduced wear on equipment, and improved overall efficiency. When integrated with VFD motors and demand-based control systems, zone-based extraction further enhances energy savings by preventing over-ventilation and optimizing airflow distribution across the facility.

5. Implement Smart, Demand-Based Control Systems

While zone-based extraction controls where air is pulled from, smart, demand-based control systems like the Nederman SAVE system manage how much air is moved and at what fan speed based on real-time conditions. Instead of running the dust collection system at a fixed rate, intelligent controls continuously monitor machine activity, filter loading and airflow needs and automatically adjust fan speed to match demand. This dynamic adjustment reduces energy consumption and minimizes unnecessary wear on motors and fans. The SAVE system takes this optimization further by integrating with facility monitoring software, allowing businesses to track performance, identify inefficiencies and further fine-tune energy savings.

6. Optimize Hood Design for Efficient Dust Capture

Implementing a source capture dust collection system saves energy by capturing contaminants as they are created, before they disperse into the general facility air. A well-designed source capture system minimizes the volume of air (CFM) that must be moved to capture dust effectively. The efficiency of a source capture system begins with proper hood design and positioning. Depending on the application, that might mean a full enclosure (like the Streamline Hood), a receiving hood, a backdraft plenum, or a close-capture hood such as a fume extraction arm or fume gun (for manual welding). Poorly placed or undersized hoods may require excessive airflow to compensate for inadequate capture efficiency, wasting energy in the process. Properly designed and placed hoods improve performance and minimize the amount of air that must be processed, ultimately leading to a more energy-efficient dust collection system.

An enclosing hood like this Streamline Hood is ideal for capturing fumes from robotic processes.

Fume arms are a form of close-capture hood used for weld fume extraction and similar applications involving fumed materials.

7. Improve Ductwork to Reduce Static Pressure

Poorly designed ductwork creates excessive static pressure, forcing fans to work harder and significantly increasing energy consumption. Every unnecessary bend, improperly sized duct or rough interior surface adds resistance, making it more difficult for air to move efficiently through the system. Optimizing duct layouts by using shorter, more direct runs, smooth interior surfaces, and gradual transitions helps minimize resistance and reduce the overall load on the system. Proper duct sizing is also critical; ducts that are too small increase velocity and pressure loss, while ducts that are too large reduce transport velocity, allowing dust to settle inside. A well-balanced ductwork system ensures even airflow distribution, prevents unnecessary energy use, and extends the lifespan of fans, motors, and filters. Regular inspections and adjustments can help identify airflow imbalances, leaks, or blockages that may compromise efficiency over time.

8. Choose the Right Filters

The right filter media can make a significant difference in both dust collection performance and energy efficiency. High-quality dust collector cartridge filters with a low initial pressure drop allow air to move more easily through the system, reducing the workload on fans and lowering overall energy consumption. Filters with advanced media technologies, such as nanofiber or PTFE coatings, offer superior dust capture efficiency while maintaining lower resistance, extending the time between cleanings or replacements. It’s also important to select the appropriate filtration efficiency for your application. Over-filtering—using filters with a higher efficiency rating than necessary—can create excessive resistance, increasing energy consumption and shortening filter life. For example, HEPA filters may be required for certain hazardous dusts but are unnecessary for general industrial applications where lower-efficiency filters can still meet air quality requirements while reducing system strain. Balancing filtration efficiency with airflow requirements ensures optimal dust capture without unnecessarily burdening the dust collection system, leading to both energy savings and longer filter life.

Learn more: Cartridge Filters Buyer’s Guide

9. Maintain Filters Properly

Regular filter maintenance is just as important as selecting the right filter. As filters accumulate dust, airflow resistance increases, forcing the system to work harder to maintain proper ventilation. If filters become overloaded or clogged, fan motors must compensate for this pressure drop by using more energy, driving up operational costs. A pulse-cleaning system uses compressed air to pulse excess dust off the filters during operation, reducing filter loading and extending filter life. Implementing a proactive maintenance schedule ensures that filters are replaced at the right intervals to prevent excessive pressure buildup and maintain system efficiency. Additionally, monitoring filter loading with smart controls or differential pressure sensors can help optimize pulse cleaning cycles, further improving energy savings and filter longevity.

Learn more: Extending the Life of Your Dust Collector Cartridge Filters

Proper filter maintenance will help save energy and reduce wear and tear on the dust collector.

10. Conduct Regular Inspections and Preventive Maintenance

Even the most energy-efficient dust collection system will lose efficiency if not properly maintained. Over time, dust buildup, clogged filters, worn fan belts, or leaking ductwork can force the system to work harder, increasing energy use. Regular inspections help identify leaks, blockages and worn components before they lead to costly failures or reduced performance. In addition to regular filter changes, a preventive maintenance plan should include checking ductwork for leaks, inspecting fan belts, ensuring dampers function properly, and monitoring filter loading. Using predictive maintenance tools, such as sensors and pressure monitoring, can further optimize system performance by detecting issues in real time and allowing proactive adjustments. This data-driven approach helps maintain efficiency, reduce downtime, and lower operational costs.

Learn more: Cartridge Dust Collector Maintenance Checklist

Need Help with Dust Collection Energy Optimization?

Implementing these energy-saving strategies not only reduces operating costs but also extends the life of your dust collection system, improves workplace air quality, and ensures compliance with environmental regulations. Many energy providers offer incentive programs that can help offset the cost of upgrades like VFD motors, smart control systems, and high-efficiency filtration. These programs are designed to encourage businesses to adopt energy-efficient technologies, and in many cases, they can significantly reduce or even cover the cost of implementation. Our team can help you identify available incentives and guide you through the process of maximizing your energy savings.

Optimizing dust collection for energy efficiency requires careful system design, advanced technology and expert knowledge. RoboVent’s system design and engineering team specializes in designing, upgrading, and maintaining industrial air filtration systems to maximize efficiency while ensuring compliance with workplace safety regulations. Whether you need a system assessment, equipment upgrade or advanced smart control solutions, RoboVent is ready to help you achieve your energy-saving goals.

Contact us today to start cutting costs without compromising air quality.

Contact Us With Your Questions!

SUBSCRIBE TO

BLOG UPDATES