Fire Suppression Options for Dust Collectors: Making the Right Choice

Dust collectors are responsible for nearly 15% of industrial fires and explosions in North America, according to dustsafetyscience.com. That’s why every dust collection system should be equipped with some form of fire suppression or fire extinguishing system. There are several options to choose from, including water sprinklers, carbon dioxide (CO2) gas, and clean agent gas systems. Here’s what you should know about dust collector fire suppression.

Does a dust collector need fire suppression?

Yes, all dust collectors should have some form of fire suppression technology. At a minimum, there should be a fire extinguisher mounted near the collector in case a fire breaks out in the filter cabinet. However, in most circumstances, a cartridge dust collector should have an internal fire suppression system that is automatically triggered by smoke or heat. A dust collector fire suppression system may use water, a gas (such as CO2) or a chemical to put out the fire or suppress it until firefighters arrive.

A cartridge dust collector provides an ideal environment to sustain a fire—all it takes is a single spark to get it started. The dry filter media provides fuel for a fire. A dust collection system also provides lots of airflow, bringing fresh oxygen in to sustain and grow a fire. The risk is amplified when collecting combustible dust. Combustible dusts include most metal dusts, virtually all food dusts, woodworking dust (i.e., sawdust), and plastic dust. The three elements needed to start and sustain a fire—heat, oxygen and fuel—are known collectively as the Fire Triangle.

What is the difference between fire suppression and fire extinguishing?

Fires can be stopped in several ways, including cooling (typically with water), smothering (preventing oxygen from reaching the fire), starving (removing the fuel source), and interrupting the combustion process (using a chemical). These approaches may either extinguish or suppress the fire.

- A fire extinguisher puts out the fire. A water sprinkler system will extinguish a fire by cooling.

- A fire suppression system is not designed to totally extinguish a fire, but to keep it from growing or spreading until firefighters arrive. Fire suppression generally uses a gas or chemical to smother the fire or a chemical that interrupts the combustion process.

Both approaches can be safe and effective, but they may not be equally appropriate for every dust type and dust collector configuration. Ultimately, the dust collector fire protection system must be selected based on the application.

What type of fire protection is recommended for dust collectors?

There are several options for dust collector fire protection. The right choice depends on variables such as the type of dust collected, the presence of other risks such as flammable or explosive gases, and the type and location of the dust collector. Common systems include:

- Water sprinkler fire extinguisher systems

- Carbon dioxide fire suppression systems

Until recently, companies also had the option of a clean agent gas system such as FM-200 gas. However, these systems are being phased out under the American Innovation and Manufacturing (AIM) Act due to the use of hydrofluorocarbons (HFCs). In situations where a water sprinkler system is not appropriate (such as the presence of combustible metal dust), a CO2 gas system should be used. Firefighting foams are not typically used in dust collectors.

What class of fire is a dust collector fire?

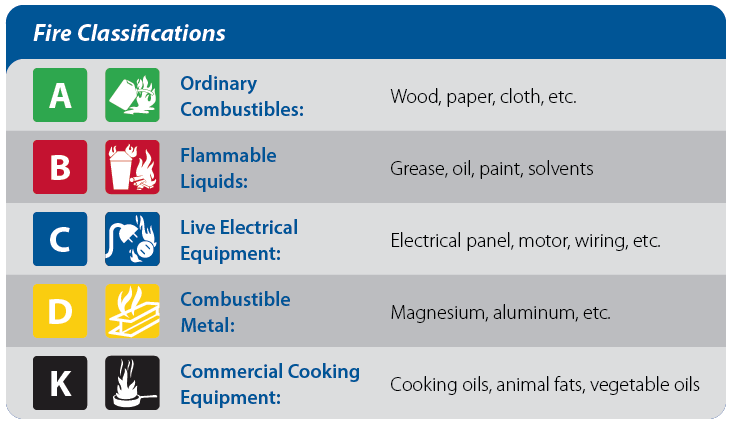

The most important consideration in choosing a fire protection system for a dust collector is the type of material collected and the class of the resulting fire. Fires are classified by the National Fire Academy into five types: A (Ordinary Combustibles), B (Flammable Liquids), C (Live Electrical Equipment), D (Combustible Metal), and K (Cooking Fats and Greases).

- The majority of dust collector fires are Class A fires. The filter material and many common dust types (food dust, paper or wood dust, textile dust, plastic dust, etc.) would fall under Class A if a fire broke out in the dust collector. Class A fires can be safely extinguished or suppressed with water, with CO2 gas or with chemical agents.

- Class B fires can occur in the dust collection system if a flammable gas or liquid is present along with the dry dust. For Class B fires, a dry chemical system is recommended to smother the fire.

- Class C electrical fires can occur in a dust collection system, as with any other type of electric-powered equipment. For a Class C fire, immediately shut down electricity to the unit and use a non-conductive chemical fire suppression agent.

- When collecting combustible metal dust—such as magnesium, titanium, potassium or aluminum—a Class D fire may result. Class D fires can NOT be put out with water; water and other liquids may instead make the fire worse. A dry powder chemical agent is usually recommended for Class D fires. Inert gases such as argon or Inergen may also be used.

Fire Protection Options for Dust Collectors

Each of the fire protection options for dust collectors has its pros, cons and recommended applications.

Water Sprinkler Systems

A dust collector sprinkler system is hooked up to the general water supply for the facility. Sprinkler head ports are mounted inside the filter cabinet. If a fire is detected inside the dust collector, the sprinkler system turns on, dousing the filters with water.

- How it works: A sprinkler system extinguishes the fire by cooling; as water hits the filter material and accumulated dust, it lowers the temperature below the temperature required to sustain a reaction.

- Pros: A sprinkler system is a simple and cost-effective solution for most common dust collector fires. Water extinguishes the fire vs. merely suppressing it.

- Cons: Water extinguishing is messy and may cause damage to the dust collector and its surroundings. If the dust collector is located indoors, the sprinkler system may flood the area and damage nearby equipment or cause water damage to the facility.

- What it can be used for: Water sprinkler systems can be used only for Class A fires.

Carbon Dioxide (CO2) Fire Suppression System

A high-pressure carbon dioxide fire suppression system releases CO2 into the dust collector filter chamber. A canister of pressurized CO2 gas is mounted to the dust collector. Release may be triggered by a sensor system or a passive release system. CO2 gas is colorless, odorless and electrically non-conductive. It can suppress a wide variety of fire types. It is considered a fire-suppressing, rather than extinguishing, technology.

- How it works: CO2 gas smothers the fire by displacing the oxygen in the enclosure, reducing oxygen levels below those required to sustain a combustion reaction. It also has a cooling effect as it leaves the pressurized chamber and returns to atmospheric pressure.

- Pros: Unlike water, CO2 gas will not cause damage to the equipment or facility, does not leave any residue, and does not require expensive clean-up. It is also safe for electronics. It is highly effective in suppressing many types of fires.

- Cons: CO2 gas is not safe for humans or animals to breathe. It is best for use in outdoor dust collectors or in areas where humans are not present. If the dust collector is inside, an alarm system should be added to alert humans that they need to leave the area immediately.

- What it can be used for: CO2 gas can be used for class A, B and C fires.

What are the elements of a dust collector fire protection system?

For total fire safety, the dust collector should be equipped with several elements, including:

- A fire suppression system or fire extinguishing system that automatically deploys if a fire is detected.

- A smoke/fire detector (a thermal/ionization dual sensor system is recommended) that will shut down the dust collector in case of a fire.

- An automated damper system to shut down airflow to the collector.

- A spark arrestance system (if sparks are produced near the dust collector intake or ductwork).

- If dust is combustible, an NFPA-compliant deflagration system will also be required, consisting of explosion venting (standard or flameless) and mechanical isolation (isolation valves, rotary airlocks).

Read more:

What regulations apply to dust collector fire and explosion safety?

In the U.S., dust collection systems are regulated by the Occupational Health and Safety Association (OSHA) and must meet standards set by the National Fire Prevention Association (NFPA) for fire and explosion safety. In Canada, fire safety standards are set by the province or territory but typically mirror NFPA requirements. The NFPA standards, along with the International Fire Code (IFC), provide a basis for regulation worldwide.

NFPA sets standards that apply to many aspects of dust collection system design and maintenance, including airflow velocities/capture rates, spark/ignition control, deflagration system components (for combustible dust), fire suppression, material handling and maintenance. Standards that apply to collection of flammable or combustible dust include:

- NFPA 68: Standard on Explosion Prevention by Deflagration Venting

- NFPA 69: Standard of Explosion Prevention Systems

- NFPA 652: Standard on the Fundamentals of Combustible Dust

- NFPA 654: Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing and Handling of Combustible Particulate Solids

Industry-specific NFPA standards include:

- NFPA 484: Combustible Metals

- NFPA 61: Agriculture and Food Processing

- NFPA 664: Wood Processing and Woodworking Facilities

(Note: many of the combustible dust standards will be consolidated under the NFPA Combustible Dust Consolidation Plan under the new NFPA 660, currently under development.)

Manufacturers should work with an engineering partner who is familiar with their regulatory environment and the applicable NFPA standards for their industry.

Which dust collector fire protection system is right for you?

There is no “one-size-fits-all” answer when it comes to fire protection for dust collectors. There are several factors to consider, including:

- The type, volume and physical characteristics of the dust.

- The type of dust collector (cartridge, baghouse, cyclone, electrostatic, wet collection, etc.) and filter media.

- The location of the collector.

- The presence of an explosive atmosphere or flammable oils and liquids.

- The presence of potential ignition sources, including sparks, heat or open flames.

The choice of fire suppression/extinguishing system should be made within the context of a holistic risk evaluation and fire prevention plan for the dust collection system.

If you’re not sure which fire suppression system is right for you, the fire safety experts at RoboVent can help. Contact us for a fire safety evaluation of your dust collection system.

Contact Us With Your Questions!

SUBSCRIBE TO

BLOG UPDATES