Dust Collector Fire Prevention Awareness

Six Fire Safety Tips to Prevent Dust Collector Fires

Fire safety is a top priority in manufacturing! Dust collector fires are rare, but they do happen—and they have the potential to do a lot of damage to your facility. Fortunately, dust collector fires are almost entirely preventable with some proactive maintenance and safety precautions.

Here are six things you should do to reduce the risk of a dust collector fire. Download our dust collector fire safety checklist for complete instructions.

- Clean and inspect your dust collector smoke detector. Your smoke detector is your first line of defense! Make sure it is clean and working properly.

- Contain uncontrolled sparks near your dust collector. If you have uncontrolled sparks from welding, cutting or grinding, consider adding a curtain or containment system.

- Check your dust collector fire suppression system. If a fire breaks out inside your dust collector, your fire suppression system will kick in to put it out. Inspect your system regularly.

- Clean up the area around your dust collector. Housekeeping matters! Remove flammable or combustible products near dust collectors and spark-producing processes.

- Check and clean your spark arrestors. Your spark arrestor should be cleaned regularly to prevent the buildup of combustible debris and ensure proper airflow.

- Check filter pressure. High filter pressure indicates that airflow is obstructed, which will reduce the effectiveness of your spark arrestor. Check filter pressure daily!

Picking the Right Dust Collector Smoke Detector

Fire safety starts with effective fire detection. In addition to your general building smoke detection system, you need to have a smoke detector for your dust collector. There are several kinds of smoke detectors to choose from. For dust collectors, an Ionization/Thermal Dual Sensor is typically recommended.

| Ionization | Photoelectric | Thermal | Ionization/ Photoelectric Dual Sensor | Ionization/ Thermal Dual Sensor |

|---|---|---|---|---|

| Generally more responsive to flaming fires | Generally more responsive to smoldering fires | Great for use in areas with excessive amounts of dust and debris | Best detector for places where the fire type is not constant | Best detector for places where dust is present |

| Common smoke detector, cheap | Common smoke detector, cheap | Usually used with an ionization detector | Slightly more expensive than the single-sensor detectors | Double the price of the ionization/ photoelectric dual sensor |

Stop the Sparks

Many dust collector fires are started by sparks that travel through the ductwork and into the dust collector. Filter media and combustible dust inside the dust collector provide the perfect fuel for a dust collector fire. You can prevent most collector fires by reducing the risk that a spark will find its way into the system.

There are two main ways to control sparks. If your processes produce a lot of sparks—as is typical with welding, cutting and grinding—you may need both types of spark mitigation.

- Spark containment: Your first line of defense is to contain as many sparks as possible near their source. This can be accomplished by installing a curtain or screen between the spark-creating process and the dust collector intake. RoboVent can help you install a spark containment system.

- Spark arrestance: To be sure that sparks do not make it to the filters, you may also need to install a spark arrestor on your dust collector. The spark arrestor can be installed at the intake, inline in the ductwork or attached to the collector. There are several kinds of spark arrestors you can choose from.

| Spark Suppression Method | Maintenance | Pros | Cons | Comments |

|---|---|---|---|---|

| RoboVent Delta3 Inline | When high air velocities are maintained, minimal maintenance required to remove collected debris from trap | • Industry-leading spark control and safety • Lower pressure drop for energy savings • Easy inline installation • High-quality welded construction | • Cannot guarantee 100% spark reduction (though tests show it comes very close) | Uses centrifugal force to strip the thermal envelope from sparks. Highly effective at spark control for applications producing a large number of sparks (e.g., metalworking) A minimum air velocity is required for adequate spark reduction |

| Metal Mesh | Requires regular maintenance to clean debris | • Cheapest option • Easy Installation • Increases filter life | • Requires frequent maintenance to clean loaded screens • High pressure drop when screens are loaded • Loaded screens can create a fire hazard • Less effective at spark reduction than centrifugal arrestors | Uses one or more mesh screens to block the passage of sparks. Often used for weld fumes and on internal combustion engines and chimneys |

| Detect-and-Suppress System | Extra maintenance to take out the filters for drying | • Known to fully extinguish sparks • IR detection that can also be connected to fire suppression system | • Filters can get wet and decrease performance • Substantially more expensive than alternatives | Uses a sensor to detect sparks and activate a water or chemical extinguishing system Generally used for high-risk environments (e.g., explosive atmospheres) |

Read more about spark control options.

The RoboVent Delta3™ Inline spark arrestor uses centrifugal force to kill sparks before they have a chance to ignite. In head-to-head comparative testing against industry leaders, Delta3 Inline extinguished the competition with the best combination of spark control and efficiency. Delta 3 Inline:

- Allowed zero sparks through at all tested airspeeds.

- Tied for lowest pressure drop among all tested technologies.

Put it Out: Dust Collector Fire Suppression Systems

Your dust collector should have an internal fire suppression system. These systems will put out a dust collector fire as soon as it is detected, preventing wider damage to the facility. They typically have three parts:

- A sensor to detect the fire (smoke or heat).

- An automatic damper to shut off incoming oxygen and smother the fire.

- A fire-suppression agent that is released inside the collector to stop the fire in its tracks.

There are three main types of fire suppression systems.

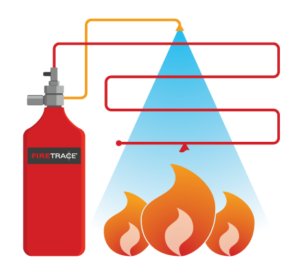

Direct release system

A local application system that uses the Firetrace detection tubing to both sense the fire and deliver the agent to the protected space. When exposed to fire the tubing bursts, forming a nozzle that directs the suppression agent.

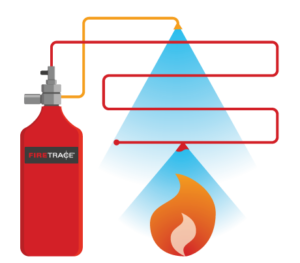

Indirect release system

A total flooding system that uses the Firetrace detection tubing only as a sensing device. Upon detection, agent is delivered into the protected space using pipes or hoses and fixed nozzles.

Dual action system

Combines the functionality of the direct local application system and indirect total flooding system. By delivering agent through both nozzles and the tubing burst, a more complete and effective suppression is achieved.

Fire suppression agents may be dry chemical, gas, foam or liquid. Here are the pros and cons of different fire suppression agents.

Learn more about the RoboVent Supprex-200 Fire Suppression System.

Reducing Fire and Explosion Risks from Combustible Dusts

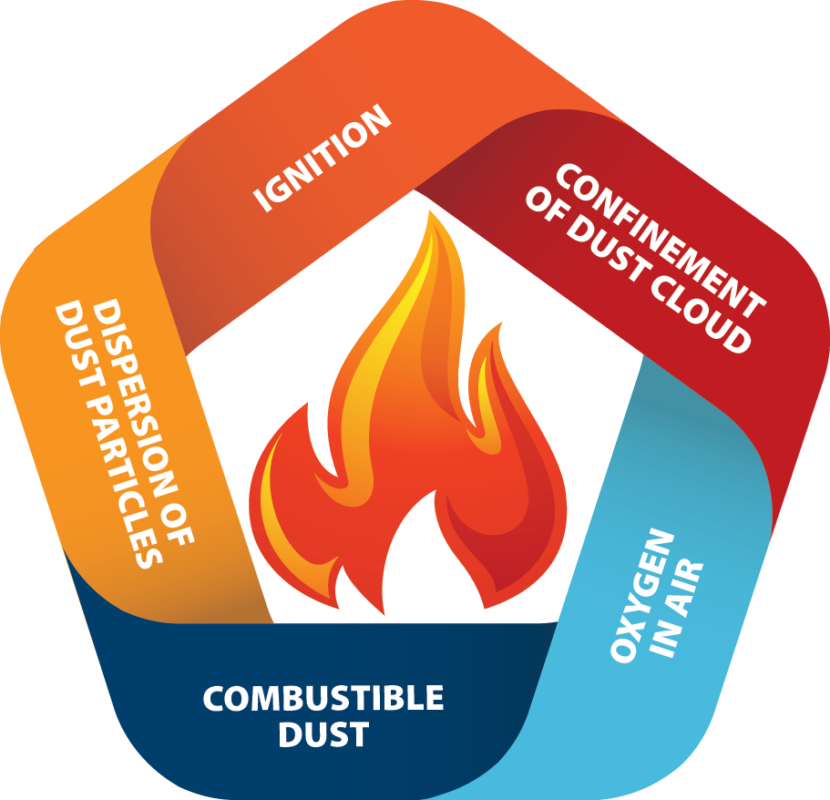

Many of the dust types created in manufacturing processes—including metalworking dusts, paper and cardboard dust, food and grain dust, wood dust and many synthetic dusts—are combustible. That means they can cause an explosion under the right conditions. While combustible dust explosions are rare, when they happen, they can be catastrophic.

There are five elements necessary for a combustible dust explosion:

You can prevent dust explosions by removing one or more of the five elements. Learn more about combustible dusts.

Need Help with Fire Safety?

RoboVent is your partner for fire safety and dust collector fire prevention. We can:

- Perform annual safety inspections of dust collectors and related equipment and perform regular preventative maintenance to ensure that your equipment is safe and in tip-top condition.

- Conduct a Dust Hazard Analysis (DHA) to assess your risk of fire, flash fire or combustible dust explosion.

- Install a spark containment system and spark arrestor to prevent sparks from igniting your dust collector.

- Help you develop a fire prevention strategy and select and install appropriate smoke detectors and fire suppression systems for your dust collector.

Contact us today to schedule your equipment safety inspection or discuss your fire safety concerns.