Dust and Fume Control Solutions for Construction Equipment Manufacturing

Heavy equipment manufacturing often involves multiple production areas, mobile workstations, and open layouts that must accommodate cranes, forklifts and large materials. RoboVent specializes in designing industrial dust collection systems for complex facilities like these, where flexibility, durability and performance are non-negotiable.

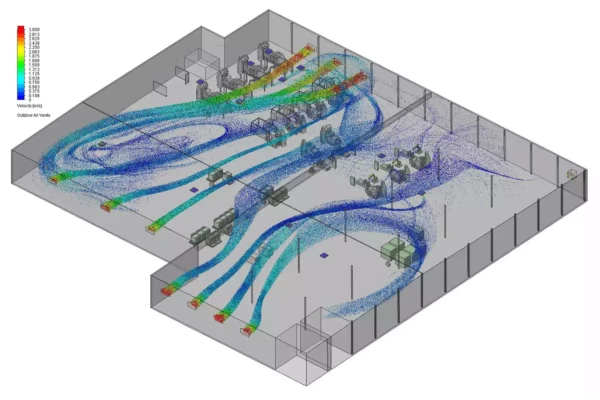

From welding fumes to thermal cutting dust and oil mist, our engineered systems are tailored to your specific processes and plant layout. Whether you need a tough high-capacity dust collector like Senturion®, a flexible ambient air filtration solution like RoboVent Vortex®, or oil mist collection with Clarion®, RoboVent has a system built to handle it. For ambient air filtration system design, our VentMapping® computer-aided engineering process ensures every system is optimized for airflow, process demands and compliance requirements.

Related Resources

Processes in Construction Equipment Manufacturing

Airborne contamination in construction equipment manufacturing is generated by a diverse set of fabrication and assembly operations. These often take place on large, heavy-gauge parts that are difficult to contain and require frequent repositioning or manual work. Key dust- and fume-generating processes include:

- Welding: Both manual and robotic welding (MIG, TIG, FCAW) are widely used to assemble frames, arms and structural joints. These processes generate metal fumes, especially when working with coated or alloyed steels.

- Thermal lancing: May be used for rework, disassembly or maintenance of high-strength construction equipment components. Produces high heat, slag, sparks and metal fumes.

- Hand plasma cutting: Used to trim, modify or cut through structural elements and attachments. Cutting coated or galvanized materials generates ultrafine metal particulate and toxic gases.

- Grinding and finishing: Surface prep and post-weld cleanup operations produce dry, respirable metal dust, which can accumulate quickly in open workspaces.

- Machining and drilling: Precision work on brackets, frames, and hydraulics may release metal shavings or oil mist when coolant is used.

- Abrasive blasting: Applied to clean or roughen surfaces before painting or welding. Dry blasting of painted parts creates dust that may contain lead, chromium or VOCs from coating residues.

Heavy equipment manufacturing for the construction industry involves processes like welding, hand plasma cutting, grinding, and abrasive blasting--all of which generate toxic or hazardous dust and fumes.

Air Quality Challenges in Construction Equipment Manufacturing

Unlike small parts manufacturing, the scale and mobility of construction equipment fabrication introduce unique ventilation challenges. Some of the most common issues include:

- Wide dispersion of fumes and dust: Workers move freely around oversized workpieces, making it difficult to position traditional source capture systems. Without ambient filtration, particulates can spread throughout the facility.

- Exposure to hazardous materials: Welding and cutting coated or alloyed materials may release substances like hexavalent chromium, nickel, manganese and VOCs, all of which are regulated due to health risks.

- Combustible dust risk: Processes such as grinding, blasting and thermal cutting generate dust that may become explosive when suspended in air—especially when cutting aluminum or working with dry powders.

- Oil mist and fluid aerosol exposure: Machining and drilling can produce airborne metalworking fluid mists, which may cause irritation, respiratory illness or skin issues if not properly captured.

Health and Safety Considerations

Construction equipment manufacturing plants—like other heavy fabrication environments—expose workers to a range of physical, thermal and respiratory hazards. Welding arcs, grinding sparks and heat sources create visual, auditory and burn risks. But the greatest long-term health threats come from inhalation of toxic metal fumes and fine particulate.

These airborne contaminants are produced during common operations like welding, thermal cutting, grinding, machining and blasting. Fumed metallic particles from thermal processes are ultrafine and respirable, making them especially dangerous when inhaled repeatedly over time. Others are coarse but highly irritating to lung tissue, such as dust from abrasive blasting or grinding. Toxic substances commonly encountered in construction equipment manufacturing include hexavalent chromium, manganese, nickel, cadmium, and oil mist from metalworking fluids. These are associated with serious health risks, including:

- Metal fume fever, which causes flu-like symptoms from acute exposure to metal oxide fumes.

- Lung cancer, linked to long-term exposure to hexavalent chromium and nickel.

- Chronic respiratory illness including bronchitis, asthma, and diminished lung function.

- Neurological effects such as manganism from manganese exposure, which causes Parkinson’s-like symptoms.

- Skin and eye irritation due to direct contact with fumes, dust, or oil mist.

- Respiratory sensitization, leading to allergic reactions or occupational asthma.

Lipoid pneumonia and dermatitis related to chronic oil mist exposure or skin contact with metalworking fluids.

Regulatory Compliance for Construction Equipment Manufacturing

To meet regulatory standards and ensure safe operation, construction equipment manufacturers must address OSHA dust regulations and other standards regarding worker safety, fire prevention, and environmental emissions control.

- Worker Exposure Limits: Employers must adhere to Occupational Safety and Health Administration (OSHA) permissible exposure limits (PELs) for airborne contaminants and maintain exposure below hazardous thresholds through ventilation and filtration. NIOSH and ACGIH recommend more stringent exposure limits that can serve as internal targets for risk reduction.

- Combustible Dust Compliance: The newly unified NFPA 660 from the National Fire Protection Association standard governs combustible dust safety, including requirements for dust hazard analysis (DHA), spark arrestors, explosion venting and system isolation. Stainless steel, aluminum and magnesium dusts are of particular concern in this industry. Dust collection systems must adhere to explosion protection requirements outlined in NFPA 68 (Explosion Protection by Deflagration Venting) and NFPA 69 (Explosion Prevention Systems).

Environmental Regulations: Cutting, welding, or grinding coated parts may release hazardous air pollutants (HAPs) or VOCs subject to the U.S. Environmental Protection Agency (EPA) Clean Air Act. A well-designed dust and fume control system with proper filtration ensures ongoing environmental compliance.

Industrial Dust Collection System Design in Construction Equipment

Construction equipment manufacturing facilities must be outfitted with industrial dust collection systems that are scalable, durable and adaptive to variable workflows, and compliant with OSHA dust regulations. Key considerations include:

- Source capture: For fixed stations and localized tasks like grinding or bench welding, high-vacuum source capture systems can remove fumes directly at the arc. Welders working on large assemblies may benefit from fume guns paired with portable collectors like the ProCube® II.

- Ambient filtration: In large, open production bays with overhead cranes or mobile welders, ambient air filtration may be the most practical solution. Vortex® ductless systems can be deployed strategically to draw contaminated air away from workers and return clean air to the workspace.

- Spark and explosion protection: System should include spark arrestors, fire suppression and explosion vents where thermal operations or combustible materials are involved. RoboVent’s Delta3® Inline Spark Arrestor integrates easily into these designs.

- Filter efficiency and safety: High-efficiency, flame-retardant dust collector cartridge filters engineered can help to manage high particulate loads and fine particulate. HEPA or gas-phase activated carbon after-filters may be required for capturing hazardous or recirculated fumes.

- Airflow and zoning: Facilities should be engineered for proper air movement, with directional flow that protects workers and equipment. Retractable enclosures, such as the DuroRoom, create containment zones around large equipment during welding, grinding, or finishing, while retracting to allow access for cranes.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.