DUST AND FUME COLLECTION CHALLENGES IN GENERAL FABRICATION

Air quality concerns in general fabrication originate in common processes such as cutting, machining and welding. As any floor manager knows, dust and fumes can create serious challenges for worker health, plant cleanliness and regulatory compliance.

Air quality concerns in general fabrication originate in common processes such as cutting, machining and welding. As any floor manager knows, dust and fumes can create serious challenges for worker health, plant cleanliness and regulatory compliance.

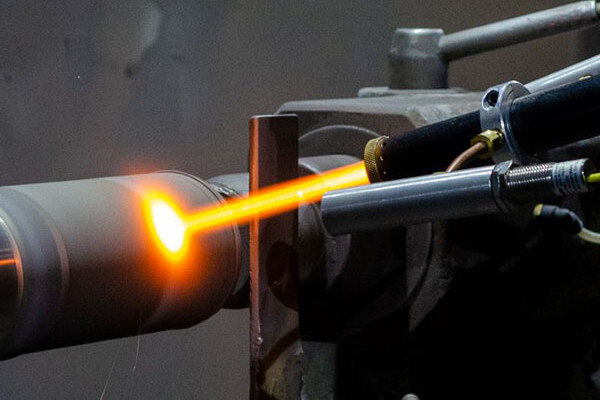

Welding, in particular, presents serious health concerns, since many weld fumes contain toxic metals. The extreme heat involved in welding creates fumes with metal particulates less than a micrometer in diameter. When toxic particulates are inhaled, their small size allows them to travel deep into the lungs and be absorbed into the body. Hexavalent chromium is a good example of a commonly produced and dangerous weld fume particulate. This substance is a known carcinogen. Without a fume collection system in place, workers are at risk throughout an entire facility.

Besides the pressing concern of worker health, worker recruitment and retention should be on manufacturers’ minds, as well. The American Welding Society estimates that manufacturing will see a shortfall of 290,000 skilled welders by 2020. Recruiting and retaining the best workers will become more and more challenging in the near future. A healthy, clean and attractive workplace free from haze and hazards is crucial.

Fires and explosions are other serious concerns for general fabrication operations. The Bureau of Labor Statistics estimates that these events cause about 3% of workplace fatalities. Cutting tables and other such equipment produce dust which can be combustible. A dust collection system can prevent a buildup of dust, and a spark arrestance system can further safeguard a facility from dangerous fires and explosions.

Complying with federal regulations on air quality is another mandate for a general fabrication operation. The Occupational Safety and Health Administration (OSHA) sets these standards to ensure workers have clean air and a safe workplace. For example, welding facilities must comply with air contaminant requirements that address permissible exposure limits (PELs) for specific toxic substances, such as inhalable manganese and hexavalent chromium. Failure to comply with these regulations can lead to serious fines.

Related Resources

SOLUTIONS FOR DUST AND FUMES IN GENERAL FABRICATION

RoboVent has its origins in the automotive parts industry and understands the processes and challenges of general fabrication. RoboVent provides affordable equipment and engineering services to make your facility safer, healthier and more efficient.

Lower operating costs with RoboVent equipment are achieved through automated systems. Dust collectors only run when they need to, seriously reducing energy use. No operation can afford downtime caused by a failed or finicky dust collector, so reliability and easy maintenance have been designed into RoboVent equipment.

The Spire dust collector is an example of a device well suited for general fabrication. This efficient, space-saving equipment can also be outfitted with a Delta 3 spark arrestor and a Supprex-200 Fire Suppression System to reduce the risk of fires in ductwork. If a facility needs a larger system, the RoboVent Grid ducted collector can easily be scaled up. For applications where a source capture system is not an option, RoboVent also offers ambient collectors like the Vortex Series collector.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.