DUST AND FUME COLLECTION CHALLENGES IN THE SHIPBUILDING INDUSTRY

Any workplace that involves welding or metal-cutting operations faces numerous air quality challenges. As shipbuilders know, the Occupational Safety and Health Administration (OSHA) issues standards for air quality in the industry. Title 29 Code of Federal Regulations (CFR) Part 1915 holds numerous regulations that manufacturers need to be mindful of. Failure to comply can carry serious legal and financial liabilities. Few industries receive this level of scrutiny. As OSHA says, these standards apply to workers “on the shore, pier, terminal, yard, shipyard, machine shop, riverbank, etc., as well as on the vessels afloat or in drydocks or graving docks.”

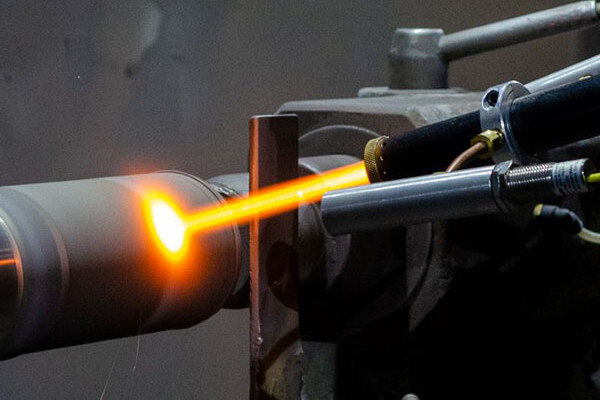

Workers’ health is a serious concern, as well. Weld fumes, in particular, are a major inhalation hazard. The high levels of heat involved in welding produce particulates of microscopic size; these particulates are easily inhaled and quickly become dangerous for workers. Substances such as hexavalent chromium travel in weld fumes. This byproduct of welding stainless steel is a known carcinogen and, when inhaled, has been linked to incidences of cancer. OSHA regulates workers’ exposure to other weld fume components, as well, including manganese and beryllium. Exposure to these substances carries serious risks, from major respiratory problems to manganism, a condition with symptoms similar to Parkinson’s Disease.

Shipbuilding creates serious air quality challenges in part because of the nature of the weldments seen in the industry. Welders move along large components, making it difficult to capture the weld fumes produced. Constantly moving a fume arm is often impractical, or at the very least inconvenient. Welders, under pressure to meet deadlines, often fail to keep up with fume capture. Another challenging situation is welding in a ship’s hold. This frequently encountered situation makes it very difficult for the welder to capture weld fumes, at least with conventional equipment.

The shipbuilding industry, and many others, faces yet another challenge, today: attracting and retaining skilled workers. Young workers are turning to service sector jobs, rather than manufacturing, and a skills gap has appeared. The American Welding Society estimates that manufacturers will see a shortage of 290,000 skilled workers by 2020. One way for employers to set themselves apart and attract the best workers is to maintain a clean and safe workplace. Good air quality is a key component of that.

Related Resources

SOLUTIONS FOR DUST AND FUMES IN THE SHIPBUILDING INDUSTRY

For decades, RoboVent has designed, manufactured and installed the best air filtration equipment in the industry. RoboVent understands the needs of the shipbuilding industry and has a solution for every application. One of our most advanced and applicable products is the MIG fume gun. This revolutionary fume gun provides unrivaled flexibility and source capture of weld fumes. Much lighter in weight than previous generations of fume guns, the Extractor delivers the highest quality welds while collecting weld fumes efficiently. Welders working in the tightest of spaces or moving along the largest of weldments are protected by the Extractor’s powerful fume evacuation. Plus, employers can be assured that regulations are met, as workers’ exposures are kept to a minimum.

Facilities with a need for a larger collector or a building-wide system are suitable for the Fusion Series Series of collectors. This system is designed to save energy while delivering powerful air filtration. Larger operations can opt for the Grid Configuration. This scaled-up array provides powerful fume and dust collection with a high degree of efficiency. For smaller and lighter applications, RoboVent makes a number of portable collectors. These offer a range of fume arms or hoods to protect workers and everyone else in a facility.

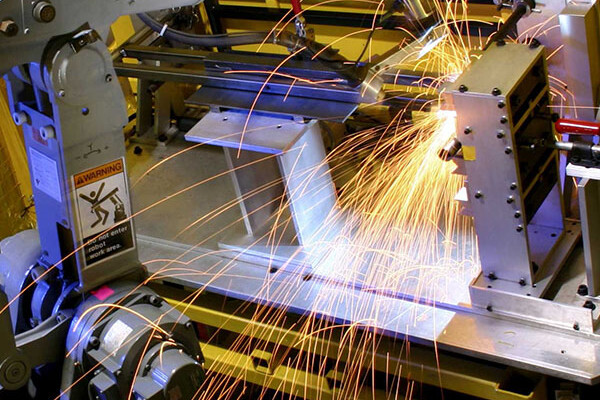

Fire and explosion threats are minimized with RoboVent’s proprietary solutions, as well. The Delta 3 spark arrestor and the Supprex-200 Fire Suppression System stop fires before they start. These systems protect workers, property and production lines.

As always, RoboVent guarantees satisfaction. Our manufacturing standards are the highest in the industry, and our warranty is the best in the business.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.