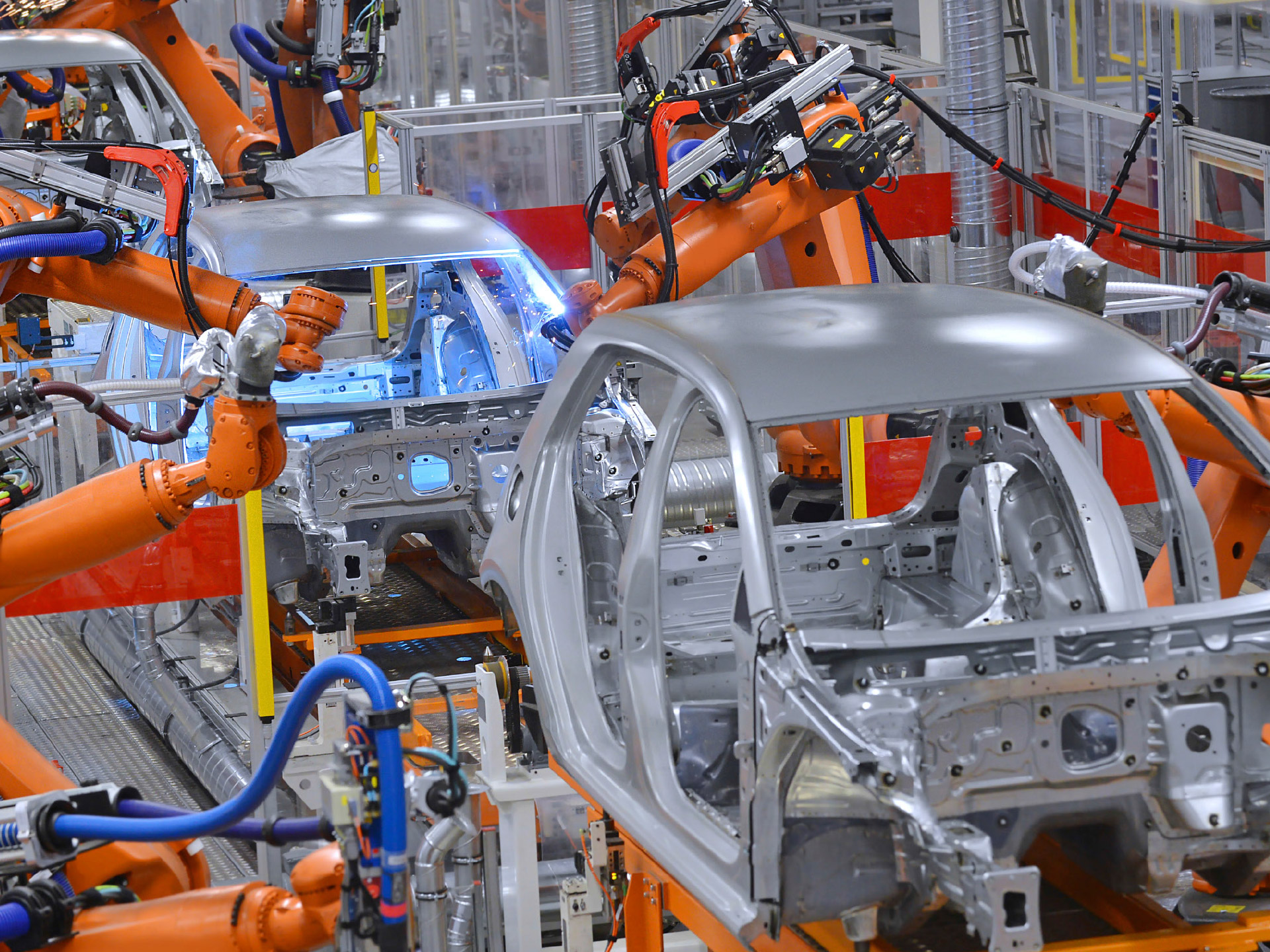

DUST AND FUME COLLECTION CHALLENGES IN THE AUTOMOTIVE INDUSTRY

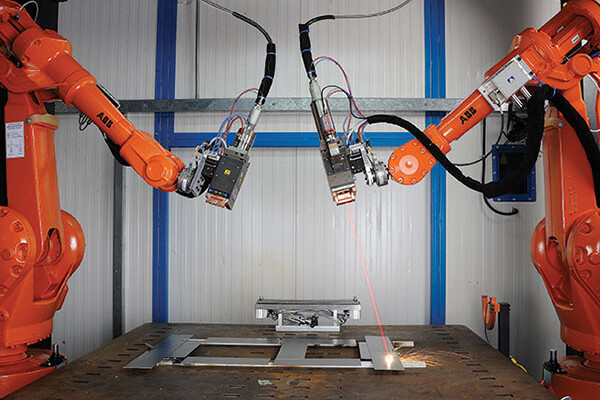

Automotive manufacturing entails many processes that produce serious air quality concerns. Whether the source is a cutting table or a robotic welding cell, dust and fumes are a problem for worker health, plant cleanliness and regulatory compliance.

Many dusts and fumes in the automotive industry contain toxic metals that constitute a serious danger to workers. The extreme heat involved in welding creates fumes with metal particulates less than a micrometer in diameter. The smaller the particulate the easier it is inhaled and absorbed into the body. Toxic particulates such as hexavalent chromium can travel in these fumes. Exposure to this substance is known to cause cancer and other serious health problems. Without a comprehensive dust and weld fume control system in place, workers are at risk throughout an entire facility.

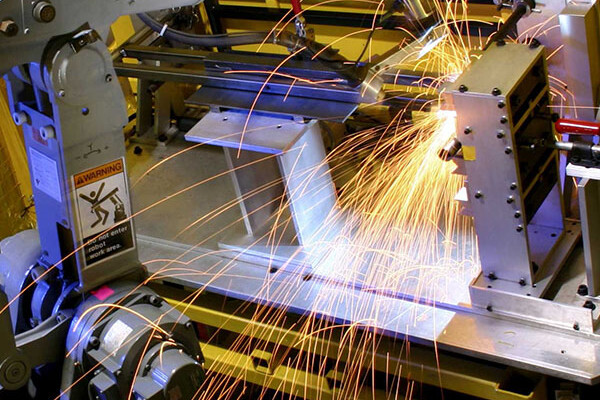

Dust in automotive manufacturing can produce a fire hazard, as well. According to the Bureau of Labor Statistics, fires and explosions account for about 3% of workplace fatalities. Because sparks, flames and combustible dust are an inherent part of the metalworking process, manufacturers must address this danger. A high quality dust collection system can stop fires before they start with a spark arrestance system.

Besides ensuring worker health, manufacturers must think about worker retention. A report by the Manufacturing Institute and Deloitte estimates that 2.1 million U.S. manufacturing jobs could go unfilled by 2030 due to the manufacturing “skills gap.” With fewer young people pursuing manufacturing careers, and many experienced manufacturing employees at or nearing retirement age, manufacturers report that recruiting is now 36% harder than it was in 2018. Since automotive is the largest manufacturing sector in the U.S., these trends are expected to hit the industry hard. In this environment, maintaining a clean, healthy and comfortable workplace can help manufacturers stay ahead in the competition for manufacturing talent.

Regulatory compliance is another reason for automotive manufacturers to invest in industrial air filtration. The Occupational Safety and Health Administration (OSHA) regulates the quality of the air that workers breathe. Manufacturers must comply with OSHA’s “General Duty Clause” to provide a workplace that is safe and healthy. Welding facilities, in particular, must comply with air contaminant requirements that address permissible exposure levels (PELs) for specific toxic substances, such as manganese and hexavalent chromium.

Related Resources

SOLUTIONS FOR DUST AND FUMES IN THE AUTOMOTIVE INDUSTRY

RoboVent understands the workflows, processes and challenges of automotive parts manufacturing. Our air quality solutions are designed to make your facilities safer, healthier and more efficient—while working within your space and budget constraints. We’ve put a lot of thought into details like space-saving design, integrated fire safety and automated controls that let your fume and dust collectors practically take care of themselves.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.