WHAT ARE PLEATED CARTRIDGE AIR FILTERS?

Pleated cartridge air filters, also known as dust collector cartridge filters, are specialized industrial air filters designed to capture and contain dust, particulates, and contaminants in various industrial applications. They are consumable filters designed for use in cartridge dust collectors, which are among the most common dust collector types for industrial air filtration. Cartridge dust collectors typically use several air filter cartridges, which are replaced when they become loaded.

Pleated cartridge air filters, also known as dust collector cartridge filters, are specialized industrial air filters designed to capture and contain dust, particulates, and contaminants in various industrial applications. They are consumable filters designed for use in cartridge dust collectors, which are among the most common dust collector types for industrial air filtration. Cartridge dust collectors typically use several air filter cartridges, which are replaced when they become loaded.

Pleated cartridges get their name from their unique design: multiple pleats of filter media are arranged around a cylindrical core, maximizing the filter media surface area. This allows for a high filtration efficiency while maintaining optimal airflow.

ADVANTAGES OF PLEATED CARTRIDGE FILTERS

The pleated cylindrical design of industrial dust collector cartridge filters provides significant advantages, especially when it comes to dust collector size. Pleated filters pack more filter media into a smaller space, which means the dust collector can be smaller, too. The pleated design is the main reason that cartridge dust collectors are generally smaller and more energy-efficient than other types, such as baghouse dust collectors. Cartridge filters have other advantages, too.

- Filtration efficiency: Cartridge air filters are available in a range of different filtration efficiency ratings and media types, making them suitable for a wide variety of dust collection applications.

- Easy maintenance: Cartridge filters are usually simple to install and change. Some cartridge dust collectors, such as RoboVent Senturion® and RoboVent Spire®, have features that allow for fast, easy filter change-outs without entering the dust collector chamber.

- Filter lifespan: Because pleated cartridge filters have more filter media per cartridge, they are able to collect more particulate before they need to be changed. That means longer service intervals and less downtime.

- Cost: Cartridge air filters, especially high-quality pleated filters, may cost a little more up front compared to simpler air filters. However, their extended filter life and efficiency lead to lower operating costs overall.

APPLICATIONS FOR INDUSTRIAL DUST COLLECTOR CARTRIDGE FILTERS

Cartridge filters are mainly used for collection of dry particulate, ranging from heavy abrasive dust to ultrafine dust and powder and submicron fumes from welding and other thermal processes. Pleated cartridge filters are suitable for a wide range of industrial applications, including:

- General manufacturing

- Bulk & powder applications

- Paper, cardboard and bookbinding

- Fabrication and metalworking (including weld fume collection)

- Food processing and baking

- Pharmaceuticals and nutraceuticals

- Battery manufacturing

- Electronic manufacturing

- Plastic manufacturing & FRP

- Mineral processing

- Woodworking

PLEATED AIR CARTRIDGE FILTER FEATURES

There are many different types of pleated dust collector cartridge filters on the market today. Understanding the options will help you choose the right industrial cartridge filter for your application. Choosing the right type of cartridge filter media will help you extend the life of your cartridge filters.

Media Type

Cartridge filters are available in a variety of media types, each tailored with specific characteristics to trap distinct types of dust particles.

- Cellulose: A conventional filter medium, cellulose is economical and suitable for numerous standard tasks. These cartridges typically have a MERV rating of 10-12 (see below). However, they might not be the top choice in terms of efficiency or durability, especially for intense industrial uses.

- Cellulose-Polyester Blend: Combining cellulose with synthetic fibers boosts the filter’s resilience, structure and strength. These filters often offer enhanced filtration efficiency (higher MERV ratings) and better performance for small particulates.

- Spunbond Polyester: Renowned for its durability, this filter medium stands up well against various challenges, including certain chemicals, elevated humidity, and higher temperatures. Additional coatings can further amplify its efficacy. Some spunbond polyester filters are also washable for a limited number of times under some usage scenarios.

- Nanofiber: Constructed from exceedingly fine fibers, nanofiber filter media is generally a slender layer atop a foundational material, such as a cellulose polyester blend or 100% polyester. While the nanofiber stratum ensures efficient small particle capture, the foundational layer offers the necessary structural integrity. Nanofiber is a great choice when high filtration efficiency is needed, especially for submicron particles.

Coatings and Specialty Features

In addition to the base filter medium, cartridge filters may come with various coatings or other special properties. Here are some specialty cartridge filter coatings and features to look for.

- PTFE-Coated: PTFE (Polytetrafluoroethylene) is a type of plastic that can be formed into a thin membrane with very small pores. PTFE-coated filters provide high filtration efficiency and excellent moisture and chemical resistance. They also improve the filter’s ability to shed dust (including moist or sticky dust), which extends filter life. PTFE-coated filters may be recommended for moist, oily, sticky particulate.

- Oleophobic media: Used for moist or oily dust, oleophobic filters are treated with special coatings or chemicals designed to repel oil and other hydrophobic substances, such as a fluoropolymer, silicone or nanoscale coating. These treatments allow the filter to repel oil and shed oily particulate more easily. Note: Oleophobic cartridge filters are used in applications when particulate is mixed with a small amount of oil; an oil mist collector must be used for applications producing significant mist from metalworking fluids (MWFs) or lubricants.

- Anti-Static Filters: These filters are designed to reduce the buildup of static electricity, which can be a concern in applications involving combustible dust. They typically feature a special coating or are made from conductive fibers. For example, cellulose filters may be carbon impregnated, while spunbond polyester may be carbonized or aluminized.

- Flame retardant: Flame-retardant cartridge filters are usually impregnated with a chemical that inhibits the combustion process to slow the spread of a fire within the dust collector filter chamber. They may be recommended when working with combustible or flammable particulate or in environments where there is a high risk of a spark entering the filter chamber. (Note: filters are fire retardant, not fireproof.)

Filtration Efficiency

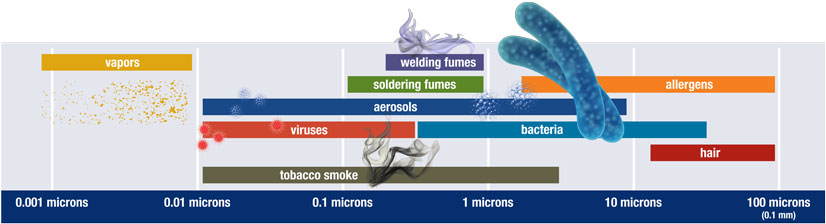

Filtration efficiency refers to a filter’s ability to capture and retain particles from the air passing through it. It represents the proportion of particles (of a particular size) that the filter can remove from the air. The higher the filtration efficiency, the better the filter is at capturing smaller particles. Dust collector cartridge filters are usually rated using the MERV (Minimum Efficiency Reporting Value) rating system, which classifies filters based on their ability to capture particles in different size bands (3 to 10 microns, 1 to 3 microns, and 0.3 to 1 microns). The higher the MERV rating, the better the filter is at capturing smaller particulate.

Industrial cartridge air filters are usually rated between MERV 11 and MERV 15, with some as high as MERV 16. The recommended MERV rating for industrial air filtration depends on the particle size distribution (large, coarse particles vs. submicron particles) and air quality requirements for the application.

- MERV ratings of 11-12 are suitable for larger particle sizes and less toxic applications (e.g., woodworking, manual metal grinding or cutting, abrasive blasting, non-toxic powder & bulk applications).

- For submicron particles produced by thermal processes like welding, a cartridge filter with a MERV rating of 15 or higher is usually recommended.

- Note that as a dust cake builds on the filter media, all cartridge filters will approach a filtration efficiency of MERV 16. However, when filtering fine and potentially hazardous particulate, it is important to choose a filter that will provide an appropriate level of filtration across the entire filter life.

- Applications with very fine submicron particulate, fumes or vapors and/or highly toxic materials may require a HEPA or activated carbon after filter.

When choosing a MERV rating for an industrial cartridge filter, always consider the specific dust challenges of your environment. Additionally, while a higher MERV rating means better filtration efficiency, it can also result in increased airflow resistance, which can impact energy consumption and filter lifespan. Therefore, it’s essential to balance efficiency with operational costs and filter performance.

Construction and Pleat Design

The quality of a cartridge dust collector filter directly impacts its performance and efficiency. High-quality filters not only provide superior filtration, but they also last longer, require less maintenance, and provide better overall value over their lifetime. In addition to filter media type and MERV rating, consider the following.

- Filter construction: Look for filters that are well-constructed with sturdy materials. This includes the filter’s end caps, gaskets, and liners. High-quality filters are built to withstand heavy use and prevent leaks past the filters.

- Pleat design: The pleats in a cartridge filter increase the surface area available for filtration. A high-quality filter will have a consistent and uniform pleat design, which promotes better airflow and dust release during cleaning. Optimal filter spacing makes more of the filter media usable, so each filter lasts longer and captures more particulate. Innovative pleat design also allows more filter media to be packed into a smaller space, which translates to a smaller overall dust collector size per CFM.

CARTRIDGE AIR FILTER SIZING AND CONFIGURATION

Different cartridge dust collectors require filters with different sizes and configurations. When buying cartridge dust collectors, it is important to make sure they are sized and configured correctly for your dust collector. Here’s what you need to know before ordering.

Size

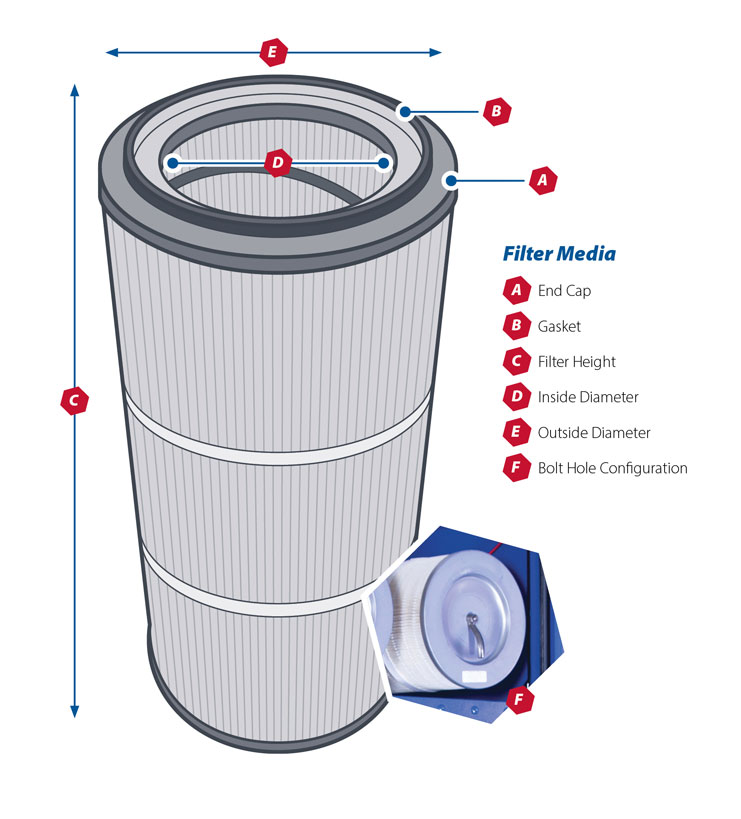

Be sure to measure all of the following.

- Filter Height/Length (measured from the bottom cap to the top cap)

- Inside cartridge diameter (ID) (distance across the round opening of the filter cartridge, from inside edge to inside edge)

- Outside cartridge diameter (OD) (distance across the filter, measured from the outside of the filter media)

End Cap Configuration

The end cap for a cartridge filter helps to ensure cartridge integrity and shape. The end cap generally has a gasket, which provides a seal within the collector, preventing any bypass of unfiltered air. The top cap may be circular, oval or another shape. Some cartridge dust collector filters also have a flange. When purchasing aftermarket replacement cartridge filters, you will need to get the exact dimensions of the flange if one is present.

It is important to choose the right end cap configuration for your cartridge dust collector. Common configurations include:

- Open/Open (OO) End Caps: Both ends of the cartridge filter are open. This configuration allows air to flow through both ends.

- Open/Closed (OC or CO) End Caps: One end of the cartridge filter is open, allowing airflow, while the other end is closed, typically with a solid metal or plastic cap. It is common in many dust collector systems where air enters from one end of the cartridge and exits out the other.

- Open/Threaded (OT) End Caps: One end of the cartridge filter is open, and the other end is threaded. The threaded end allows the filter to be screwed into or onto a fixture.

- Conical: The conical cartridge filter usually tapers from a larger diameter at one end to a smaller diameter at the other.

WHERE TO BUY PLEATED CARTRIDGE FILTERS FOR DUST COLLECTION

Choosing the right industrial pleated cartridge filter is important to ensure that your facility meets air quality goals and OSHA PELs while optimizing the energy efficiency of your dust collection system. RoboVent can help you find the best pleated cartridge filter for your application.

At RoboVent, we manufacture our own high-quality replacement cartridge filters for dust collection systems, including aftermarket cartridge filters for most makes and models of industrial dust collectors.

Our Endurex RMO™ and PleatLock™ cartridge filters are engineered for high performance.

- Endurex RMO cartridge filters are an economical and versatile pleated cartridge air filter suitable for a range of applications, including fumes, smoke, dust, oil haze, and other particulate. Mini-pleats with RMO support for optimal filter spacing. Available ratings up to MERV 16. Compared to PleatLock cartridge filters, Endurex filters have fewer pleats per inch and wider spacing between pleats. Recommended for large particles or fibrous applications.

- PleatLock cartridge dust collector filters have an innovative pleat design engineered with 35% more filter media within the cartridge to extend filter life. This filter technology provides longer intervals between filter changes, less downtime for maintenance and greater savings on the cost of replacement filters. Cellulose polyester blends in MERV 11, MERV 15 and MERV 16.

NEED HELP CHOOSING REPLACEMENT CARTRIDGE AIR FILTERS?

Contact our team for advice on cartridge filter selection.