INTRODUCTION TO DUST CONTROL FOR FOOD PROCESSING INDUSTRIES

The food processing industry as a whole produces many different types of dust. Some of the most common food processing dust types include fugitive grain dust from silo filling and grain transport; grain and flour dust from milling and grinding; corn starch and other powdered starches; dust from transporting or grinding dried nuts and legumes; dehydrated milk and egg products; sugar dust; and cocoa dust. The food processing industry also uses a wide variety of spices, flavorings and additives, some of which are hazardous in the concentrations workers are exposed to during food production.

The food processing industry as a whole produces many different types of dust. Some of the most common food processing dust types include fugitive grain dust from silo filling and grain transport; grain and flour dust from milling and grinding; corn starch and other powdered starches; dust from transporting or grinding dried nuts and legumes; dehydrated milk and egg products; sugar dust; and cocoa dust. The food processing industry also uses a wide variety of spices, flavorings and additives, some of which are hazardous in the concentrations workers are exposed to during food production.

Dust control for food processing is important from both a food safety perspective and a worker health and safety perspective. Uncontrolled food dusts create many different types of problems, including sanitation concerns, cross-contamination, microbial contamination, health issues for workers and slip-and-fall hazards. Dust control is also a regulatory consideration for food processors, who must comply with stringent food safety regulations from the FDA and USDA as well as occupational safety regulations from OSHA and NFPA. Failure to properly control food processing dust can expose companies to substantial fines, a greater risk of food recalls and even loss of FDA registration.

There are 32,000 food processing facilities in the U.S. alone, ranging from tiny local and regional bakeries to mega-processing plants employing up to 5,000 workers—and each one of these facilities has unique needs when it comes to dust control. Because the exact hazards and conditions vary so widely across the different parts of the food processing industry, mitigation solutions for food processing dust must be designed for the specific dust types, processes and environmental conditions at each facility. It is important to work with an engineering partner who can develop a holistic dust control solution that includes ventilation, dust containment and dust collection.

Related Resources

DUST CONTROL SOLUTIONS FOR FOOD PROCESSING INDUSTRY

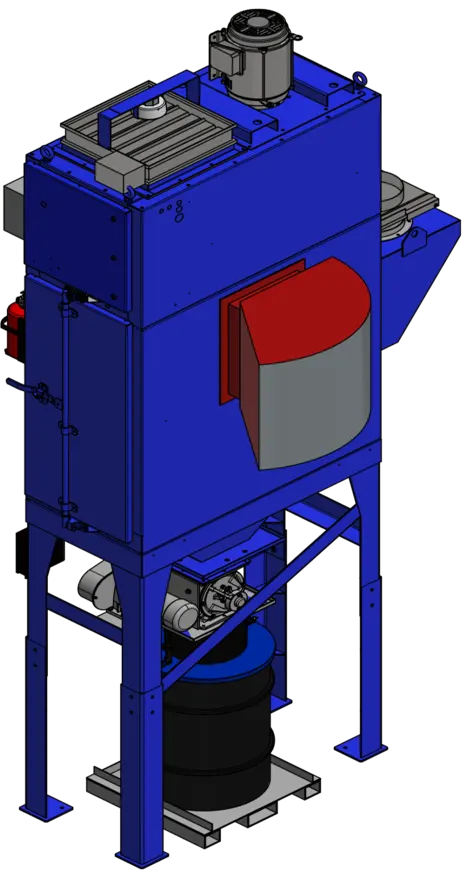

RoboVent offers robust and innovative dust control solutions for all stages of food processing, including silo filling and dry mix, processing and packaging. We understand the regulatory pressures you are under and will help you design a system that will meet your needs.

Dust collection for food processing dust is not “one size fits all.” Our engineers will evaluate your processes and help you select the right dust collector and filter media. We can also design an industrial ventilation and makeup air solution for you to ensure optimal dust collection, reduce cross-contamination concerns and mitigate health and safety hazards.

RoboVent can also help you meet OSHA and NFPA regulatory requirements and safety guidelines for management of combustible dusts. We can conduct a dust hazard analysis (DHA) for your operations under the NFPA Combustible Dust Standard (NFPA 652) and put dust control systems in place to mitigate the risks of a combustible dust explosion from food processing dust.

Our experienced air quality engineers will work with you through the whole process, including needs analysis, system design and engineering, collector and ductwork installation, filter selection, HVAC system integration, startup and commissioning, and aftercare and service.

Bulk food ingredient handing encompasses the front end of the food processing industry, where raw grains and other bulk ingredients are transported by truck or rail car, pneumatically conveyed into silos for storage, moved via conveyors or high-velocity pipes, and dry mixed.

The middle stage of the food processing industry is where bulk ingredients are transformed into edible products. During the processing stage, food manufacturers prepare and combine ingredients and add flavorings and additives such as stabilizers and preservatives.

Dust collection and containment for food packaging lines is critical. At this stage, the finished food product is packaged for sale and consumption. At the packaging stage, cleanliness is especially important to prevent contamination and ensure that the finished package is clean, sanitary and appealing for consumers.

DUST COLLECTION CHALLENGES FOR THE FOOD PROCESSING INDUSTRY

The food processing industry faces several challenges when it comes to dust control. The exact risks and challenges depend on the ingredients and processes used. Most dust created by the food industry isn’t considered to be toxic or dangerous—after all, these are products intended to be ingested. But that doesn’t mean dust control isn’t important.

DUST CONTROL REGULATIONS FOR THE FOOD PROCESSING INDUSTRY

The food processing industry is highly regulated. The Food and Drug Administration (FDA) is primarily concerned with food safety issues, including issues related to cross-contamination and microbial contamination, while the Occupational Safety and Health Administration (OSHA) develops regulations related to worker safety. Food processors also have to follow OSHA and National Fire Prevention Association (NFPA) standards for combustible dusts.

CONSIDERATIONS IN SELECTING A DUST CONTROL SOLUTION FOR FOOD PROCESSING DUST

Engineering controls for food processing dust will generally include a mix of containment, ventilation and dust collection/filtration solutions. While the exact solution will vary depending on the dust type, specific processes, and layout of the facility and production lines, there are some general principles that apply across the food processing industry.

DUST CONTROL SOLUTIONS FOR THE FOOD PROCESSING INDUSTRY

RoboVent offers robust and innovative dust control solutions for all stages of food processing, including silo filling and dry mix, processing and packaging. We understand the regulatory pressures you are under and will help you design a system that will meet your needs.

Dust collection for food processing dust is not “one size fits all.” Our engineers will evaluate your processes and help you select the right dust collector and filter media. We can also design an industrial ventilation and makeup air solution for you to ensure optimal dust collection, reduce cross-contamination concerns and mitigate health and safety hazards.

RoboVent can also help you meet OSHA and NFPA regulatory requirements and safety guidelines for management of combustible dusts. We can conduct a dust hazard analysis (DHA) for your operations under the NFPA Combustible Dust Standard (NFPA 652) and put dust control systems in place to mitigate the risks of a combustible dust explosion from food processing dust.

Our experienced air quality engineers will work with you through the whole process, including needs analysis, system design and engineering, collector and ductwork installation, filter selection, HVAC system integration, startup and commissioning, and aftercare and service.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.