Retractable Industrial Enclosures

DuroRoom™ is a flexible process containment system engineered to accommodate large parts, overhead crane use and dynamic industrial workflows.

- Retracts to 20% of full length for overhead crane access and space savings

- Modular, code-compliant construction adapts to any workspace or process

- Engineered for clean, controlled environments across diverse manufacturing operations

Support Manufacturing Productivity, Compliance and Safety with Flexible Process Containment

Make your facility healthier and more productive by containing dust-, fume- and mist-generating processes, keeping the air cleaner and your environment safe and compliant. Retractable industrial enclosures offer a modular, cost-effective solution for managing dust, fumes and overspray in challenging industrial environments.

- Improved Air Quality: Contain contaminants at the source to prevent fume propagation through the facility and support regulatory compliance.

- Flexible Containment: DuroRoom retracts to just 20% of its full length, reclaiming floorspace or allowing crane access. Within the enclosure, additional separation can be created for smaller parts or sub-processes, allowing multiple operations to run at once without cross-contamination.

- Ideal for Oversized Parts: Easily enclose large or irregularly shaped equipment and components that don’t fit in standard hoods or booths, from airplane engines and fuselages to wind turbines and blades.

- Fast, Easy Setup: Modular design installs quickly with minimal facility disruption; more cost-effective and adaptable than constructing permanent enclosures or booths.

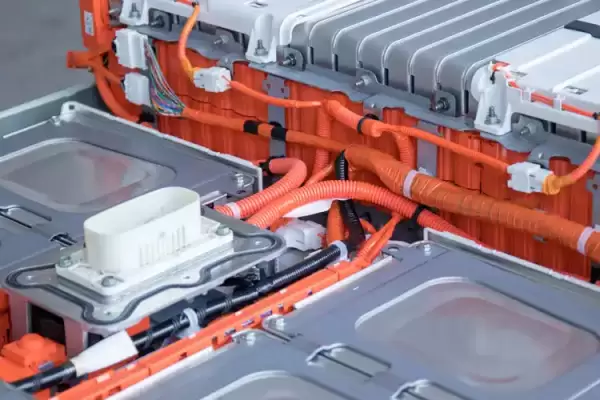

- Integrated Dust Collection: Available with integrated dust collection and filtration for a complete clean air solution.

- Customizable: Configure for your process, space and equipment, with sizes up to 50’ high and 65’ wide and unlimited length.

Key Features

Designed for demanding manufacturing environments, the DuroRoom™ industrial enclosure system combines heavy-duty construction with smart engineering to deliver clean, compliant air wherever it’s needed. Each system is built to your specifications for reliable performance, easy operation and long-term durability.

- Retractable Design: Reduces to 20% of full length to allow overhead crane access, easier material handling and efficient use of floor space.

- Modular Construction: Built in 5' or 6' increments for custom sizing, fast installation and easy future reconfiguration. Up to 50’ high and 65’ wide with unlimited linear length.

- Taper Draft airflow: Maintains consistent cross-draft airflow to control contaminants and improve coating or finishing quality.

- Custom Pressure Control: Configurable for positive, negative or neutral pressure to meet specific process and safety requirements.

- Heavy-Duty Steel Structure: Galvanized or powder-coated construction ensures long-term durability in demanding industrial environments.

- NFPA 701–Compliant Vinyl Covering: Flame-retardant, UV-, rot- and mildew-resistant materials maintain visibility and performance.

- Quick-Seal Penetrations: Allow clean, sealed entry points for air, electrical and mechanical connections.

- Integrated Fire Suppression: Kidde Badger system protects both the enclosure and exhaust as the unit extends and retracts.

- Lighting Options: Available in C1D1, C1D2 or LED configurations; clear vinyl provides 95% light transfer for excellent illumination.

- Optional Cleanroom Configuration: Supports ISO-level cleanliness for sensitive manufacturing or testing applications.

Applications for Retractable Process Enclosure Systems

This tough retractable industrial enclosure system is engineered for process containment in a wide range of manufacturing environments where flexibility, cleanliness, and compliance are critical. Its retractable design makes it ideal for large-part production, maintenance and finishing operations that require overhead crane access or frequent workflow changes.

Composite and Fiberglass Fabrication: Create enclosed, ventilated areas for manufacturing and finishing of boat, pools, and large composite structures.

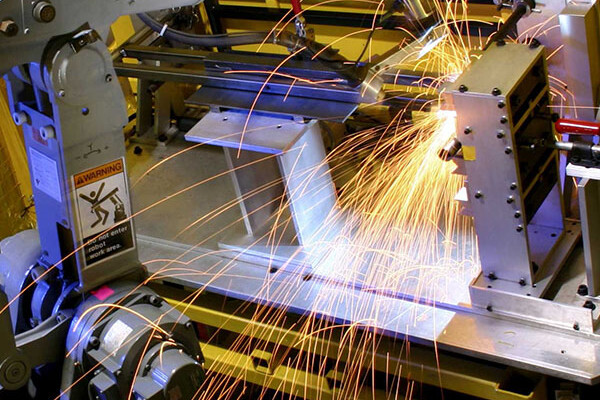

Sanding and Grinding: Capture airborne dust and debris to protect operators and improve product finish.

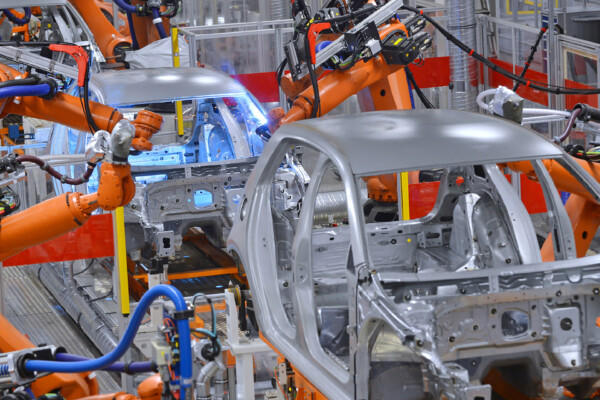

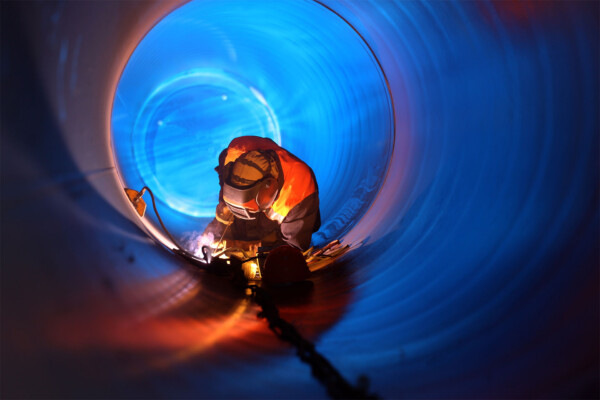

Welding and Fabrication: Enclose large or complex weldments requiring long cycle times to contain fumes, support crane access, and maintain compliant air quality.

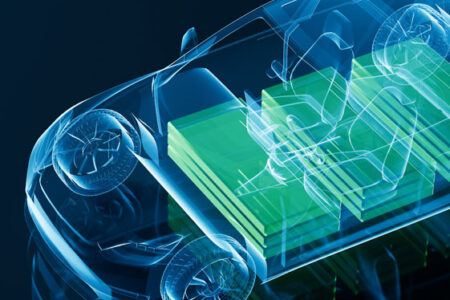

Infrastructure and Renewable Energy Components: Enclose oversized parts such as wind turbine blades, towers, and other large structures for controlled sanding, coating, or finishing.

Large-Part Assembly and Finishing: Support cranes, lifts, and heavy equipment with a retractable, open-access design.

Aerospace and Defense Manufacturing: Maintain strict air quality and contamination control during precision work.

Equipment Maintenance and Repair: Create portable enclosed workspaces for servicing vehicles, aircraft, and machinery on manufacturing floors, airports, and military bases.

Thermal Lancing and Hand Plasma Cutting: Contain sparks, hot slag, and heavy fumes generated during high-heat cutting operations.

Frequently Asked Questions

DuroRoom

Where can retractable process enclosures be installed?

Retractable industrial enclosure systems can be installed on factory floors, in hangars, maintenance facilities and even used as portable or temporary structures. Their retractable, modular design makes them ideal for environments that require frequent changeovers or mobility.

What sizes are available for industrial process enclosures?

Standard retractable enclosure systems can reach up to 50 feet high and 65 feet wide, with unlimited linear length. Each unit is custom-built to fit your process, workpiece, and facility layout.

Do retractable process enclosures require ductwork or makeup air?

In many cases, no. When paired with the appropriate filtration system, industrial hoods and enclosures can operate as a recirculating clean-air enclosure, reducing or eliminating the need for external ducting and saving energy costs.

Can DuroRoom be used as a cleanroom or testing environment?

Absolutely. When equipped with vinyl coverings and proper filtration, DuroRoom can achieve positive or negative pressure environments suitable for ISO-level cleanrooms or controlled testing spaces.

Do DuroRoom systems meet safety and air quality standards?

Yes. Every DuroRoom is engineered to comply with OSHA, NFPA and NESHAP air quality and fire safety standards. Vinyl coverings meet NFPA 701 flame-retardant requirements, and fire suppression systems are designed by Kidde Badger for industrial environments.

Can enclosures be customized?

Yes. These modular industrial enclosures are modular and built in 5' or 6' increments to meet specific workspace requirements. Options include positive, negative, or neutral pressure configurations; various door and curtain styles; and custom lighting, fire suppression and cleanroom setups.

What industries use retractable process enclosures?

Retractable industrial enclosures are used across aerospace, defense, transportation, heavy equipment and general manufacturing industries. Common applications include painting and coating, sanding and grinding, non-destructive testing and enclosed maintenance bays on factory floors or at military bases.

How do retractable industrial enclosures improve manufacturing flexibility?

This flexible process enclosure retracts to 20% of its full length, allowing easy overhead crane access, material handling and equipment movement. This makes it ideal for large-part manufacturing, vehicle and aircraft maintenance, and other operations where space and workflow flexibility are critical.

DROP US A LINE

Contact RoboVent today to start building your custom dust collection system.