SOLUTIONS FOR DUST AND FUME CONTROL IN HEAVY EQUIPMENT MANUFACTURING

Heavy equipment manufacturing or repair require heavy-duty dust collection solutions.

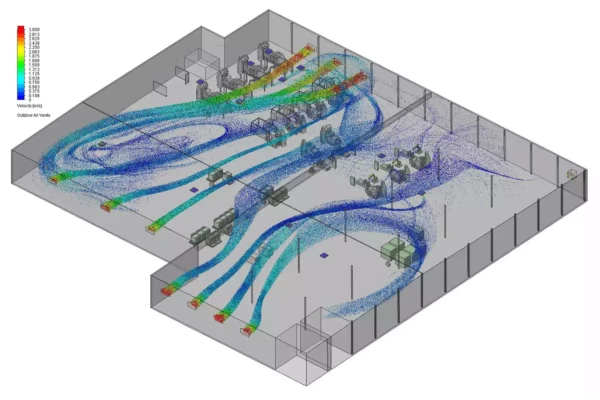

Heavy equipment production involves large components, multiple fabrication zones and mixed operations—often in facilities that must accommodate cranes, mobile welders and large-scale material handling. RoboVent designs dust collection systems to match those conditions. Whether you’re building out a new plant, upgrading an aging facility or retrofitting a specific process, we can help you engineer a custom solution.

RoboVent’s world-class equipment is built tough to withstand any dust, fume or mist collection challenge in the heavy equipment industry. From manual and robotic welding to plasma cutting and thermal lancing, we have solutions that fit your processes and facility. Our Senturion® cartridge dust collector is built for the heavy particulate loads common in welding, cutting and grinding operations for heavy equipment manufacturing, while Clarion® will take care of oil mists from metalworking and fabrication processes. For ambient air filtration, RoboVent Vortex® offers unmatched flexibility in open production spaces, and our VentMapping® computer-aided engineering process ensures each system is designed with your layout, airflow and compliance needs in mind.

Related Resources

PROCESSES IN HEAVY EQUIPMENT MANUFACTURING

Dust and fume generation in heavy equipment manufacturing comes from a wide range of processes, often performed on large, heavy-gauge materials with minimal containment or local ventilation. Each of these processes presents unique air quality risks that must be addressed with a system tailored to your operations. Common operations include:

AIR QUALITY CHALLENGES IN HEAVY EQUIPMENT MANUFACTURING

The physical demands of heavy equipment production—large parts, open layouts, mobile work—make air quality control more complex than in traditional small parts manufacturing. Some of these challenges include:

HEALTH AND SAFETY CONSIDERATIONS

Heavy equipment manufacturing often takes place in large, open industrial environments—such as construction equipment plants, railcar assembly facilities and fabrication shops—where exposure risks are elevated due to the scale of components, mobile workstations and limited containment. Workers regularly face visual and auditory stressors from welding arcs, plasma cutting, and grinding, along with thermal hazards such as molten metal, slag and hot surfaces.

REGULATORY COMPLIANCE IN HEAVY EQUIPMENT MANUFACTURING

Manufacturers must meet a wide range of regulatory standards to maintain compliance and reduce liability.

CONSIDERATIONS IN DUST AND FUME CONTROL SYSTEM DESIGN

Large-scale manufacturing environments come with unique challenges—and require systems built to scale, withstand heavy use, and adapt to changing workflows.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.