Hexavalent Chromium: What Welders Need to Know

Hexavalent chromium—also known as hex chrome or Cr(VI)—is a common byproduct of welding stainless steel and a significant health hazard for welders. Welders engaged in stainless steel welding need to understand their exposure risks and take steps to protect themselves.

What is Hexavalent Chromium?

Hexavalent chromium, denoted as Cr(VI), is one of the valence states (+6) of the element chromium (Cr). The valence state (or oxidation state) of an element describes the degree of oxidation of an atom in a chemical compound. In simple terms, the valence state indicates the “combining power” of an element when it interacts with other elements in chemical reactions. Chromium is a transition metal that exhibits several oxidation states, the most common being:

Hexavalent chromium, denoted as Cr(VI), is one of the valence states (+6) of the element chromium (Cr). The valence state (or oxidation state) of an element describes the degree of oxidation of an atom in a chemical compound. In simple terms, the valence state indicates the “combining power” of an element when it interacts with other elements in chemical reactions. Chromium is a transition metal that exhibits several oxidation states, the most common being:

- +2 (divalent)

- +3 (trivalent)

- +6 (hexavalent)

Hex chrome is usually produced industrially by anodic oxidation of trivalent chromium. It is also a common byproduct of welding stainless steel and other thermal processes involving chromium-containing metals. Unlike the less toxic trivalent chromium (Cr(III)), Cr(VI) is known to be highly toxic and can pose serious health risks with exposure.

How Hex Chrome is Formed

Hexavalent chromium is produced by oxidation of other forms of chromium, such as CR(III). During the welding process on stainless steel or other chromium-containing metals, the high temperatures cause the chromium present in the metal to oxidize. This oxidation process can produce hexavalent chromium fumes. Factors that can increase Cr(VI) formation in weld fumes include:

- The welding method used (some methods produce more fumes than others)

- The amount of chromium in the metal being welded

- The presence of contaminants or other metals

- The temperature and duration of the welding process

Other processes that may produce CR(VI) fumes include:

- Thermal cutting

- Smelting

- Chrome plating

- Thermal spraying

- Printing

- Incineration/recycling of chromium-containing waste products

- Glass manufacturing (when using lead chromate materials)

- Chemical manufacturing (especially dyes, paints and pigments)

Does All Stainless Steel Contain Hexavalent Chromium?

Stainless steel does not typically contain hexavalent chromium initially. Stainless steel is an alloy made up of iron, chromium, and other elements. However, the chromium in stainless steel is in its trivalent state (Cr(III)). It’s the welding process, especially when done at high temperatures, that can oxidize the trivalent chromium into the hexavalent state, releasing Cr(VI) fumes. Therefore, any stainless steel has the potential to produce hexavalent chromium when subjected to welding or other thermal processes.

Stainless steel alloys typically contain between 10-30% chromium. Many tool steels, especially high-speed steels, contain chromium to enhance their hardness and wear resistance. It’s important to know the chromium content in the metal being welded, as higher chromium content could lead to greater Cr(VI) exposure.

Stainless steel is not the only metal alloy that contains chromium. Other chromium-containing alloys include ferrochromium (iron and chromium), nichrome (nickel and chromium), and certain alloys of aluminum, titanium, and other metals. Chromium is added to metal alloys to improve strength and corrosion resistance.

Other Products Containing Hexavalent Chromium

Hexavalent chromium is used in various industrial applications due to its anti-corrosive properties. It’s often used in paints, inks, and other surface coatings. Hex chrome is commonly found in:

- Paints and primers (especially in the automotive and aerospace industries)

- Dyes and pigments

- Leather tanning agents

- Chrome plating

- Anti-corrosion products

Exposure Risks of Hexavalent Chromium

While chromium in its natural state plays a vital role in human metabolism, its hexavalent form has raised health alarms due to its high toxicity when inhaled or ingested. Hex chrome health effects include lung damage and cancer, skin irritation, stomach ulcers, and developmental and reproductive problems.

What makes hex chrome so dangerous? The heightened toxicity of hexavalent chromium primarily stems from its high oxidizing potential and its ability to penetrate cells. Once inside the body, Cr(VI) is reduced to its trivalent form, Cr(III), releasing reactive intermediates that can damage DNA and other cellular components. This damage is linked to its carcinogenic, mutagenic, and teratogenic (fetal development) effects.

How Hexavalent Chromium Impacts the Body

When Cr(VI) compounds are inhaled, ingested, or come in contact with the skin, they pose several risks.

- Respiratory System: Inhalation of Cr(VI) particles can lead to lung damage, chronic bronchitis, occupational asthma, and nasal septum ulcerations and perforations.

- Digestive System: Ingestion can lead to stomach ulcers and disruptions in gastrointestinal function.

- Dermatological Effects: Direct skin contact with CR(VI) may cause skin ulcers and allergic contact dermatitis.

- Cancer Risk: Hex chrome is a well-known carcinogen and has been linked to several forms of cancer. Welders inhaling hex chrome fume are at heightened risk of lung cancer. Hexavalent chromium has also been linked to nasal and sinus cancer and stomach cancer.

- Kidney and Liver: The liver and kidneys have a central role to play in breaking down and excreting toxins such as hex chrome. Cr(VI) is broken down into Cr(III) by the liver; chronic or high levels of exposure may lead to liver damage. Chronic exposure to Cr(VI) can also lead to nephrotoxicity (damage to the kidneys) and reduced kidney function.

- Developmental and Reproductive Effects: Hexavalent chromium exposure can have adverse effects on both development and reproduction. The effects span a range of concerns from embryonic development to fertility and are of particular importance for pregnant individuals and those planning a pregnancy. Pregnant workers exposed to hex chrome may be at higher risk for miscarriage, and there is evidence that exposure in the womb may cause fetal growth retardation, skeletal malformations, and neurological damage. Men exposed to high levels of hex chrome fumes may experience a decline in sperm count and an increase in sperm abnormalities.

Symptoms of Hexavalent Chromium Exposure

The symptoms resulting from Cr(VI) exposure can vary based on the route and duration of exposure.

- Short-term exposure may result in irritation or damage to the nose, throat, and lungs (coughing or wheezing), a runny or itchy nose, skin rashes or contact dermatitis, or eye irritation.

- Long-term exposure is associated with chronic respiratory issues, permanent skin damage, stomach ulcers and other long-term health impacts.

It is important to note that many people do not have acute short-term effects from hexavalent chromium exposure. Many welders exposed to toxic levels of hex chrome in the workplace do not show immediate symptoms. That does not, however, mean that exposure is safe.

What to Do If You’ve Been Exposed to Hex Chrome

Employees experiencing acute symptoms of hexavalent chromium exposure should take steps to remove themselves from the exposure source and seek medical attention if symptoms are present. The incident should be reported to a workplace safety officer so remedies can be put in place to prevent future exposures. For employees who have experienced long-term exposure to hex chrome, a medical surveillance program should be put in place to monitor exposed employees for development of lung damage, cancer, stomach ulcers and other long-term effects. The most reliable way to test for hexavalent chromium exposure is through blood testing; chromium levels can also be measured in hair and urine.

Welding and Hexavalent Chromium Exposure

Welding stainless steel and other chromium-containing alloys is one of the most common exposure routes for hexavalent chromium. Welding exposes base metals to high heat, transforming less dangerous Cr(III) into highly toxic Cr(VI). Hexavalent chromium, while not present in the original base material, is a significant component of welding fumes created when welding stainless steel and other chromium-containing alloys.

Weld Fume Composition and Hexavalent Chromium

The exact amount of Cr(VI) in the welding fume varies based on several factors, such as the welding process, current settings, type of electrode used, and specific alloy of stainless steel. Studies have shown that the concentration of hexavalent chromium in weld fumes can vary dramatically depending on these factors. The best way to determine the concentration of weld fumes produced by a specific process or application is through air sampling and laboratory testing.

Factors Impacting Hex Chrome Exposure in Welding

Several factors influence the exposure levels to hex chrome during welding.

- Base materials: The higher the chromium content in the base metal, the more hexavalent chromium will be found in the weld fumes. Hex chrome is primarily associated with stainless steel welding, as stainless steel alloys typically contain 10-30% chromium. However, other alloys may also have chromium added. It is important to understand the chemical composition of the metals you are welding.

- Welding process: Different welding processes can produce different amounts of fumes and Cr(VI). For instance, shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW) have been noted to produce significant amounts of Cr(VI) when welding stainless steel.

- Duration and frequency of welding: Longer welding sessions and more frequent welding activities will generally result in increased cumulative exposure to Cr(VI), elevating the risk.

- Welding parameters: Higher welding currents and voltages can increase the amount of fumes generated and, consequently, the amount of Cr(VI) produced.

- Weld fume mitigation: The presence and effectiveness of air filtration and ventilation play a significant role in determining exposure levels. Local exhaust ventilation and source capture filtration solutions (such as fume arms, fume guns, backdraft plenums, or receiving hoods) can effectively reduce Cr(VI) concentrations in the immediate vicinity of the welders.

Permissible Exposure Limits for Hexavalent Chromium

Due to the recognized health hazards of hexavalent chromium, regulatory agencies like the U.S. Occupational Safety and Health Administration (OSHA) have established permissible exposure limits (PELs). The OSHA PEL for Cr(VI) for general industry (including welding and metalworking operations and general fabrication) is set at 5 micrograms per cubic meter (5 µg/m3) as an 8-hour time-weighted average (TWA). Employers are required to ensure that workers’ exposures do not exceed this limit, necessitating the use of engineering controls, work practices, and protective equipment in environments where hexavalent chromium exposure is a concern. OSHA has also set an Action Limit (AL) for hex chrome at 2.5 µg/m3, or half the PEL. If workplace monitoring reveals that the level of Cr(VI) exposure is at or above the Action Limit but below the PEL, it triggers certain obligations for the employer, such as medical surveillance, increased air quality monitoring and exposure testing, and implementation of engineering controls to keep exposure levels in check.

Due to the recognized health hazards of hexavalent chromium, regulatory agencies like the U.S. Occupational Safety and Health Administration (OSHA) have established permissible exposure limits (PELs). The OSHA PEL for Cr(VI) for general industry (including welding and metalworking operations and general fabrication) is set at 5 micrograms per cubic meter (5 µg/m3) as an 8-hour time-weighted average (TWA). Employers are required to ensure that workers’ exposures do not exceed this limit, necessitating the use of engineering controls, work practices, and protective equipment in environments where hexavalent chromium exposure is a concern. OSHA has also set an Action Limit (AL) for hex chrome at 2.5 µg/m3, or half the PEL. If workplace monitoring reveals that the level of Cr(VI) exposure is at or above the Action Limit but below the PEL, it triggers certain obligations for the employer, such as medical surveillance, increased air quality monitoring and exposure testing, and implementation of engineering controls to keep exposure levels in check.

Employers should also be aware of lower recommended exposure limits set by the National Institute of Occupational Safety and Health (NIOSH) and the American Conference of Governmental Industrial Hygienists (ACGIH). These organizations set recommended exposure limits based on scientific evidence; these recommendations do not have the force of law, but can be considered industry best practices. Both NIOSH and ACGIH have set recommended limits of just 0.2 µg/m3.

It is important to remember that the PEL for hexavalent chromium is much lower than the PEL for weld fume as a whole, currently set at 5 mg/m3—1,000 times higher than the hex chrome PEL. That is why it is critical for employers to understand the composition of their welding fumes and the individual PELs for toxic elements such as hexavalent chromium.

Protecting Welders from Hexavalent Chromium

To protect welders from the dangers of hexavalent chromium, employers need to implement stringent weld fume controls, including engineering controls such as air filtration and industrial ventilation.

When welding stainless steel and other chromium-containing alloys, the system must be designed to meet the stringent PELs set for hex chrome.

Source Capture Methods for Stainless Steel Welding

Source capture methods for welding should be used wherever possible when welding stainless steel. For manual welding, these might include:

- Fume extraction arms

- Welding tables with integrated fume extraction

- Backdraft plenums

- Fume guns/fume extraction torches

The source capture method should be chosen to minimize fumes in the welder’s breathing zone. In general, that means collecting fumes as close to the source as possible. When using a fume arm, for example, make sure it is placed directly over the seam so fugitive fume does not escape. Fume guns, when used properly, can collect as much as 90-95% of weld fumes as they are created. If using a backdraft plenum, make sure the placement and capture velocity are calibrated to keep fumes away from the welder’s face.

Robotic welding processes should be fully enclosed under a fume hood or otherwise isolated from the rest of the facility.

Ambient Fume Capture

Ambient capture is not recommended as a primary weld fume control method for stainless steel welding, because it does not keep rising fumes out of the breathing zone. However, if the primary source capture method does not capture 100% of fume, an ambient air filtration system can help facilities keep exposure levels below the PEL.

Exposure Testing

Whatever kind of weld fume extraction system is chosen, when working with hazardous emissions such as hexavalent chromium, it is advisable to conduct facility testing to ensure that the PEL is being met. The most accurate method of testing worker exposure levels is through personal sampling using a small device that pulls air through a filter. The device is usually clipped to the welder’s collar or lapel to measure exposure levels in the breathing zone. The filter is sent to a lab for analytical testing to determine exposure levels.

Should PPE be used when welding stainless steel?

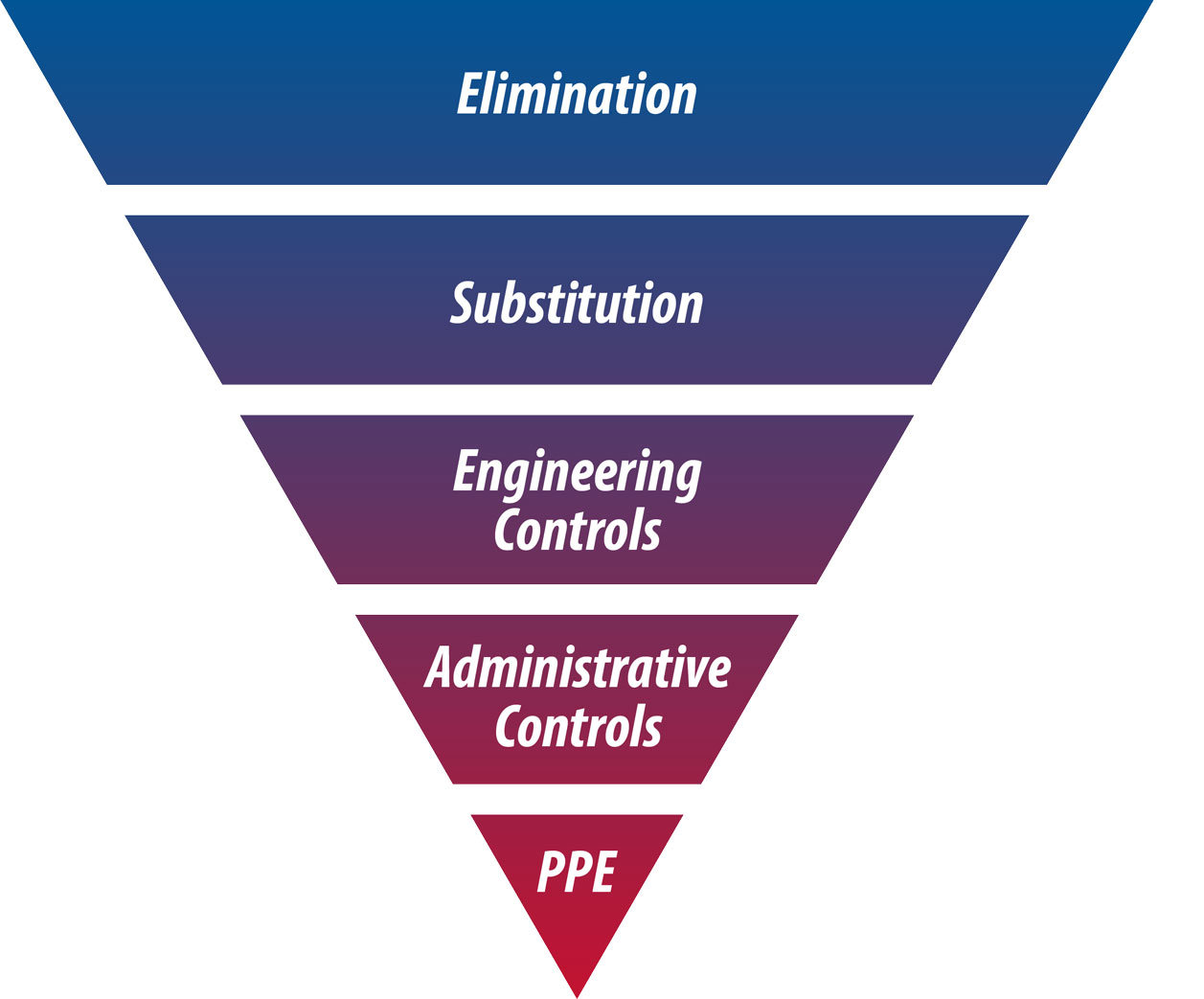

If engineering controls cannot adequately control fumes from stainless steel welding, it may be necessary to provide welders with appropriate respirators to reduce exposure to hexavalent chromium. This might range from disposable N95/KN95 masks to powered air-purifying respirators (PAPRs), depending on the level of exposure. However, keep in mind that respirators should not be the first or only line of defense from hex chrome in welding fumes. According to the hierarchy of controls, engineering controls such as air filtration and ventilation must be implemented before relying on PPE.

If engineering controls cannot adequately control fumes from stainless steel welding, it may be necessary to provide welders with appropriate respirators to reduce exposure to hexavalent chromium. This might range from disposable N95/KN95 masks to powered air-purifying respirators (PAPRs), depending on the level of exposure. However, keep in mind that respirators should not be the first or only line of defense from hex chrome in welding fumes. According to the hierarchy of controls, engineering controls such as air filtration and ventilation must be implemented before relying on PPE.

Want to know more about weld fume control? Check out the Complete Guide to Welding Fume Extraction Systems.

Contact Us With Your Questions!

SUBSCRIBE TO

BLOG UPDATES