Selecting a Welding Table with Fume Extraction: What to Know Before You Buy

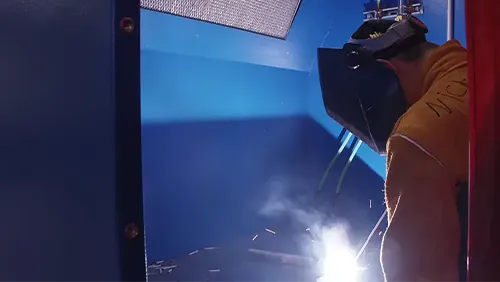

Welding tables with fume extraction are a simple and elegant solution for manual welding. Welders simply place their pieces on the built-in work surface, turn on fume extraction, and start welding. The right welding booth will create a safe, efficient and productive work environment. Here’s what you should know before purchasing a backdraft or downdraft table for weld fume extraction.

Welding tables with fume extraction are a simple and elegant solution for manual welding. Welders simply place their pieces on the built-in work surface, turn on fume extraction, and start welding. The right welding booth will create a safe, efficient and productive work environment. Here’s what you should know before purchasing a backdraft or downdraft table for weld fume extraction.

Is a Welding Table with Fume Extraction Right for You?

Welding tables with built-in welding fume extraction systems are a great option for many manual welding applications. Backdraft tables are one method of source capture solutions for welding fumes. They can be compared to competing options such as fume arms, fume guns or stand-alone backdraft plenums.

Advantages of Weld Tables with Built-in Fume Extraction

A source capture welding table works by pulling fumes away from the welder’s breathing zone as they are created. They offer many benefits for welders and fabrication shops.

- Ease of use: A welding table with fume extraction is an all-in-one solution, providing both an ideal work surface for manual welding and a built-in weld fume extraction system. Unlike fume arms, which require frequent repositioning to ensure that the extraction hood is placed directly over the weld seam, the intake plenum for an all-in-one welding table is positioned to effectively capture fumes from anywhere on the work surface.

- Space and cost savings: Welding tables with fume extraction eliminate the need for a separate dust collection system or ductwork. That can save both space and costs for small shops that just need a small number of stations for manual welding. (In larger shops with many welding stations or other dust collection needs, a centralized dust collection system may be a more cost- and energy-efficient option).

- Easy setup and installation: Most integrated weld booths are designed for plug-and-play operation: just connect to power (and to compressed air if needed for filter pulsing) and go. Since there is no ductwork to install, welding tables with fume extraction can be set up quickly and moved easily.

- Worker safety and compliance: Welding tables with fume extraction are a simple way to ensure compliance with OSHA PELs for weld fume. A properly designed backdraft table will pull fumes up and away from the welder’s breathing zone to minimize the health risks of weld fume exposure.

- Versatility: All-in-one welding booths are highly versatile. They can be used for most tabletop manual welding applications and fit easily into the shop environment. Unlike ducted stand-alone backdraft plenums or extraction hoods, they can be easily moved if the shop needs to be reconfigured.

Applications for Integrated Welding Booths

An integrated weld table with fume extraction is a great choice for many manual welding applications. Their simple setup and cost and space savings make them ideal for welding schools, smaller fabrication shops and other employers supporting a small handful of manual welders. Fume tables with backdraft extraction are best for:

An integrated weld table with fume extraction is a great choice for many manual welding applications. Their simple setup and cost and space savings make them ideal for welding schools, smaller fabrication shops and other employers supporting a small handful of manual welders. Fume tables with backdraft extraction are best for:

- Smaller weldments suitable for tabletop placement

- Stationary welding that does not require welders to move around

For welding applications requiring high welder mobility, high-production environments with many weld stations or high fume volumes, or applications producing highly toxic fumes, other source capture methods may be recommended.

Comparing Source Capture Options for Weld Fume

Welding benches with fume extraction are a simple and versatile source capture solution, but they are not the only option for manual welding. How do backdraft tables stack up against other weld fume control options like fume arms or fume guns? Other options may be recommended when:

- Weldments are too large or heavy to place on the work surface of the weld booth.

- Welders require a high degree of mobility to move around the part.

- The backdraft plenum for the weld table cannot keep concentrations of toxic fumes in the breathing zone below OSHA PELs

For example, in high-production welding of stainless steel, galvanized steel or other materials producing highly toxic fumes, it may be preferable to have fume extraction closer to the source of fumes.

- Fume arms can be positioned directly over the weld seam to collect fumes before they enter the breathing zone. A properly sized and placed fume arm is highly effective in capturing weld fumes and may require less airflow (lower CFM) than a backdraft plenum for a weld table. However, they must be repositioned frequently to make sure the capture hood is directly over the weld seam. Fume arms can be ducted to a centralized dust collection system or attached to a smaller stand-alone unit, such as the VentBoss Series S311.

Fume guns are a form of welding tip extraction that builds the extractor right into the weld torch. They are paired with a hi-vac extraction unit such as RoboVent ProCube™ II, Fume Eliminator, or RoboVent FlexPro™. A fume gun minimizes the airflow required for efficient weld fume capture and ensures that the capture system is always positioned at the weld seam. Fume guns are great for large weldments and applications requiring high mobility, since fume capture moves with the welder. When used properly, they collect 90% or more of weld fume as it is produced, keeping it out of the welder’s breathing zone. However, they can only be used with MIG welding, and capture efficiency is dependent on proper technique and positioning.

Fume guns are a form of welding tip extraction that builds the extractor right into the weld torch. They are paired with a hi-vac extraction unit such as RoboVent ProCube™ II, Fume Eliminator, or RoboVent FlexPro™. A fume gun minimizes the airflow required for efficient weld fume capture and ensures that the capture system is always positioned at the weld seam. Fume guns are great for large weldments and applications requiring high mobility, since fume capture moves with the welder. When used properly, they collect 90% or more of weld fume as it is produced, keeping it out of the welder’s breathing zone. However, they can only be used with MIG welding, and capture efficiency is dependent on proper technique and positioning.

What About Downdraft Tables?

Both backdraft and downdraft systems have been sold as “welding tables with fume extraction.” However, backdraft and downdraft fume extraction are not the same. Backdraft plenums are generally preferred for welding booths and weld tables with integrated fume extraction, especially in high-production environments.

Why? Because weld fume naturally rises. When using downdraft tables or benches, some of the rising fumes may escape the capture zone before it is collected. This fugitive fume ends up rising right into the breathing zone of the welder or escaping into the wider facility. Substantial airflow may be needed to maximize capture rates for rising weld fume when using downdraft tables. However, downdraft benches are usually highly effective at capturing heavier particulate from grinding or cutting. They may be suitable for lower-production welding or as a mixed-use workstation supporting multiple fabricating applications.

Backdraft tables, in contrast, work with the natural rising action of the weld fume for more efficient capture. A backdraft plenum pulls contaminants up and horizontally away from the breathing zone. This keeps fumes away from the welder’s face and prevents fugitive fume from escaping into the facility. However, a backdraft plenum may not be as effective for capturing heavy particulate that tends to fall.

When to Use a Centralized Weld Fume Collection System

All-in-one welding booths are an efficient and affordable weld fume control solution when supporting a small number of manual welding stations. But what about larger facilities? If you are supporting a dozen or more welders, have very high production operations, or are supporting other applications requiring dust control (such as robotic welding, laser cutting and grinding, etc.) in addition to manual welding, a centralized dust collection system may be more energy efficient and affordable in the long run. With a centralized system, individual welding booths and other dust-creating applications are ducted to a large centralized dust collector, which may be placed on the floor or outside the facility.

All-in-one welding booths are an efficient and affordable weld fume control solution when supporting a small number of manual welding stations. But what about larger facilities? If you are supporting a dozen or more welders, have very high production operations, or are supporting other applications requiring dust control (such as robotic welding, laser cutting and grinding, etc.) in addition to manual welding, a centralized dust collection system may be more energy efficient and affordable in the long run. With a centralized system, individual welding booths and other dust-creating applications are ducted to a large centralized dust collector, which may be placed on the floor or outside the facility.

A systems engineer can help you weigh the pros and cons of individual welding booths vs. a centralized dust collection system.

What to Look for in a Welding Table with Fume Extraction

When selecting a welding table with fume extraction, there are several features that can help to ensure maximum efficiency, minimum maintenance and effective fume extraction.

- Backdraft plenum: As explained above, backdraft (or sidedraft) fume extraction is more effective than downdraft for weld fume control. If the table will be used primarily for manual welding and other thermal processes, look for a unit that utilizes a backdraft plenum for weld fume capture.

- Extraction power: The weld fume extractor component of the table is usually measured in cubic feet per minute (CFM). Make sure the CFM rating is sufficient for your welding tasks and will provide effective extraction across the full width of the table.

- Work surface: The size and design of the table play a pivotal role in its functionality. Ideally, the table surface should be robust, often constructed from thick steel, to handle the demands of welding. It’s also important that the table size aligns with the typical size of your workpieces and offers ample space for comfortable movement.

- Filtration: An efficient filter system is the heart of any good fume extraction table. Welding produces very small, submicron particulate that requires a filter with high filtration efficiency. Look for filters with a rating of MERV 15 or higher for maximum filtration.

- Filter cleaning: A filter pulsing system can go a long way toward extending the life of the air filters in your welding booth. Some welding tables with fume extraction also include a compressed air filter pulsing system to pulse excess dust off the filters and into the collection bin. Look for one with an on-board air tank for a truly stand-alone unit.

- Noise levels: Some weld fume extraction systems are pretty noisy, which can reduce comfort levels for operators in an already-noisy work environment. Acoustic silencing can significantly reduce perceived noise levels and improve operator comfort.

- Spark arrestance: Welding produces a lot of sparks, which can result in a significant fire risk if sparks make it into the filter system of the weld booth. A spark control system is advisable for welding tables with built-in fume extraction. Some welding booths come with built-in spark control, often in the form of a metal mesh spark trap over the intake plenum for the fume extraction system.

- Maintenance requirements: Consider maintenance requirements for the welding booth. How easy is it to access and clean out the duct collection chamber or bin? How easy is it to change the filters? How long can filters be expected to last under your expected operating conditions? Choose a unit with features that make it easy to maintain and ensure optimal filter life.

- Operation: Look for a welding table with simple, plug-and-play operation and intuitive controls.

- Movability: How easy will the welding table be to move if your production needs change? While welding tables with fume extraction are not generally considered truly “portable,” some are easier to move than others. Movability will need to be considered alongside other considerations, such as work surface size and durable construction.

- Durability: A welding table should be made of heavy-duty steel and manufactured for high durability under tough operating conditions. Make sure the table is sturdy enough to support heavy weldments.

- Extras: The weld table should be designed to fit your welder’s needs and workflows. Make sure there is ample space underneath for the welding machine and peripherals. The welding table may include accessories such as storage space, built-in LED lighting, a power supply to plug in equipment, and sliding curtains.

- Warranty and support: Lastly, a comprehensive warranty and robust customer support can be invaluable, especially when investing in high-end welding tables with integrated weld fume extraction systems. This not only provides peace of mind but also ensures that any issues will be promptly addressed. Look for a company that stands behind its equipment and offers reliable support.

Finding the Best Welding Tables with Fume Extraction

Choosing the right welding table with fume extraction is not merely about securing an equipment purchase—it’s about prioritizing the health of your welders, ensuring operational efficiency, and making a long-term investment in the sustainability and growth of your business. By carefully considering your immediate needs, future growth, and the nuances of different fume extraction systems, you’ll be better positioned to make a well-informed decision.

RoboVent offers high-performance welding tables with fume extraction, including the VentBoss S200 Series of fume extraction systems. At an ample 4’ or 5’ wide, these workhorses are a favorite of weld schools and small fabrication shops.

We can help you find the right weld fume extraction table for your requirements. Talk to a RoboVent solutions expert to find your perfect welding table.

Contact Us With Your Questions!

SUBSCRIBE TO

BLOG UPDATES