HI-VAC INDUSTRIAL CLEANING SYSTEM

HANDS-OFF COLLECTION

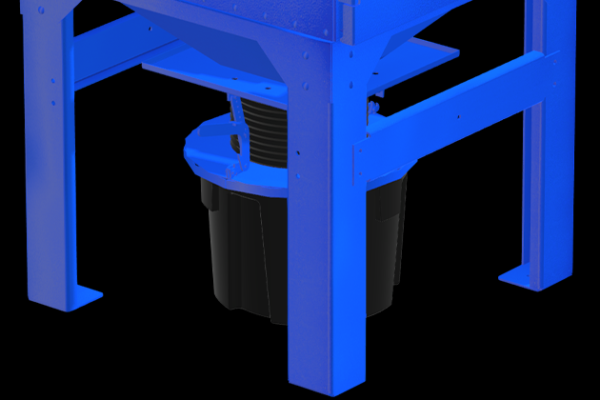

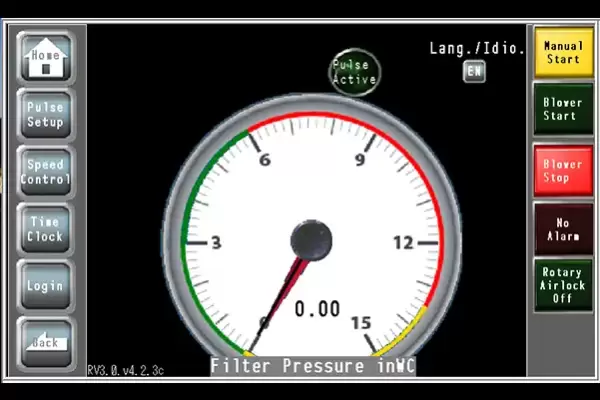

Cleaning out overhead dust collectors just got a whole lot easier. The RoboVent Hi-Vac Industrial Cleaning System is a rugged centralized vacuum that can be permanently attached to your dust collectors for easy, automated clean out. The high-vacuum system collects particulates from all of your dust collectors into a centralized bin for easy disposal. It can also be configured as an industrial-strength central vac for general facility cleaning.

- Reduce dust collector maintenance time and costs

- Eliminate the need for ladders or scaffolding to clean out collection bins on ceiling-mounted dust collectors

- Reduce exposure to harmful particulates when cleaning out collectors or conducting general facility cleaning

- Can be used with Vortex, Senturion and Spire dust collectors

A TOUGH CENTRAL VAC FOR YOUR DIRTIEST JOBS

The RoboVent Hi-Vac Industrial Cleaning System can do more than clean out your dust collectors! With additional piping and vacuum valves, it becomes a heavy-duty central vac system to replace your shop vac or other portable units. The system is tough enough to handle industrial debris (including grinding dust, nuts, bolts and washers, etc.) and is easy to customize for your needs and applications.

- Reduce time and effort for cleaning production areas and emptying multiple portable vacuum units

- Prevent harmful dusts from becoming airborne during typical broom-cleaning or bin emptying and reduce exposure to harmful particulates such as silica dust

- Reduce “trip and fall” hazards and workplace accidents common with portable equipment

- Improve workplace cleanliness, employee morale and public image

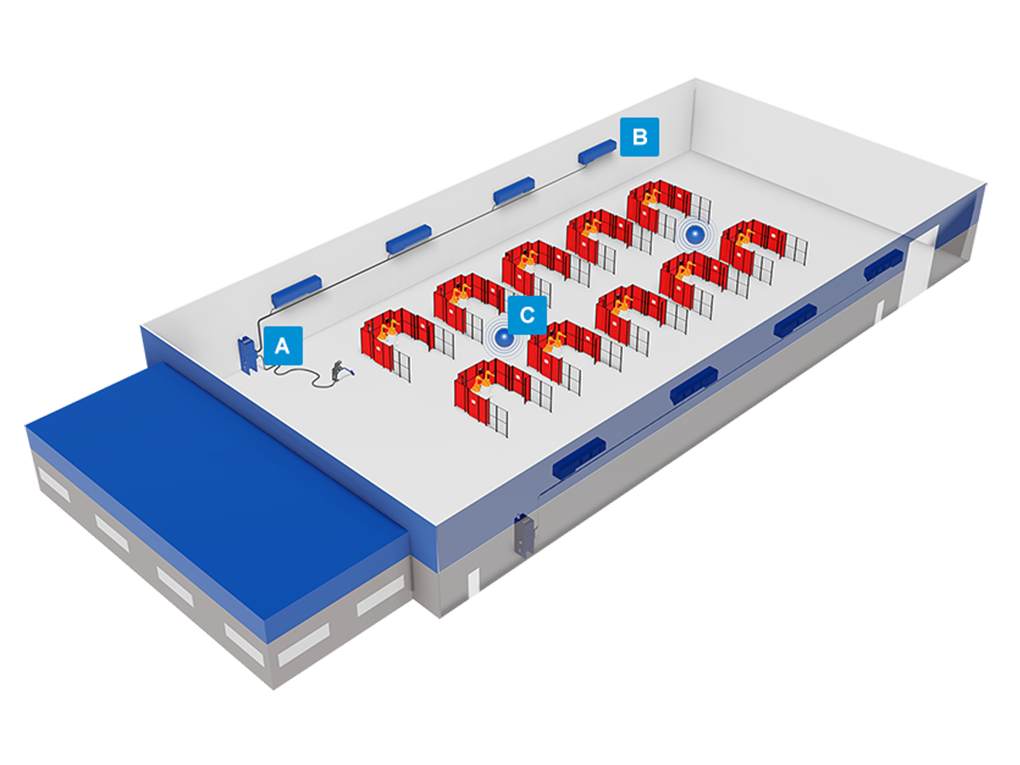

HOW IT WORKS

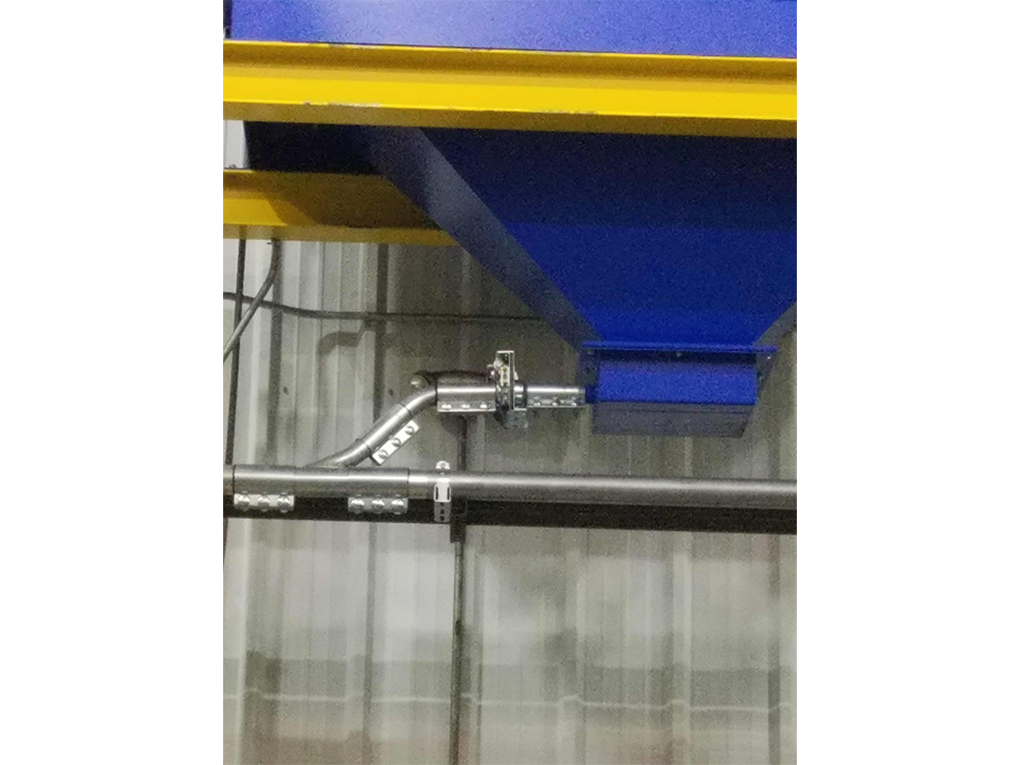

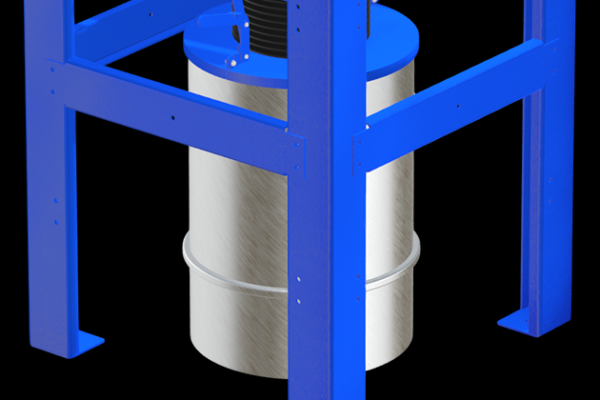

HI-VAC INDUSTRIAL CLEANING SYSTEM: The RoboVent Hi-Vac Industrial Cleaning System is a rugged centralized vacuum that can be attached directly to your dust collection system for easy collection bin clean out. The central vac system eliminates the need for ladders or scaffolding to clean out collection bins on ceiling-mounted dust collectors.

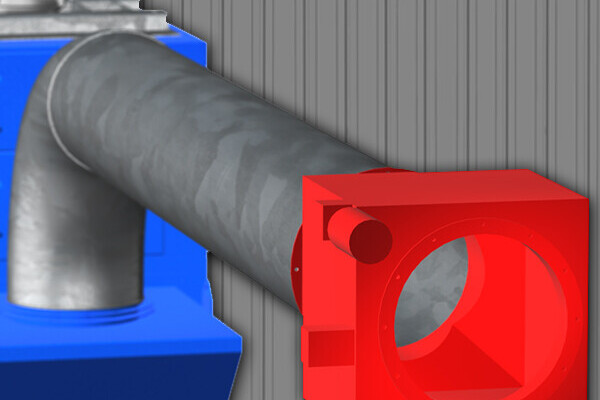

AIR FILTRATION UNITS: Dust collectors filter particulates out of the air and return clean air to the facility. The Hi-Vac Industrial Cleaning System connects directly to units such as the Vortex.

EQ AIR QUALITY MONITORING SYSTEM: With the RoboVent eQ Air Quality Monitoring System, your dust collection equipment is on when you need it, and off when you don’t. eQ continually monitors the air quality in your facility and automatically regulates your RoboVent system’s airflow in response to particulate levels.

SYSTEM COMPONENTS

- Piping is installed throughout the production area to provide easily accessible plug-in points wherever they are needed.

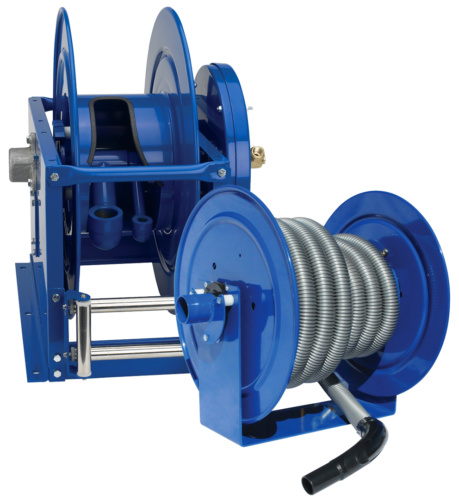

- Hoses can be up to 45 ft. (15 m) in length and come in several diameters.

- Accessories are available for a variety of cleaning needs, including brushes, crevice tools, nozzles and extension wands.

- Vacuum hose reels keep hoses out of the way and accessible.

- Vacuum valves can be fitted with automatic start/stop switches, which activate the main vacuum systems when hoses are plugged in. (Optional)

- Bin balance kit allows for the bin to be fitted with heavy-duty plastic sack for ease of removal of collected waste.

DROP US A LINE

Contact RoboVent today to start building your custom dust collection system.