Spire360™ Series - Ambient Air Filtration Systems

DISCONTINUED; SERVICE AND PARTS STILL AVAILABLE

Need a powerful ambient air filtration system? Spire360™ has been discontinued, but we can still help you find the right ambient solution for your facility. Whether you need a traditional ducted push-pull system or a ductless floor-mounted system, we’ve got you covered.

WE RECOMMEND:

THE SPIRE360™ SERIES IS:

SMALL FOOTPRINT: Our floor-saving design takes up about the same amount of space as a wire barrel. And since there is no ductwork to install, it’s less intrusive and won’t interfere with overhead cranes or production equipment.

ENERGY EFFICIENCY: Filtering and recycling factory air keeps heated or cooled air in and lowers overall energy and operating costs.

REGULATORY COMPLIANCE: Ambient filtration does a better job of clearing contaminants from the air than traditional ventilation, resulting in higher employee comfort and better compliance with health and safety regulations. Since contaminants are removed rather than simply blown out the facility, it will also ensure compliance with tightening emissions regulations and future Acceptable Point of Impingement Concentration limits.

EASY INSTALL: Spire360 is faster and easier to install than traditional ducted systems for displacement ventilation or ambient filtration. Since the Spire units have a very small footprint, it's easy to find space for them.

VERY LOW MAINTENANCE: Everything is easily accessible for fast filter changes and maintenance—no special tools required.

FLEXIBILITY: Whenever you need to change your floor configuration, Spire360 is easy to move right along with your production equipment.

HOW IT WORKS

DEFLECTOR PLATES: Deflector Plates within the top of the dust cabinet which protect filters from particulate abrasion, creates a high-velocity airstream around the filters to bring more dust into the containment chamber.

PULSING SYSTEM: Pulse nozzles are engineered to create high level shock wave through the entire filter dislodging dust from the filter pleats sending the captured dust to the dust holding bin.

PLEATLOCK FILTERS: RoboVent’s new PleatLock technology has been engineered to outlast even the toughest competitor filter. With added dimples within the pleats, there is up to 35% more media space to capture more particulate, allowing for longer time between filter changes. This saves time and money!

ePro CONTROLS: The new 7” full-color, HMI Control Panel is easy to see, easy to use and easy to understand while helping to keep the system running smoothly and operators informed. The Control Panel is mounted in the electrical control box which can be installed on the side of the unit or tethered to where it is more convenient.

eDrive™ AUTOMATIC VFD: The eDrive constantly monitors airflow and automatically adjusts the motor RPM to compensate for filter loading. Energy peaks and valleys are evened out and energy usage is cut by 20% to 30%, while filter life is extended by as much as 30%.

SAFESENSOR™ PARTICULATE MONITORING: SafeSensor is the Spire’s advanced particulate-monitoring device that can detect leaks past the filters. If one should occur, SafeSensor will shut the equipment down and trigger an alarm.

SUPPREX-200™ FIRE SUPPRESSION SYSTEM – OPTION: This is a dual-stage system activated by smoke or heat. If smoke is detected, a fire damper closes, stopping all airflow and oxygen supply. If heat is detected, FM-200 gas is instantly deployed.

DUST CONTAINMENT: More dust containment (15 gallons) – which means less servicing and better performance of the unit with more consistent CFM & Static pressure. Simply pull out the drawer and dispose of the dust.

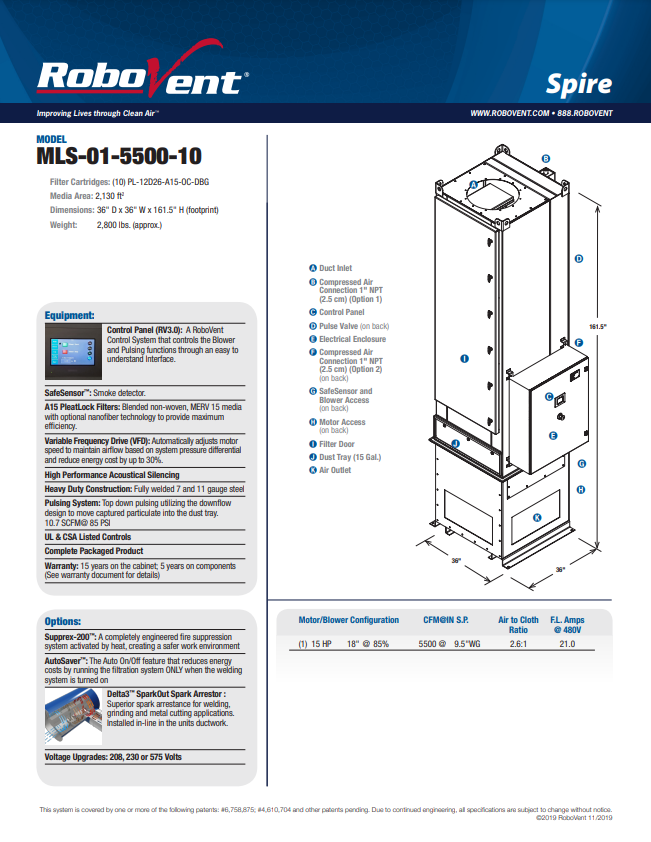

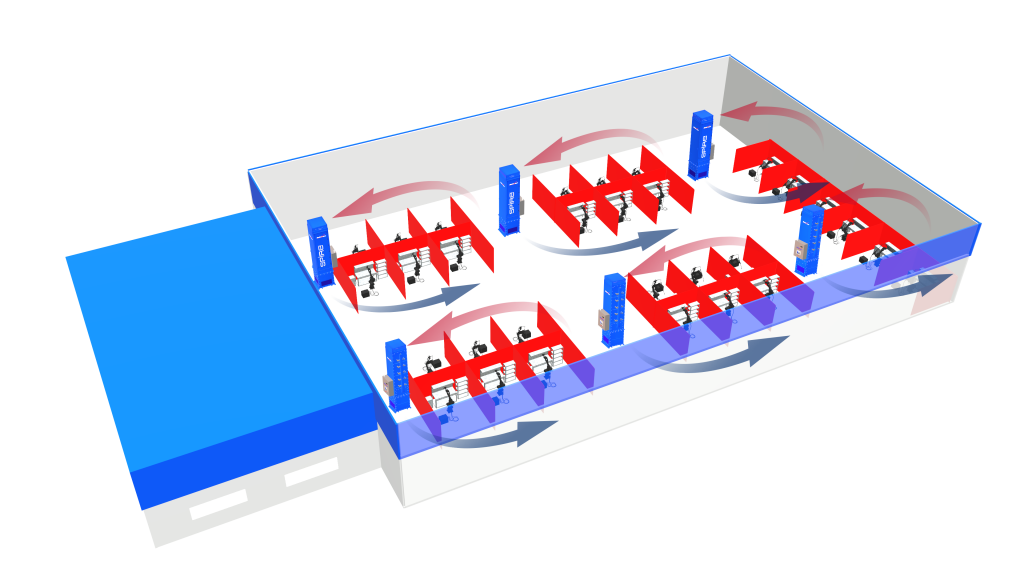

SPIRE360 CONFIGURATION

Easy to Move, Plug & Play

These units can be moved and re-configured easily throughout the plant. Without the hassle of ductwork, the Spire360 can be placed in high-dust and fume producing areas or placed strategically throughout the facility based on the airflow patterns. The small footprint allows the unit to be placed near columns or other tight spaces so long as the vertical space is available.

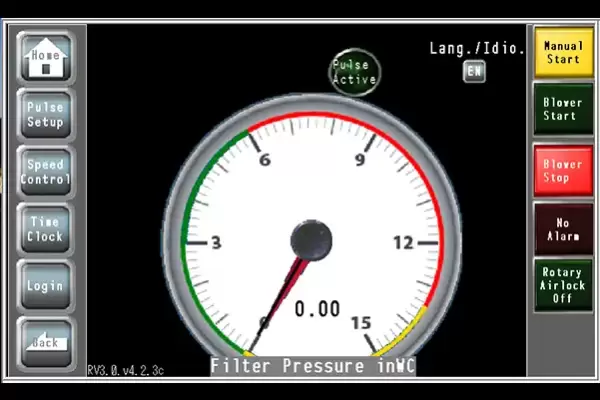

SIMPLER CONTROLS

This extra-large 7” full-color Human Machine Interface (HMI) is easy to see, easy to understand and gives you access to everything you need to keep your system running smoothly. You can control the pulse timing and trigger points, set filter service alarms, setup automatic run schedules, operate and control the blower speed, monitor filter pressure and see operation events all with the simple push of a couple of buttons.

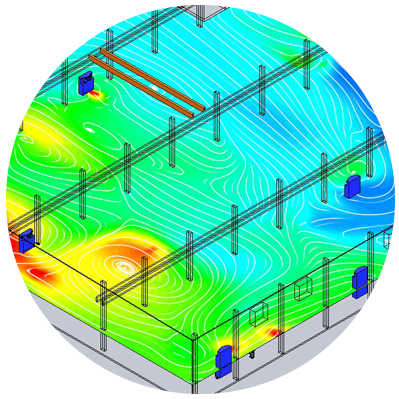

VENTMAPPING® ENGINEERING DESIGN SERVICES

Take the guesswork out of your clean air initiative

Your facility is unique. To get the best results, your whole-plant ventilation system needs to be personalized to your individual environment. That requires a thorough understanding of your facility layout, fume-generating applications, airflow patterns and physical constraints.

VentMapping is a systematic engineering and design service that uses a holistic approach to optimize your air quality system. Our comprehensive approach helps us find the safest, most effective and most efficient way to meet your goals.

DROP US A LINE

Contact RoboVent today to start building your custom dust collection system.