CLARION® CFX SERIES

A BREAKTHROUGH IN OIL MIST COLLECTION TECHNOLOGY

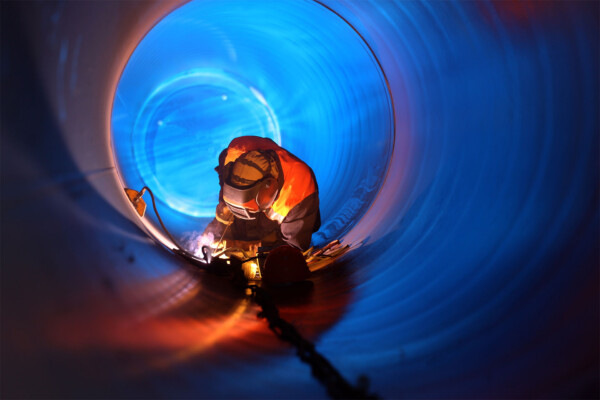

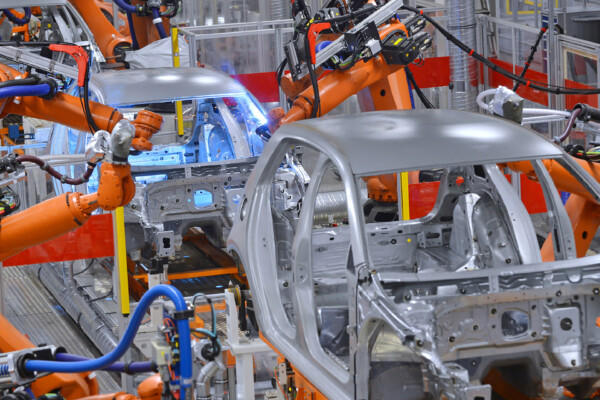

The RoboVent Clarion® Series is a revolutionary design in industrial air-cleaning equipment that efficiently separates solid particulate in oil and water in the most demanding manufacturing environments.

Traditional oil-mist collectors rely on dated technologies—such as centrifugal, pocket filters, individual cartridge or panel filters, electrostatic precipitators and others—with limited success. We believed there was a better way, so we investigated the entire process in order to redesign the way oil mist is collected.

The result is the RoboVent Clarion Series.

THE CLARION IS:

ROBUST CONSTRUCTION: A fully-welded steel cabinet with NEMA 12 super-seal doors ensures the Clarion collector will hold up to the toughest applications. The all-in-one motor/blower combination is built for energy efficiency and reliability, for performance you can count on for years to come.

SUPERIOR FILTER TECHNOLOGY: Our packed-bed filters keep working even when fully saturated, so you can count on cleaner air with less maintenance. Engineered media layers separate the oil from the air while folded layers allow separated oil to drain off, extending the useful life of the filter and reducing lifecycle costs.

EXCEPTIONAL PERFORMANCE: Our packed-bed filters keep working even when fully saturated, so you can count on cleaner air with less maintenance. Engineered media layers separate the oil from the air while folded layers allow separated oil to drain off, extending the useful life of the filter and reducing lifecycle costs.

GUARANTEED SATISFACTION: Clarion is backed by the best guarantee in the industry, with a full 15-year warranty on the cabinet and structural components. We stand behind our equipment and our system design—if it’s not working as expected, we’ll make it right.

EQUIPMENT CONFIGURATIONS

The Clarion Series can be configured to meet your specific need!

RoboVent’s Clarion CFX-1000 collectors are suited to single machining centers while the larger CFX units are modular and can be ducted to multiple systems or very large machining centers.

CFX-4000 Source Capture Unit

The Clarion CFX-4000 is built for ducting to very large machining systems, or multiple systems. This unit is modular and can be expanded to fit any application.

CFX-2000 Source Capture Unit

Ideal for medium to large machining centers, the CFX-2000 is the big brother to the CFX-1000, with the option for deeper filters. The CFX-2000 is typically used for large stand-alone machining applications.

CFX-1000 Source Capture Unit

RoboVent’s Clarion CFX-1000 is perfect for small to medium machining stations. Built to sit right on top of the machining center, it is a simple and compact solution for capturing oil mist at the source.

HOW IT WORKS

INTEGRATED CONTROLS: The CFX Source Capture Clarion unit can be very simply controlled by connecting to the dedicated terminal or interlock on the CNC machine. Upgrades to an independent motor starter and disconnect are available.

SINGLE PACKED-BED MEDIA FILTER: RoboVent’s packed-bed media filter design simplifies the filter change-out process, cutting maintenance costs. The filters come in three different depths and two different efficiency ratings. The Clarion packed-bed media filter range ensures that you will receive the right filter for your application.

SNAP-LOCK FILTER CLAMP: The Clarion double-rail clamping mechanism ensures an airtight seal for every filter. The gusseted support structure is welded to the 3/16-inch reinforced tube sheet and provides over 200 pounds of compression force on the gasket. With this system, filter change-outs are fast and easy, require no tools and can be performed from outside the filter cabinet.

eDrive™ AUTOMATIC VFD (OPTION): The eDrive constantly monitors airflow, and automatically adjusts the motor RPM to compensate for filter loading. Energy peaks and valleys are evened out, cutting energy usage by approximately 40% and increasing filter life by as much as 30%.

DROP US A LINE

Contact RoboVent today to start building your custom dust collection system.