HIGH-VACUUM FUME EXTRACTION SYSTEM

FLEXPRO™ HIGH-VACUUM SERIES: WELD FUME EXTRACTION, AIR FILTRATION AND CENTRAL VACUUM SYSTEMS

Keep dust and fumes under control with the FlexPro™ Series of high-vacuum extraction systems. From manual and robotic welding applications to general dust control and cleaning around the shop, FlexPro™ puts high-vacuum extraction power wherever you need it—delivering targeted capture for weld fumes, grinding dust, cutting particulate, and housekeeping tasks. Built for durability, performance, and flexibility, FlexPro™ High-Vacuum fume extraction system helps you maintain a cleaner, safer work environment.

FLEXPRO™: FOR POWERFUL HIGH-VACUUM EXTRACTION

FlexPro™ delivers powerful, targeted dust and fume extraction for a wide range of industrial needs—from weld fume control to general housekeeping. It’s a compact, high-performance system built for tough environments.

- Health & Safety First: Capture harmful particulates at the source to protect workers and support OSHA compliance.

- One System, Many Uses: Ideal for welding, grinding, cutting, cleaning, and more—works with fume guns, on-torch robotic extraction, and central vac systems.

- Small Footprint, Big Performance: Vertical design with integrated waste containment saves space while delivering high suction power.

- Durable by Design: Fully welded steel cabinet with 15-year warranty ensures long-lasting reliability.

- Energy Smart: VFD-driven motors and efficient airflow design help reduce energy consumption and operating costs.

APPLICATIONS: FLEXIBLE EXTRACTION FOR A WIDE RANGE OF INDUSTRIAL NEEDS

The FlexPro™ Hi-Vac Series is engineered to deliver powerful, targeted extraction wherever you need it. From source capture of weld fume at the tool to central vacuum systems for facility cleanup, FlexPro™ adapts to your process. FlexPro™ units can support a single cell or application or be ducted to multiple cells or workstations.

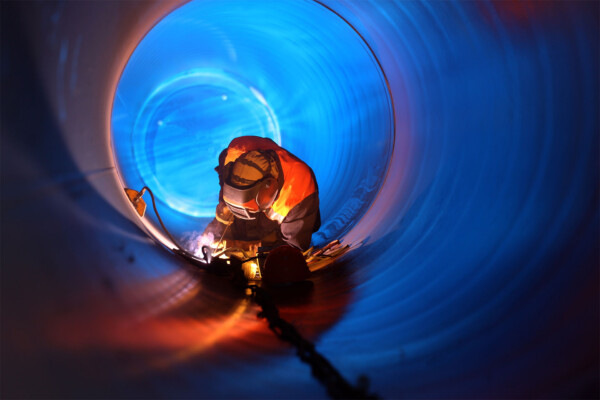

- Manual Welding: FlexPro™ provides powerful source capture for weld fumes using fume guns and suction tools, ideal for large weldments (e.g., tanks, pipes and ships), stainless steel welding and environments with overhead cranes.

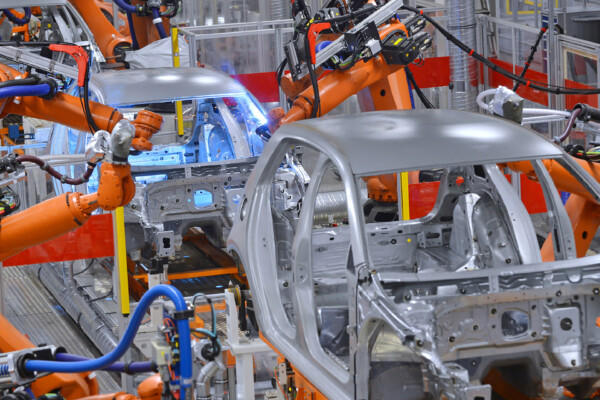

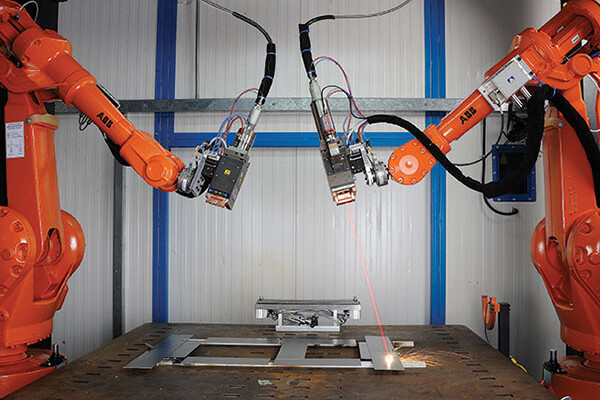

- Robotic Welding: Designed for automated lines and welding cells, FlexPro™ delivers consistent high-vacuum performance for robotic on-torch extraction.

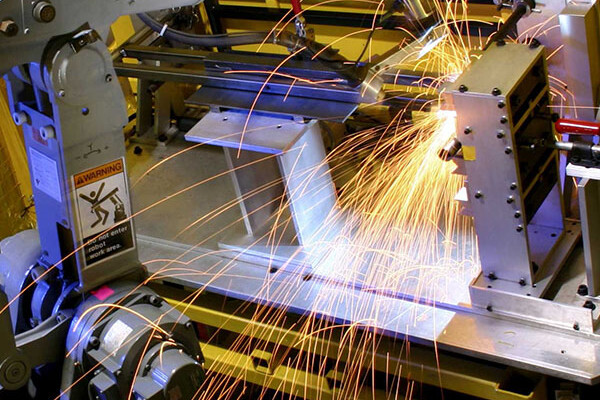

- General Dust and Fume Control: From metal cutting and grinding to food and pharma, FlexPro™ captures fine and hazardous dust at the source for cleaner, safer operations.

- Industrial Housekeeping: FlexPro™ supports central vacuum systems to manage nuisance dust and support routine industrial cleaning, helping maintain a safe, efficient and compliant facility.

HOW IT WORKS

HIGH-PERFORMANCE BLOWER: Delivers strong suction and high static pressure for effective source capture through small-diameter hoses and tools.

VFD-DRIVEN MOTOR WITH EPAD CONTROLS: Variable frequency drive and touchscreen interface allow easy, energy-efficient system operation.

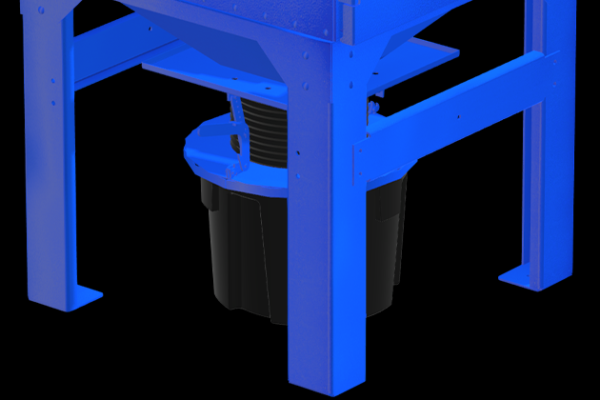

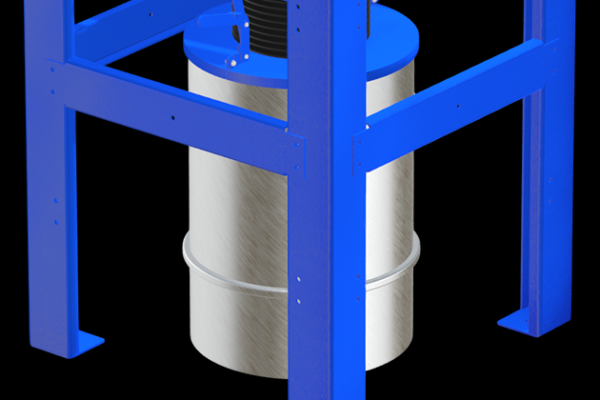

COMPACT VERTICAL DESIGN: Small footprint with integrated hopper and waste drum for space-saving performance.

DURABLE STEEL CONSTRUCTION: Fully welded 7 & 11 gauge steel, Polyester powder coat inside & out, enhances plant aesthetics & provides excellent equipment durability.

ADVANCED FILTRATION: MERV 15 or MERV 16 cartridge filters for high-efficiency particulate removal.

AUTOMATIC FILTER CLEANING SYSTEM: Automated pulsing when filters become loaded to save energy and increase filter life.

INLET PRESSURE RELIEF VALVE: Prevents harmful overpressure developing at the blower if flow becomes obstructed, preventing damage to the blower.

NOISE REDUCTION: Built-in clean air exhaust and silencer minimizes system noise for a quieter, more comfortable work environment.

INTEGRATED WASTE CONTAINMENT: Includes a 20-gallon drum for simple dust disposal.

Options:

- Full-top acoustical plenum (additional 5 dBA reduction)

- AutoSaver sensor (auto start/stop with application)

- 2nd stage filters using additional HEPA or Carbon filtration

- Fire Suppression (water sprinkler or CO2)

- Barrel level sensor

- 55-gallon steel drum waste containment

- SafeSensor particulate monitor

- Explosion Vent

- Delta3 Inline Spark Arrestor

RIGHT-SIZE FOR YOUR FACILITY

Don’t pay for extraction power you don’t need. Find the perfect FlexPro™ Hi-Vac for your needs.

HVE-175

- Model No.: HVE-175-80-1

- Configuration: 5.5 HP

- CFM @ WG: 140 @ 80

- FLA @ 480 V: 8 AMPS

- # of Filters: 1

HVE-350

- Model No.: HVE-350-80-1

- Configuration: 10 HP

- CFM @ WG: 350 @ 80

- FLA @ 480 V: 14 AMPS

- # of Filters: 1

HVE-550

- Model No.: HVE-350-80-2

- Configuration: 15 HP

- CFM @ WG: 520 @ 80

- FLA @ 480 V: 21 AMPS

- # of Filters: 2

HVE-950

- Model No.: HVE-950-80-2

- Configuration: 40 HP

- CFM @ WG: 1050 @ 80

- FLA @ 480 V: 52 AMPS

- # of Filters: 2

COMPATIBLE TOOLS AND ATTACHMENTS

The FlexPro™ Series is designed to work with a wide range of source capture tools and attachments for maximum versatility across welding, cutting, and cleaning applications.

- Fume Guns: FlexPro™ pairs perfectly with MIG Fume Extractor Guns, delivering direct-source fume capture for manual welders without restricting movement or visibility.

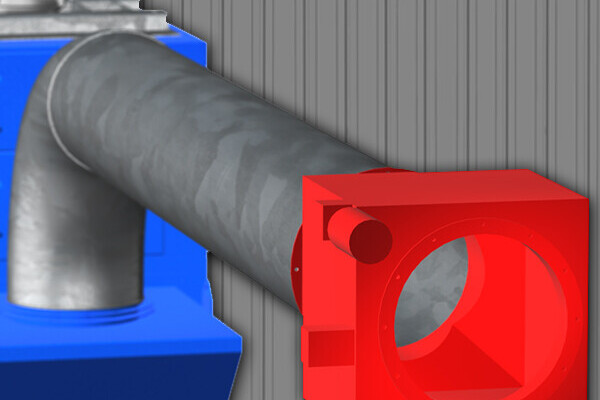

- FlexTrac™ Robotic Weld Fume Extractor: Integrate FlexPro™ with RoboVent’s FlexTrac™ hi-vac robotic arm systems for targeted fume removal in automated welding cells.

- Central Vacuum Tools: Connect to vac tools and nozzles for housekeeping and machine cleanup applications—ideal for dust removal from floors, walls, equipment, and workstations.

- Small Capture Hoods: Compatible with compact enclosures and mini-hoods used in grinding or bench-top operations.

FAQS

FlexPro™ High-Vacuum Series

What is high-vacuum dust and fume extraction?

High-vacuum (hi-vac) extraction systems generate high levels of static pressure to pull dust, fumes, and other particulates through small-diameter hoses or tools. Unlike ambient air filtration or low-vacuum systems, hi-vac units are designed for source capture—removing contaminants as they are produced at the tool tip, weld seam or dust source. This method prevents airborne hazards from spreading throughout the facility.

How is high-vacuum extraction different from low-vacuum or ambient systems?

The key difference between hi-vac and low-vac systems lies in pressure and purpose. Low-vacuum or ambient systems move large volumes of air at low static pressure to clean the air in a room or draw from large hoods. High-vacuum systems operate at much higher static pressure, delivering strong suction through narrow hoses to remove contaminants right at the source. This makes hi-vac ideal for targeted extraction in processes like welding, grinding, sanding and housekeeping.

What are the advantages of using a high-vacuum extraction system?

High-vacuum systems offer several important benefits:

- Effective Source Capture: Removes fumes and dust at the point of generation, preventing exposure and contamination.

- Improved Air Quality: Supports cleaner, healthier work environments and protects worker respiratory health.

- Space Efficiency: Eliminates the need for large overhead hoods or bulky ductwork, preserving valuable workspace.

- Versatility: Compatible with fume guns, extraction tools, robotic cells, and central vacuum systems.

- Energy Efficiency: Targeted extraction uses less air volume, reducing energy costs over time.

- Safety & Compliance: Helps meet OSHA exposure limits, NFPA combustible dust standards, and other safety requirements.

When should I use a high-vacuum extraction system?

Hi-vac systems are ideal when:

- You need to collect contaminants directly at the point of generation.

- Overhead clearance is limited by cranes, lighting, or other equipment.

- Welding, grinding, sanding, or cutting operations generate dense fumes or fine dust.

- You require a flexible system for both source capture and industrial cleaning.

- You are working with hazardous, combustible, or regulatory-sensitive materials (e.g., stainless steel, pharmaceuticals, battery dust, etc.).

What kinds of tools and applications are compatible with hi-vac systems?

High-vacuum systems can be used with:

- Manual or robotic welding guns with integrated extraction

- Suction nozzles and tubes for grinding and sanding

- Enclosed hoods for small, high-dust operations

- Central vacuum lines for facility cleaning and housekeeping

- Specialized tools in food, pharma, and battery manufacturing for close source capture of fine or hazardous particulate

DROP US A LINE

Contact RoboVent today to start building your custom dust collection system.