DUST AND FUME COLLECTION CHALLENGES IN THE RAILWAY EQUIPMENT INDUSTRY

Since the 1970s, the Occupational Safety and Health Administration (OSHA) has issued and enforced air quality regulations in manufacturing. Railway equipment’s reliance on welding means the industry must pay special attention to these air quality standards. For example, the exposure limit for manganese—a common component of weld fumes—is being reconsidered in the regulatory world. The American Conference of Governmental Industrial Hygienists (ACGIH) has recommended a radical reduction in the exposure limit for manganese. While OSHA has not adopted this limit, the agency listens closely to the ACGIH and often follows its lead, at least to a degree.

Since the 1970s, the Occupational Safety and Health Administration (OSHA) has issued and enforced air quality regulations in manufacturing. Railway equipment’s reliance on welding means the industry must pay special attention to these air quality standards. For example, the exposure limit for manganese—a common component of weld fumes—is being reconsidered in the regulatory world. The American Conference of Governmental Industrial Hygienists (ACGIH) has recommended a radical reduction in the exposure limit for manganese. While OSHA has not adopted this limit, the agency listens closely to the ACGIH and often follows its lead, at least to a degree.

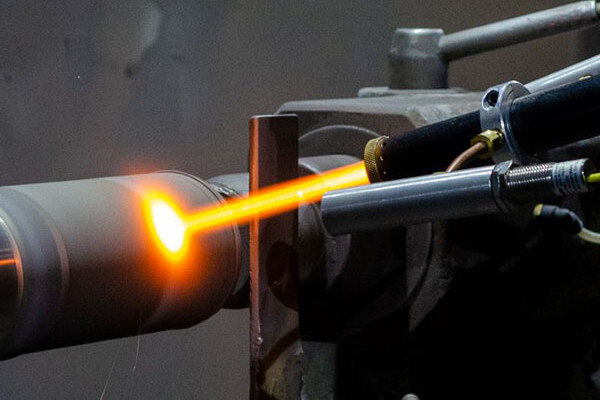

Manganese is a good example of a substance that manufacturers need to control. While manganese is actually a necessary part of one’s diet, when inhaled at certain concentrations, it is highly toxic. Because these particles are extremely small—due to the high temperatures involved in welding—they are easily inhaled. Exposure to inhalable manganese in even small quantities can affect memory and reaction times. Chronic exposure can have serious effects on the central nervous system, including manganism. This condition has symptoms similar to Parkinson’s Disease.

Dust collection is an important priority for manufacturers, as well, for both workers’ health and for regulatory compliance. Metal cutting produces dusts that contain toxic metals, many of which are regulated by specific OSHA standards. These substances can be very dangerous to workers, even in small quantities. Some dust standards have seen regulatory changes. For example, in 2016, the standard for crystalline silica was dramatically lowered by OSHA. Failure to meet these standards leaves a manufacturer susceptible to significant fines and possible reputational harm. Most importantly, a failure to maintain clean air imperils workers’ health.

A clean and pleasant work environment is crucial for recruiting and retaining skilled workers, as well. Workers and job applicants know dirty air when they see it (and smell it). As most manufacturers know, the job of recruitment is getting more and more difficult—the American Welding Society estimates that manufacturing will see a shortage of 290,000 skilled welders by 2020. Employers must maintain a pleasant and safe workplace in order to attract the best workers.

Related Resources

SOLUTIONS FOR DUST AND FUMES IN THE RAILWAY EQUIPMENT INDUSTRY

RoboVent has almost three decades of experience solving air quality challenges in manufacturing environments. Our engineers got their start controlling weld fumes in the automotive industry and since have grown to address dust and fumes at every scale, from the smallest operation to the largest. RoboVent manufactures its own equipment, ensuring end users the best quality and performance.

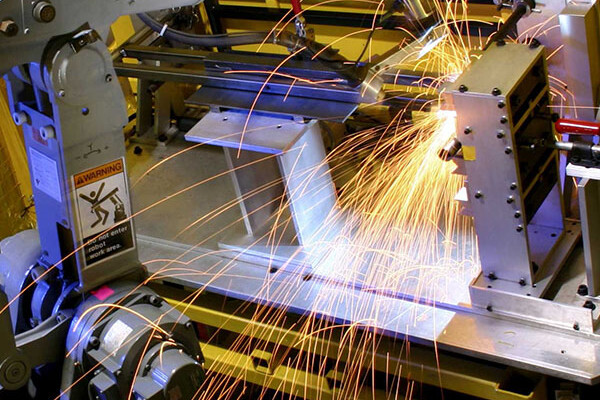

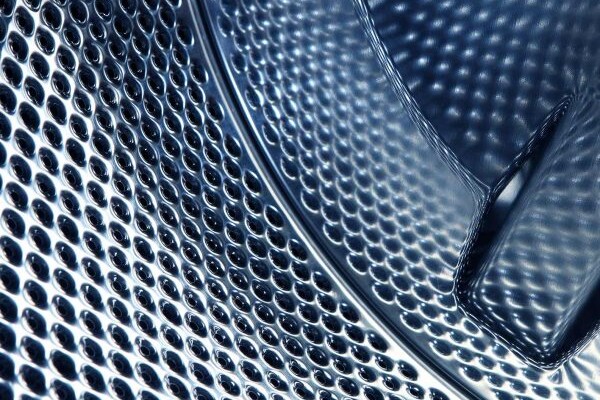

The railway equipment industry requires air quality solutions of all kinds, from source capture for specific applications to ambient capture across entire facilities. RoboVent’s line of portable collectors lets manufacturers capture dust and fumes at their point of creation. These collectors use fume arms or hoods to make sure welders are protected, as well as everyone in the facility. These collectors are especially useful when welding or cutting large components.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.