FEATURES

RoboVent is an innovation leader for the dust collection and air filtration industry. We are continually working to develop new features for our dust collectors to make them safer, more energy efficient, easier to maintain and easier to use.

(Standard and optional features will vary by dust collector model.)

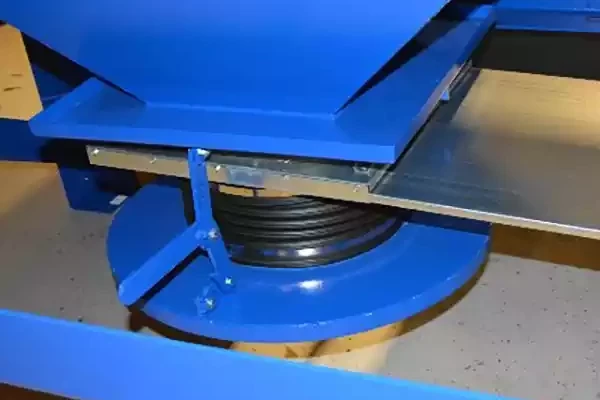

FIRE PROTECTION FOR INDUSTRIAL DUST COLLECTORS

Prevent industrial dust collector fires with fire safety elements including fire suppression systems, fire dampers, sprinkler systems and smoke detectors. Dust collector fires are a serious hazard, especially when working with combustible dusts or spark-producing processes. We can help you choose the right fire suppression system for your dust collector based on your dust type, collector model and application.

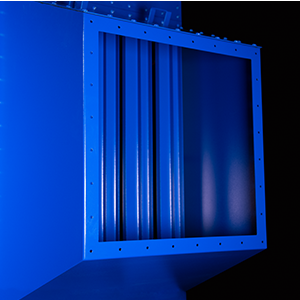

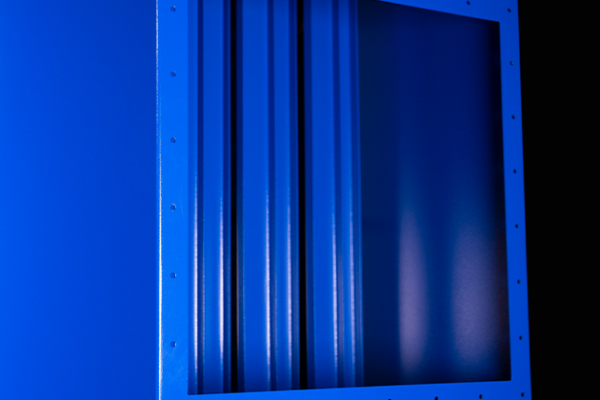

Damper

Sprinkler Head Port

Clean Agent Gas Fire Suppression

EXPLOSION PROTECTION FOR INDUSTRIAL DUST COLLECTORS

Protect your people and facility from an industrial dust collector explosion with our deflagration systems. RoboVent is your combustible dust expert. We can help you conduct a Dust Hazard Analysis and design a deflagration system that will prevent a dangerous dust collector explosion from propagating through your facility. NFPA-compliant deflagration systems are available for ST-1 and ST-2 combustible dust.

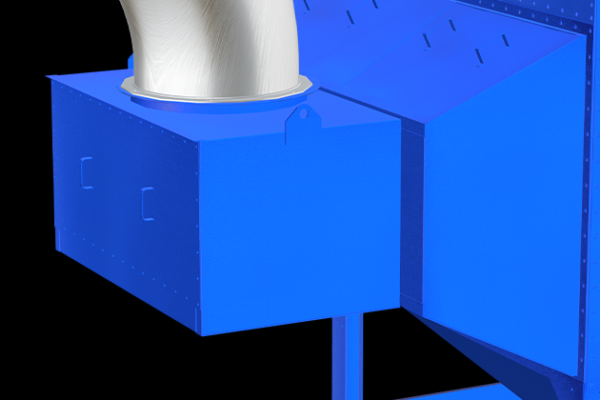

Deflagration System

Rotary Airlock

Explosion Vent

Isolation Valve

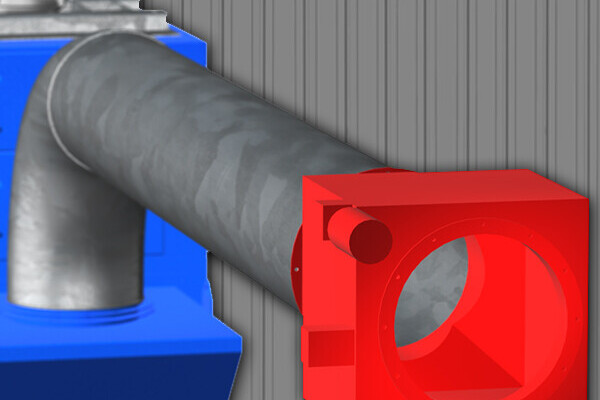

SPARK CONTROL FOR INDUSTRIAL DUST COLLECTORS

If you are working with spark-producing processes such as welding, cutting or grinding, a spark arrestance system is a must. A spark arrestor reduces the risk of a dust collector fire by preventing sparks from reaching the filter chamber. It can be installed directly at the dust collector intake or inline with your ductwork. Talk to us about your spark protection options for your industrial dust collector.

Spark Arrestors for Dust Collection and Air Filtration Equipment

Delta3™ Sparkout Spark Arrestor

Delta3™ Inline Spark Arrestor

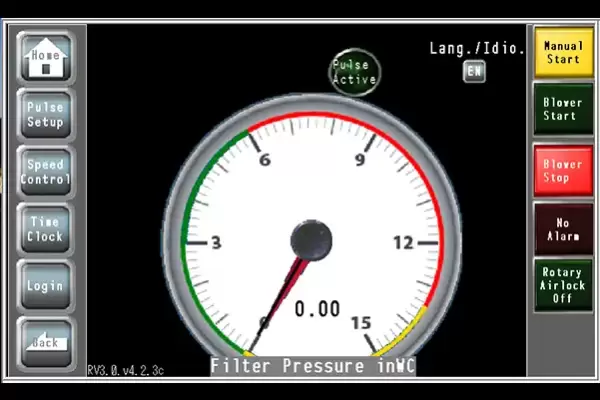

INDUSTRIAL DUST COLLECTOR CONTROL SYSTEMS

Our dust collector control systems make it easy to operate your dust collector and optimize performance. Full-color control panels provide complete visibility into dust collector performance, including the blower, the filter differential pressure and the filter pulsing system. The ePro 7” full-color HMI is available in ground-mounted, collector-mounted and wall-mounted configurations. ePad is a simple, fully integrated control system.

Control Panel

ePad Control System

ENERGY EFFICIENCY FEATURES FOR INDUSTRIAL DUST COLLECTORS

An industrial dust collector uses a significant amount of energy in a manufacturing environment. You can reduce energy consumption for your dust collector by choosing energy-efficient options such as variable frequency drive (VFD) and control systems with automated start/stop. The right features could help you reduce energy use for your dust collector by up to 30%. Talk to us to learn how you can save energy.

AutoSaver™ Power Usage Sensor

eDrive™ Automatic VFD

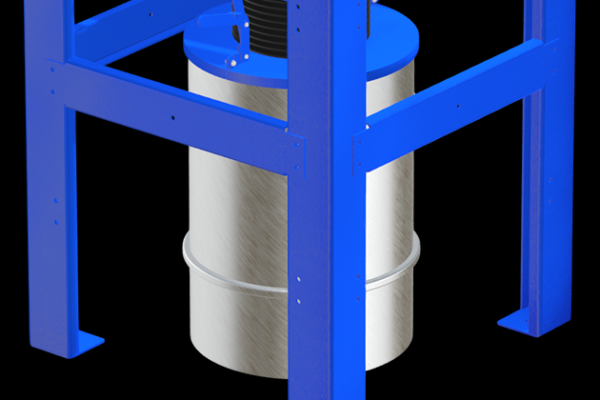

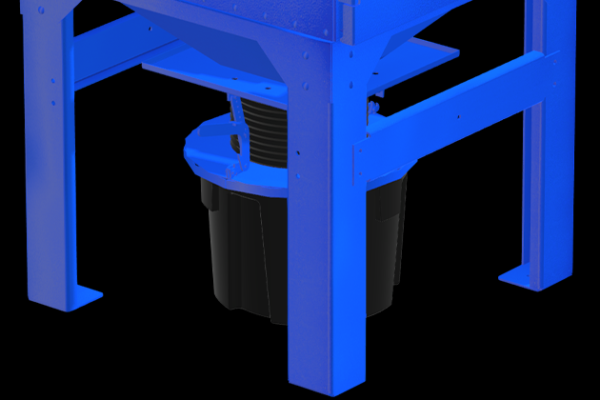

CONTAINMENT & BIN MAINTENANCE FOR INDUSTRIAL DUST COLLECTORS

Our industrial dust collector containment systems are designed for easy maintenance and effective containment of dust, so it will not escape back to the facility. Choose a simple dust tray for light applications or facilities where dust collector height is a concern. Or, upgrade to a 20- or 55-gallon drum for heavier applications. Accessories like the SuperSeal Gate and Barre Level Sensor simplify maintenance and reduce downtime.

Dropout Box

55-Gallon Drum

20-Gallon Drum

Dust Tray

SuperSeal™ Hopper Gate

Barrel Level Sensor

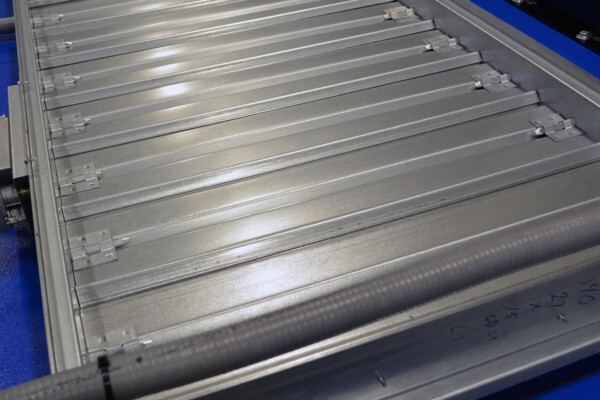

INDUSTRIAL DUST COLLECTOR FILTER PROTECTION & MAINTENANCE

Extend the life of your industrial dust collector filters and make filter changes a snap with these innovative filter features. Vertical filter design and the most advanced filter pulsing system available maximize the life of your filters to save money and reduce downtime. The innovative Snap-Lock™ filter system makes filter changes a snap. We can help you select the right filters and accessories to maximize dust collector performance.

Service Platform

Snap-Lock Filter Clamp

Vertical Filter Design

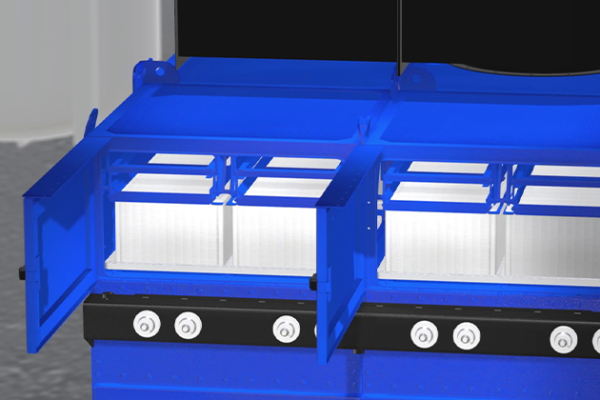

AFTER-FILTERS FOR INDUSTRIAL DUST COLLECTORS

Your industrial dust collector can perform double-duty for collection of odors, gases, vapors, pathogens or ultrafine particulate with the right after-filters. After-filters are added between the filter chamber and exhaust plenum to collect contaminants your dust collector filters miss. HEPA after-filters collect ultrafine particulate, including dust, pollen, mold and bacteria. Activated carbon is used for smoke, odors, vapors and gases.

Activated Carbon After-Filter

HEPA After Filter

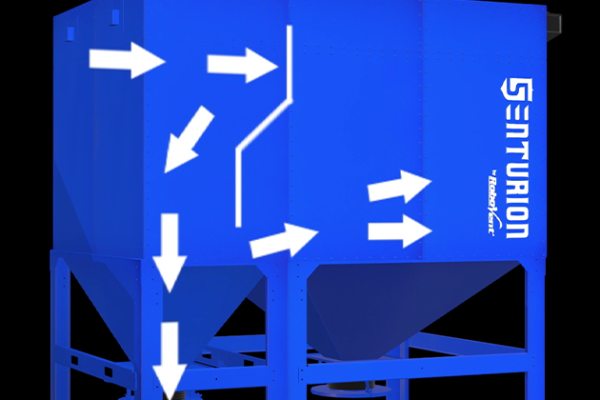

INDUSTRIAL DUST COLLECTOR INTAKES & PLENUMS

Many of our industrial dust collectors can be equipped with different intakes for challenging or specialty applications. For coarse, abrasive dust, upgrade to an abrasion-resistant intake or a full drop-out box to remove heavier particulate before it hits the filters. The Vortex Exhaust Plenum transforms your dust collector into an ambient air filtration system. See which intake options are right for you.

Abrasion-Resistant Intake

Standard Intake

OTHER INDUSTRIAL DUST COLLECTOR FEATURES

At RoboVent, we’re always working to create new features to improve industrial dust collector safety and performance. We can put together a package of features for your industrial dust collector that works for you and your applications.